Iyo nzira yekugadzira yealuminium alloy mota mavhiri inonyanya kukamurwa muzvikamu zvinotevera:

1. Kukandira maitiro:

• Gravity casting: Dururira mvura yealuminium alloy muforoma, zadza mold pasi pegiravhiti woitonhodza kuita chimiro. Iyi nzira ine yakaderera michina yekudyara uye iri nyore kushanda, iyo inokodzera diki-diki kugadzirwa. Nekudaro, kugona kwekukanda kwakadzikira, kuenderana kwemhando yechigadzirwa hakuna kunaka, uye kukanganisa kwekukanda senge pores uye shrinkage zvinowanzoitika.

• Low-pressure casting: Mune yakavharwa crucible, iyo aruminiyamu alloy liquid inotsikirirwa muforoma pamhepo yakaderera kuburikidza negasi inert kuti isimbise pasi pekumanikidzwa. Iwo ma castings anogadzirwa neichi maitiro ane dense chimiro, yakanaka yemukati mhando, yakakwirira kugadzirwa zvakanaka, uye akakodzera kugadzirwa kwakawanda, asi mari yemidziyo yakakura, izvo zvinodikanwa zvekuumbwa zvakakwira, uye mutengo wekuumbwa wakakwira zvakare.

• Spin casting: Iri nzira yakagadziridzwa inobva pane yakaderera-kukanda kukanda. Kutanga, iyo isina chinhu yevhiri inoumbwa nekudzika-kukanda kukanda, uye ipapo iyo isina chinhu inogadziriswa pamushini wekutenderera. Chimiro chechikamu chemupendero chinoremara zvishoma nezvishoma uye chinowedzerwa ne mold inotenderera uye kumanikidza. Iyi nzira haingochengetedzi zvakanakira kukanda kwakadzika, asi zvakare inovandudza kusimba uye kurongeka kwevhiri, ukuwo ichideredza uremu hwevhiri.

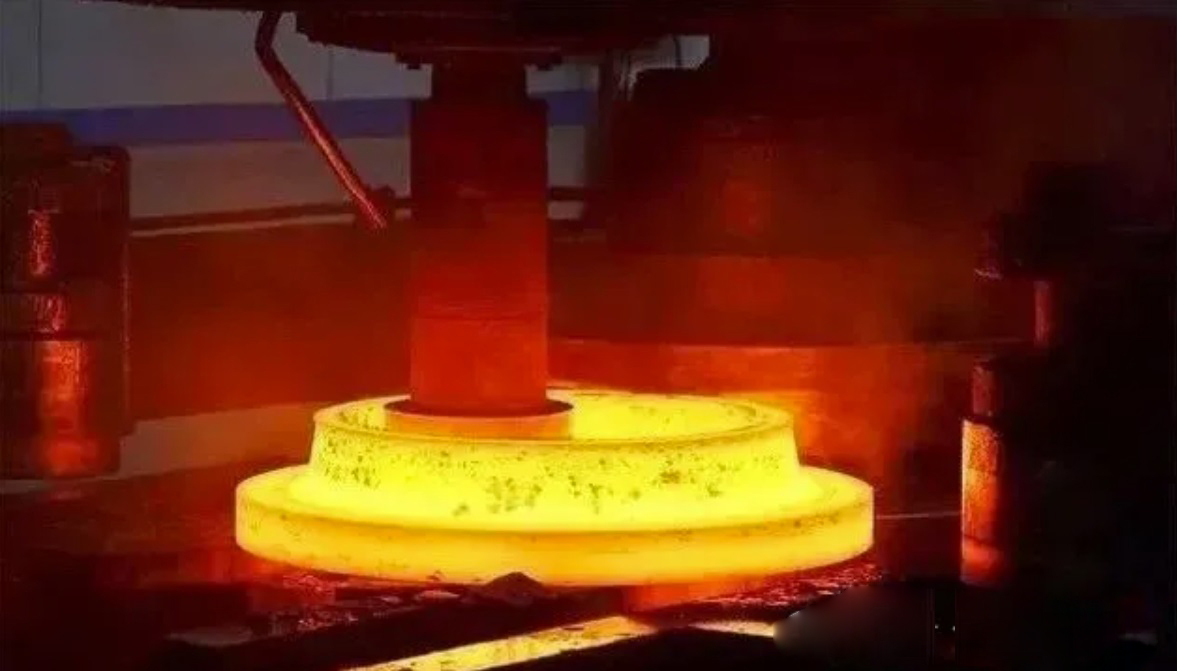

2. Forging process

Mushure mekunge aruminiyamu alloy yadziyirwa kune imwe tembiricha, inoumbwa kuita mold nemuchina wefogi. Forging process inogona kukamurwa mumhando mbiri dzinotevera:

• Kugadzira kwakajairika: Chidimbu chose chealuminium ingot chinogadzirwa zvakananga kuita chimiro chevhiri pasi pekumanikidzwa kukuru. Vhidhi rinogadzirwa neiyi dhizaini rine yakakwira mashandisirwo emidziyo, shoma tsvina, yakanakisa michina zvimiro zvefogi, uye simba rakanaka uye kuoma. Nekudaro, iyo yekudyara yemidziyo yakakura, maitiro acho akaomarara, uye tekinoroji yeanoshanda inodiwa kuve yakakwira.

• Semi-solid forging: Kutanga, iyo aruminiyamu alloy inopisa kusvika kune semi-solid state, panguva iyo iyo aruminiyamu alloy ine imwe fluidity uye forgeability, uye yozogadzirwa. Iyi nzira inogona kuderedza kushandiswa kwesimba mukugadzira maitiro, kunatsiridza kugadzirwa kwakanaka, uye zvakare kunatsiridza kunaka kwevhiri.

3. Welding process

Pepa racho rinokungurutswa kuita humburumbira roiswa weld, uye rinongogadziriswa kana kudzvanywa muvhiri revhiri rine mold, uye ipapo pre-cast vhiri dhisiki rinosungwa kuti ribudise vhiri. The welding nzira inogona Laser welding, erekitironi danda welding, etc. Iyi nzira inoda yakatsaurirwa kugadzirwa mutsetse ine yakakwirira kugadzirwa kunyatsoshanda uye yakakodzera kugadzirwa kwemazhinji, asi chitarisiko chisina kunaka uye matambudziko emhando yeWelding anowanzo kuitika pamapoinzi.

Nguva yekutumira: Nov-27-2024