1 Muchidimbu

Iyo nzira yekugadzira yekupisa yekuisa tambo yekuisa mbiri yakaomesesa, uye iyo shinda uye laminating maitiro anonoka. Zvigadzirwa zvehafu-zvakapedzwa zvinoyerera mukuita uku zvinopedzwa kuburikidza nekushanda nesimba kwevashandi vazhinji vepamberi-maitiro. Kana marara angoonekwa muchikamu chemitsetse, achaita Kana zvikakonzera kurasikirwa kwakanyanya kwehupfumi, zvinozotungamira mukurasikirwa kwehuwandu hwemabasa apfuura, zvichikonzera kuraswa kukuru.

Munguva yekugadzirwa kwemafuta ekushongedza tambo profiles, maprofiles anowanzo kupepetwa nekuda kwezvikonzero zvakasiyana. Chikonzero chikuru chezvimedu mukuita uku ndiko kuputika kwekupisa-kupisa mutsara notches. Pane zvikonzero zvakawanda zvekupaza kweiyo-yekudzivirira-yekudzivirira strip notch, pano isu tinonyanya kutarisa maitiro ekutsvaga zvikonzero zvehurema hwakaita senge shrink muswe uye stratification inokonzerwa neiyo extrusion maitiro, izvo zvinotungamira kupaza kweiyo notches yealuminium alloy heat insulation profiles panguva yekurukisa uye laminating, uye kugadzirisa dambudziko iri nekuvandudza mold uye nzira.

2 Dambudziko rinoitika

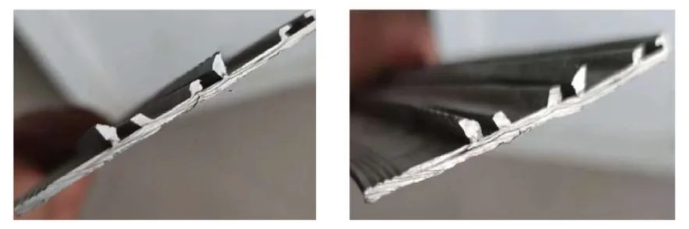

Munguva yekubatanidzwa kwekugadzira maitiro ekupisa kusungirira tambo profiles, batch kupaza kwekushisa-inodzivirira notches kwakangoerekana kwaoneka. Mushure mekutarisa, chiitiko chekuputika chine imwe nzira. Izvo zvese zvinotsemuka pamagumo eimwe modhi, uye kureba kwekutsemuka kwakafanana. Iri mukati mehumwe huwandu (20-40cm kubva kumagumo), uye ichadzokera kune yakajairwa mushure menguva yekutsemuka. Mifananidzo mushure mekutsemuka inoratidzwa muMufananidzo 1 uye Mufananidzo 2.

3 Dambudziko rekutsvaga

1) Chekutanga, sarudza iwo ane dambudziko profiles uye woachengeta pamwe chete, tarisa iyo inopwanya chiitiko chimwe nechimwe, uye tsvaga zvakajairika uye mutsauko mukupwanya. Mushure mekudzokororwa kuteedzera, chiitiko chekuputika chine imwe pateni. Zvose zvinoputika pamagumo emuenzaniso mumwe chete. Chimiro chemuenzaniso wakatsemuka chinhu chakajairika chechinhu chisina mhango, uye kureba kwekuputika kuri mukati meimwe nzvimbo. Mukati (20-40cm kubva kumagumo), ichadzokera kune yakajairika mushure mekuputika kwechinguva.

2) Kubva pakadhi rekutevera rekugadzira reiyi batch yemaprofile, tinogona kuona iyo mold nhamba inoshandiswa mukugadzirwa kwerudzi urwu, panguva yekugadzirwa, saizi yejometri yenotch yeiyi modhi inoedzwa, uye saizi yejometri yetambo yekupisa yekupisa, ma mechanic zvimiro zveprofile uye kuoma kwepasi zvese zviri mukati mehumwe hunonzwisisika.

3) Munguva yekugadzira inoumbwa maitiro, iyo composite process paramita uye mabasa ekugadzira akateedzerwa. Pakanga pasina abnormalities, asi pakanga pachine mitswe pakagadzirwa batch yemaprofile.

4) Mushure mekutarisa kuputsika pakatsemuka, zvimwe zvigadziriso zvinopera zvakawanikwa. Tichifunga kuti chikonzero chechiitiko ichi chinofanira kukonzerwa nekukanganiswa kweextrusion kunokonzerwa nekuita extrusion.

