Nekuwedzera kwekuziva nezvekuchengetedzwa kwezvakatipoteredza, kusimudzirwa uye kurudziro yesimba idzva pasi rose yakaita kuti kusimudzirwa nekushandiswa kwemotokari dzemagetsi kuve pedyo. Panguva imwecheteyo, izvo zvinodikanwa zvekuvandudzwa kwehuremu hwezvinhu zvemotokari, kushandiswa kwakachengeteka kwealuminium alloys, uye yavo yemhando yepamusoro, saizi uye zvivakwa zvemuchina zviri kuramba zvichikwira nepamusoro. Kutora EV ine huremu hwemotokari hwe1.6t semuenzaniso, iyo aruminiyamu alloy zvinhu ingangoita 450kg, inoverengera inosvika makumi matatu%. Hurema hwepamusoro hunoonekwa mukugadzira extrusion process, kunyanya dambudziko rezviyo zvakakasharara pane zvemukati nekunze, zvinokanganisa zvakanyanya kufambira mberi kwekugadzirwa kwealuminium profiles uye kuita bhodhoro rekuvandudza kwavo application.

Kune ma profiles akawedzerwa, dhizaini uye kugadzirwa kweiyo extrusion kufa kwakakosha zvakanyanya, saka kutsvagisa uye kusimudzira kweanofira EV aluminium profiles kwakakosha. Kukurudzira zvesainzi uye zvine musoro kufa mhinduro zvinogona kuwedzera kuvandudza mwero wakakodzera uye extrusion chigadzirwa cheEV aluminium profiles kuti isangane nemusika kudiwa.

1 Product Standards

(1) Zvishandiso, kurapwa kwepamusoro uye anti-corrosion yezvikamu uye zvikamu zvichaenderana nezvinodiwa zveETS-01-007 "Technical Requirements for Aluminium Alloy Profile Parts" uye ETS-01-006 "Technical Requirements for Anodic Oxidation Surface Treatment".

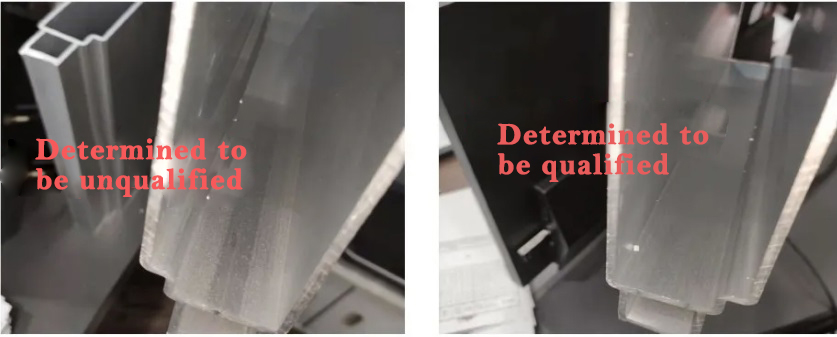

(2) Kurapwa kwepamusoro: Anodic oxidation, iyo yepamusoro haifanirwe kunge ine coarse zviyo.

(3) Pamusoro pezvikamu hazvibvumirwi kuva nezvikanganiso zvakadai sekuputika uye makwinya. Izvo zvikamu hazvibvumidzwe kusvibiswa mushure mekuita oxidation.

(4) Zvinhu zvakarambidzwa zvechigadzirwa zvinosangana nezvinodiwa zveQ/JL J160001-2017 “Zvinodiwa Zvezvinhu Zvakarambidzwa uye Zvinorambidzwa muMotokari Zvikamu uye Zvishandiso”.

(5) Mechanical performance zvinodiwa: tensile simba ≥ 210 MPa, goho simba ≥ 180 MPa, elongation mushure mekutsemuka A50 ≥ 8%.

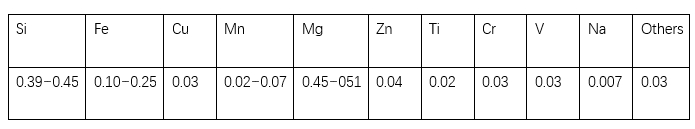

(6) Zvinodiwa zvealuminium alloy kuumbwa kwemotokari itsva dzesimba zvinoratidzwa muTebhu 1.

2 Optimization uye kuenzanisa kuongorora kwe extrusion kufa chimiro Makuru-makuru ekucheka magetsi anoitika

(1) Traditional solution 1: ndiko kuti, kuvandudza mberi extrusion die design, sezvinoratidzwa mumufananidzo 2. Maererano nemafungiro ekugadzirwa kwemazuva ose, sezvinoratidzwa nemuseve mumufananidzo, nzvimbo yepakati pembabvu uye sublingual drainage nzvimbo inoshandiswa, iyo yepamusoro uye yakadzika madhiraini ndeye 20 ° kune rumwe rutivi, uye kureba kwemvura H15 mm chikamu cheriten chinoshandiswa kupa molluminum. Iyo sublingual banga isina chinhu inotamiswa pakona yekurudyi, uye iyo yakanyungudutswa aluminium inoramba iri pakona, iri nyore kugadzira nzvimbo dzakafa nealuminium slag. Mushure mekugadzirwa, inosimbiswa neoxidation kuti nzvimbo yacho inonyanya kutarisana nematambudziko ezviyo.