5) Kubva pane chiitiko chiri pamusoro apa, zvinogona kuonekwa kuti chikonzero chekuputika hachisi kuoma kweprofile uye nzira yekubatanidza, asi pakutanga inotarirwa kukonzerwa nekukanganiswa kweextrusion. Kuti uwedzere kuona chikonzero chedambudziko, bvunzo dzinotevera dzakaitwa.

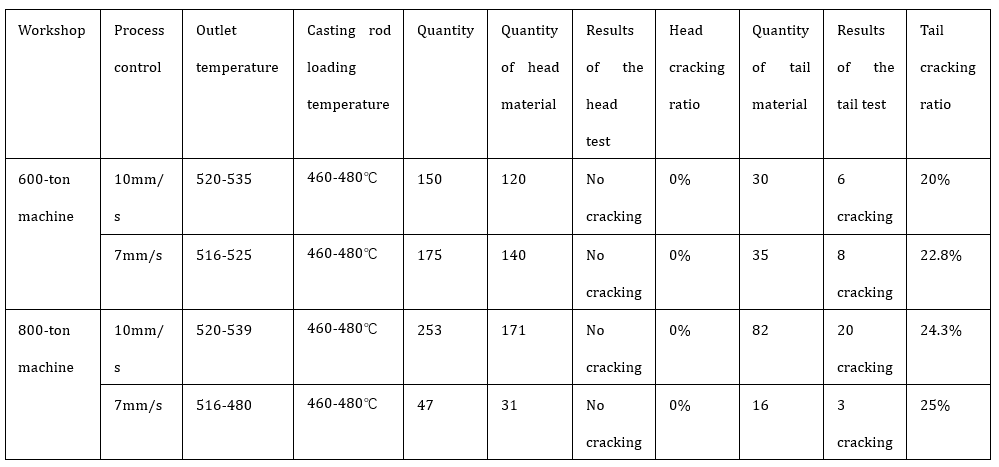

6) Shandisa iyo imwechete seti ye mold kuita bvunzo pamashini akasiyana e tonnage ane akasiyana extrusion kumhanya. Shandisa 600-ton muchina uye 800-ton muchina kuita bvunzo zvakateerana. Maka musoro wezvinhu nemuswe wezvinhu zvakasiyana wozvirongedza mumabhasikiti. Iko kuoma mushure mekukwegura pa10-12HW. Iyo alkaline mvura corrosion nzira yakashandiswa kuyedza chimiro kumusoro uye muswe wezvinhu. Zvakaonekwa kuti muswe wezvinhu waive wakapfava muswe uye stratification phenomena. Chikonzero chekutsemuka kwacho chaive chakatemerwa kukonzerwa nekukwenya muswe uye stratification. Mifananidzo mushure mekugadzirisa alkali inoratidzwa muMifananidzo 2 uye 3. Miedzo yeComposite yakaitwa pane iyi batch yemaprofaili kutarisa chiitiko chekutsemuka. Iyo data yekuyedza inoratidzwa muTafura 1.

Zvifananidzo 2 ne3

7) Kubva pane data iri patafura yepamusoro, inogona kuonekwa kuti hapana kuputika pamusoro wezvinyorwa, uye chikamu chekuputika pamuswe wezvinhu ndicho chikuru. Chikonzero chekupwanya hachina chekuita nehukuru hwemuchina uye nekumhanya kwemuchina. Chiyero chekuputika kwezvinhu zvemuswe ndicho chikuru, icho chinobatana zvakananga nehurefu hwekuona hwemuswe. Mushure mekunge chikamu chinoputika chakanyudzwa mumvura yealkaline uye yakaedzwa, shrink muswe uye stratification ichaonekwa. Kana iyo shrink muswe uye stratification zvikamu zvagurwa, hapazove nekutsemuka.

4 Nzira dzekugadzirisa matambudziko uye matanho ekudzivirira

1) Kuti uderedze kuputika kunokonzerwa nechikonzero ichi, kuvandudza goho, uye kuderedza marara, matanho anotevera anotorwa ekugadzirisa kugadzirwa. Iyi mhinduro inokodzera mamwe mamodheru akafanana akafanana neiyi modhi apo iyo extrusion inofa iri flat die. Iyo shrink muswe uye stratification phenomena inogadzirwa panguva yekugadzirwa kweextrusion inokonzeresa matambudziko emhando sekupaza kwemanoti ekupedzisira panguva yekubatanidza.