Aya anotevera ekutanga optimizations akaitwa kune yechinyakare mold kugadzira maitiro:

a. Kubva pane iyi mold, takaedza kuwedzera aluminium kugovera kune mbabvu nekudyisa.

b. Pahwaro hwekudzika kwepakutanga, iyo sublingual banga isina kudzika yakadzika, kureva, 5mm inowedzerwa kune yekutanga 15mm;

c. Hupamhi hweiyo sublingual isina chinhu blade inowedzerwa ne2mm zvichibva pane yekutanga 14mm. Mufananidzo chaiwo mushure mekugadzirisa unoratidzwa mumufananidzo 3.

Mhedzisiro yemhinduro inoratidza kuti mushure mekuvandudzwa kutatu kwekutanga, hurema hwezviyo huchiripo mumaprofile mushure mekurapwa kweoxidation uye hazvina kugadziriswa zvine musoro. Izvi zvinoratidza kuti chirongwa chekutanga chekuvandudza hachisati chakwanisa kuzadzisa zvinodiwa zvekugadzira zvealuminium alloy zvinhu zveEVs.

(2) New Scheme 2 yakatsanangurwa zvichibva pane yekutanga optimization. Iyo mold yakagadzirwa yeNew Scheme 2 inoratidzwa muMufananidzo 4. Maererano ne "simbi fluidity musimboti" uye "mutemo wekushomeka kushoma", iyo yakagadziridzwa yemotokari zvikamu mold inotora "yakavhurika kumashure gomba" chirongwa chekugadzira. Iyo mbabvu nzvimbo inoita basa mukukanganisa yakananga uye inoderedza friction resistance; nzvimbo yekudya yakagadzirirwa kuve "hari yakavharwa-yakaumbwa" uye nzvimbo yebhiriji inogadziriswa kuita mhando yeamplitude, chinangwa ndechekudzikisa kupesana kwekupokana, kuvandudza fusion, uye kuderedza extrusion pressure; bhiriji rakanyura zvakanyanya sezvinobvira kudzivirira dambudziko rezviyo zvakakora pasi pebhiriji, uye hupamhi hwebanga risina chinhu pasi perurimi rwebhiriji pasi ≤3mm; mutsauko wenhanho pakati pebhandi rekushanda uye bhandi rekushanda rinofa riri ≤1.0mm; banga risina chinhu pasi perurimi rwepamusoro rinofa rakatsetseka uye rakafanana rakashandurwa, risina kusiya chivharo chekuyerera , uye gomba rekugadzira rinorohwa zvakananga sezvinobvira; bhandi rinoshanda pakati pemisoro miviri iri pakati pembabvu yemukati ipfupi sezvinobvira, kazhinji inotora kukosha kwe1.5 kusvika ku2 nguva yemadziro emadziro; iyo drainage groove ine shanduko yakatsetseka kuti isangane nezvinodiwa zvesimbi yakakwana yealuminium mvura inoyerera ichipinda mugomba, ichipa yakanyatso kusanganiswa mamiriro, uye ichisiya pasina nzvimbo yakafa chero nzvimbo (banga risina chinhu kuseri kwepamusoro kufa haripfuuri 2 kusvika 2.5mm). Kuenzanisa kweiyo extrusion die chimiro pamberi uye mushure mekuvandudzwa kunoratidzwa muMufananidzo 5.

(3) Chenjerera kune kuvandudzwa kwemaitiro ekugadzirisa. Nzvimbo yebhiriji yakakwenenzverwa uye yakabatana zvakanaka, mabhandi epamusoro uye epasi anofa anoshanda akati sandara, deformation kuramba yakaderedzwa, uye kuyerera kwesimbi kunovandudzwa kuti kuderedze kusaenzana. Inogona kudzvanya zvine mutsindo matambudziko akadai sembeu dzakaomarara uye welding, nekudaro ichiona kuti mbabvu inobuda uye nekumhanya kwemudzi webhiriji zvakawiriraniswa nezvimwe zvikamu, uye zvine musoro uye nesainzi kudzvinyirira matambudziko epasi senge coarse grain welding pamusoro peiyo aluminium profile. Kuenzanisa kusati kwaitwa uye mushure mekuvandudzwa kwemvura yekuumbwa kunoratidzwa muMufananidzo 6.

3 Extrusion maitiro

Kune 6063-T6 aruminiyamu alloy yeEVs, iyo extrusion reshiyo yekuparadzana kufa inoverengerwa kuve 20-80, uye extrusion reshiyo yeiyi aruminiyamu zvinhu mumuchina we1800t imakumi maviri nenhatu, inosangana nezvinodiwa zvekugadzirwa kwemuchina. Iyo extrusion process inoratidzwa muTafura 2.