2) Paunenge uchigamuchira mold, nyatso kudzora notch size; shandisa chinhu chimwe chete kugadzira mold yakabatana, wedzera makamuri maviri ekushivirira kune mold, kana kuvhura manyepo akapatsanurwa mold kuti uderedze kunaka kwemhando ye shrink muswe uye stratification pane chakapedzwa chigadzirwa.

3) Panguva yekugadzira extrusion, pamusoro pesimbi yealuminium tsvimbo inofanira kunge yakachena uye isina guruva, mafuta uye kumwe kusvibiswa. Iyo extrusion maitiro anofanirwa kutora zvishoma nezvishoma attenuated extrusion mode. Izvi zvinogona kudzikamisa kukurumidza kubuda pakupera kweiyo extrusion uye kuderedza shrink muswe uye stratification.

4) Tembiricha yakaderera uye yakanyanya kumhanya extrusion inoshandiswa panguva yekugadzira extrusion, uye tembiricha yealuminium tsvimbo pamushini inodzorwa pakati pe460-480 ℃. Iyo tembiricha yekuumbwa inodzorwa pa470 ℃ ± 10 ℃, iyo extrusion barrel tembiricha inodzorwa inosvika 420 ℃, uye tembiricha yekubuda kunze inodzorwa pakati pe490-525 ℃. Mushure me extrusion, fan inobatidzwa kuti itonhore. Kureba kwasara kunofanira kuwedzerwa nekupfuura 5mm pane zvamazuva ese.

5) Paunenge uchigadzira rudzi urwu rweprofile, zviri nani kushandisa muchina wakakura kuwedzera simba rekuwedzera, kuvandudza dhigirii resimbi fusion, uye kuve nechokwadi kuti density yezvinhu.

6) Panguva yekugadzirwa kweextrusion, bhakiti remvura alkali rinofanira kugadzirirwa mberi. Mushandi anozoona kubva kumuswe wezvinhu kuti atarise kureba kweiyo shrink muswe uye stratification. Mitsetse mitema pane alkali-etched surface inoratidza kuti shrink muswe uye stratification zvaitika. Mushure mekuwedzera kuona, Kusvikira chikamu chemuchinjikwa chakajeka uye chisina mitsara nhema, tarisa 3-5 aluminium rods kuti uone hurefu hunochinja mushure mokupwanya muswe uye stratification. Kuti udzivise kudonha muswe uye stratification kubva pakuunzwa kune zvigadzirwa zveprofile, 20cm inowedzerwa zvinoenderana neiyo yakareba, tarisa kureba kwemuswe wemuswe we mold set, waona kubva kune dambudziko chikamu uye tanga kucheka muchigadzirwa chakapedzwa. Munguva yekushanda, musoro nemuswe wezvinhu zvinogona kudzika uye kuchekwa zvine simba, asi hurema haufanirwe kuunzwa kune chigadzirwa cheprofile. Inotariswa uye inoongororwa nekuongororwa kwemhando yemuchina. Kana kureba kwemuswe we shrink uye stratification zvichikanganisa goho, bvisa mold nenguva uye cheka mold kusvika zvave zvakajairika isati yatanga kugadzira.

5 Pfupiso

1) Mabheji akati wandei ekupisa-anodzivirira tambo profiles akagadzirwa uchishandisa nzira dziri pamusoro akaedzwa uye hapana yakafanana notch kupaza kwakaitika. Iyo shear maitiro ehunhu hwemaprofiles ese akasvika kune yenyika standard GB / T5237.6-2017 zvinodiwa "Aluminium Alloy Building Profiles No. 6 Chikamu: for Insulating Profiles".

2) Kuti udzivise kuitika kwedambudziko iri, chirongwa chemazuva ese chekuongorora chakagadzirwa kuti chigadzirise dambudziko munguva uye kugadzirisa kudzivirira maprofile ane njodzi kuyerera achipinda mumubatanidzwa uye kuderedza marara mukugadzira.

3) Pamusoro pekudzivirira kuputika kunokonzerwa nekuremara kweextrusion, shrink muswe uye stratification, isu tinofanirwa kugara tichiteerera kune kuputika kwechiitiko chinokonzerwa nezvinhu zvakaita seiyo geometry yenotch, kuoma kwepamusoro uye mechanical zvimiro zvechinyorwa uye maitiro paramita eiyo composite process.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Jun-22-2024