Tafura 2 Extrusion yekugadzira maitiro ealuminium profiles yekumisikidza matanda eEV bhatiri mapaketi matsva.

Teerera kune anotevera mapoinzi kana extruding:

(1) Zvinorambidzwa kupisa zviumbwa muchoto chimwe chete, zvikasadaro tembiricha yekuumbwa ichave isina kuenzana uye crystallization ichaitika nyore.

(2) Kana kuvharwa kusina kujairika kuchiitika panguva yeextrusion process, nguva yekuvhara haifaniri kudarika maminitsi matatu, kana zvisina kudaro mold inofanira kubviswa.

(3) Hazvibvumirwi kudzoka muchoto kuti zvidziye uye wozoburitsa zvakananga mushure mekudzikiswa.

4. Mold kugadzirisa zviyero uye kushanda kwavo

Mushure memazana ekugadzirisa mold uye kuyedza mold kuvandudzwa, inotevera inonzwisisika yekugadzirisa mold inorongwa.

(1) Ita yekutanga kururamisa uye kugadzirisa kune yekutanga mold:

① Edza kunyura bhiriji zvakanyanya sezvinobvira, uye hupamhi hwezasi hwebhiriji hunofanira kunge huri ≤3mm;

② Musiyano wenhanho pakati pebhanhire rekushanda remusoro uye bhandi rekushanda rezasi mold rinofanira kuva ≤1.0mm;

③ Usasiye chivharo chekuyerera;

④ Bhandi rinoshanda pakati pemisoro miviri yechirume pambabvu dzemukati rinofanira kunge rakapfupika sezvinobvira, uye shanduko yemugero wemvura inofanira kunge yakatsetseka, yakakura uye yakatsetseka sezvinobvira;

⑤ Bhandi rekushanda remuumbi wepasi rinofanira kunge rakapfupika sezvinobvira;

⑥ Hapana nzvimbo yakafa inofanirwa kusiiwa chero kupi (kuseri kusina banga harifanire kudarika 2mm);

⑦ Gadzirisa mold yepamusoro nemakoronga ehuni mukati memukati, kuderedza bhanhire rekushanda rezasi mold uye gadzirisa kuyerera kwechivharo , kana kuti usava nevhavha yekuyerera uye kupfupisa bhanhire rinoshanda rezasi.

(2) Zvichienderana nekumwe kugadziridzwa kwekuumbwa uye kuvandudzwa kweiyo mold iri pamusoro, zvinotevera mold shanduko dzinoitwa:

① Bvisa nzvimbo dzakafa dzemisoro miviri yechirume;

② Bvisa chivharo chekuyerera;

③ Deredza mutsauko wehurefu pakati pemusoro uye yepasi kufa yekushanda nzvimbo;

④ Pfupisa iyo yakaderera kufa yekushanda nzvimbo.

(3) Mushure mekunge mold yagadziriswa uye yavandudzwa, kunaka kwepamusoro kwechigadzirwa chakapedzwa kunosvika panzvimbo yakakodzera, ine nzvimbo inopenya uye isina zviyo zvakakora, izvo zvinogadzirisa zvinogadzirisa matambudziko ezviyo zvakakasharara, welding uye humwe hurema huripo pamusoro pealuminium profiles yeEVs.

(4) Iro extrusion volume yakawedzera kubva kune yekutanga 5 t / d kusvika 15 t / d, ichivandudza zvakanyanya kushanda kwekugadzira.

5 Mhedziso

Nekudzokorodza kukwenenzvera uye kuvandudza mold yepakutanga, dambudziko guru rine chekuita nembeu yakakasharara pamusoro uye welding yealuminium profiles yeEVs yakagadziriswa zvachose.

(1) Iyo isina simba yekubatanidza yekuumbwa kwepakutanga, mutsara wepakati pembabvu, yakagadziridzwa zvine mutsindo. Nekubvisa nzvimbo dzakafa dzemisoro miviri, kudzikamisa chivharo chekuyerera, kuderedza kureba mutsauko pakati pemusoro uye yepasi kufa yekushanda nzvimbo, uye kupfupisa yepasi kufa yekushanda nzvimbo, kuremara kwepamusoro kwe6063 aruminiyamu alloy inoshandiswa mumhando iyi yemotokari, senge tsanga dzakakora uye welding, zvakakundwa.

(2) Iro extrusion volume yakawedzera kubva ku5 t / d kusvika ku15 t / d, ichivandudza zvikuru kubudirira kwekugadzira.

(3) Iyi kesi yakabudirira yeextrusion die dhizaini uye kugadzira inomiririra uye inonongedzwa mukugadzirwa kwemaprofile akafanana uye akakodzera kusimudzirwa.

Nguva yekutumira: Nov-16-2024