Chikonzero nei aluminium alloy profiles achishandiswa zvakanyanya muhupenyu nekugadzira ndechekuti munhu wese anonyatsoziva zvakanakira ayo senge yakaderera density, corrosion resistance, yakanakisa magetsi conductivity, non-ferromagnetic properties, formability, uye recyclability.

Indasitiri yekuChina yealuminium profiles yakakura kubva pakatanga, kubva padiki kuenda kuhombe, kudzamara yave nyika huru yekugadzira aluminium profiles, ine inobuda chinzvimbo chekutanga pasirese. Zvisinei, sezvo zvinodiwa nemusika zvezvigadzirwa zvealuminium profiles zvichiramba zvichiwedzera, kugadzirwa kwealuminium profiles kwakagadziridzwa mugwara rekuoma, kurongeka kwepamusoro, uye kugadzirwa kwakakura, izvo zvaunza matambudziko akawanda ekugadzirwa.

Aluminium profiles anonyanya kugadzirwa ne extrusion. Munguva yekugadzira, kunze kwekufunga nezvekuita kweiyo extruder, dhizaini ye mold, kuumbwa kwearuminiyamu tsvimbo, kupisa kupisa uye mamwe maitiro ekuita, iyo yepakati-chikamu dhizaini yeprofile inofanirawo kutariswa. Iyo yakanakisa dhizaini muchinjika-chikamu dhizaini haingogone kudzikisa kuomerwa kwemaitiro kubva kunobva, asi zvakare kuvandudza kunaka uye kushandiswa kwechigadzirwa, kuderedza mutengo uye kupfupisa nguva yekuendesa.

Ichi chinyorwa chinopfupikisa akati wandei anowanzo shandiswa matekiniki mualuminium profile cross-chikamu dhizaini kuburikidza nemakesi chaiwo mukugadzira.

1. Aluminium profile chikamu chekugadzira nheyo

Aluminium profile extrusion inzira yekugadzira iyo inopisa aluminium tsvimbo inoiswa mudhiramu reextrusion, uye kudzvanywa kunoitwa kuburikidza neextruder kuiburitsa kubva mugomba rekufa rechimiro uye saizi yakapihwa, zvichikonzera deformation yepurasitiki kuti iwane chigadzirwa chinodiwa. Sezvo iyo aluminiyamu tsvimbo inobatwa nezvinhu zvakasiyana senge tembiricha, extrusion kumhanya, deformation huwandu, uye mold panguva ye deformation process, kufanana kwekuyerera kwesimbi kunonetsa kudzora, izvo zvinounza mamwe matambudziko pakugadzira mold. Kuti uve nechokwadi chesimba remuumbi uye kudzivisa kuputika, kuputsika, kuputika, nezvimwewo, zvinotevera zvinofanira kudziviswa mukugadzirwa kwechikamu cheprofile: cantilevers hombe, maburi maduku, maburi maduku, porous, asymmetrical, thin-walled, isina kuenzana rusvingo ukobvu, etc. Paunenge uchigadzira, tinofanira kutanga tagutsa kushanda kwayo maererano nekushandiswa, kushongedza, nezvimwewo. Nekuti kana vagadziri vasina ruzivo rweiyo extrusion maitiro uye vasinganzwisise yakakodzera maitirwo emidziyo, uye zvinodiwa zvekugadzira zvakanyanyisa uye zvakasimba, mwero wekufanirwa uchaderedzwa, mutengo uchawedzera, uye chimiro chakakodzera hachizogadzirwa. Naizvozvo, musimboti wealuminium profil chikamu dhizaini ndeye kushandisa iri nyore maitiro sezvinobvira uchigutsa dhizaini yayo inoshanda.

2. Mamwe mazano pamusoro pealuminium profile interface design

2.1 Mhosho muripo

Kuvhara ndechimwe chezvikanganiso zvakajairika mukugadzirwa kweprofile. Zvikonzero zvikuru ndezvizvi:

(1) Maprofayiri ane kuvhurika kwakadzika-chikamu-chikamu kazhinji anovhara kana aburitswa.

(2) Kutambanudza uye kutwasanudza kweprofile kuchawedzera kuvhara.

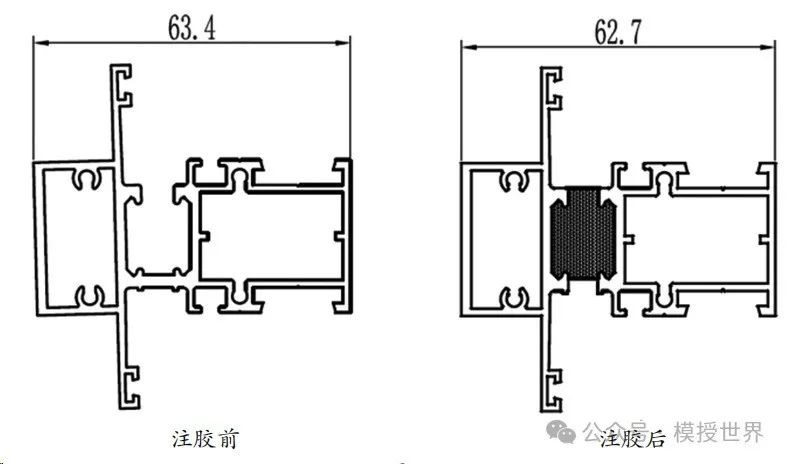

(3) Glue-injected profiles ane zvimwe zvimiro zvichave zvakare nekuvhara nekuda kwekuderera kwecolloid mushure mekunge glue yaiswa.

Kana kuvharwa kwataurwa pamusoro hakusi kwakakomba, kunogona kudziviswa nekudzora chiyero chekuyerera kuburikidza nekugadzira mold; asi kana zvinhu zvakati wandei zvakasimudzwa uye iyo mold dhizaini uye yakabatana maitiro haigone kugadzirisa kuvhara, pre-mubhadharo unogona kupihwa muchinjika-chikamu dhizaini, ndiko kuti, pre-kuvhura.

Kuwanda kwekubhadhara kusati kwavhurwa kunofanira kusarudzwa zvichienderana nemaitiro ayo chaiwo uye chiitiko chekuvhara kwekare. Panguva ino, dhizaini yekuvhura mold yekudhirowa (pre-kuvhura) uye yakapedzwa dhizaini zvakasiyana (Mufananidzo 1).

2.2 Mugovanisa zvikamu zvehukuru-hukuru muzvikamu zvidiki zvakawanda

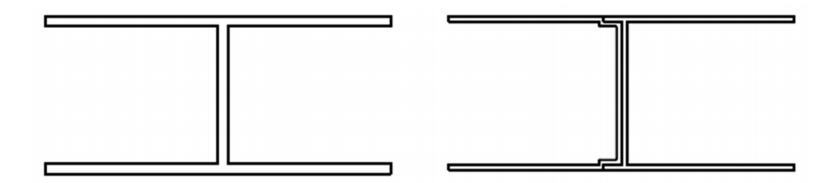

Nekuvandudzwa kwemaprofiles makuru ealuminium, magadzirirwo emuchinjiko wemaprofiles akawanda ari kuwedzera kukura, izvo zvinoreva kuti nhevedzano yemidziyo yakaita semaextruder mahombe, molds mahombe, matanda mahombe ealuminium, nezvimwewo zvinodiwa kuti zvitsigire, uye mari yekugadzira inokwira zvakanyanya. Kune zvimwe zvikamu zvakakura-hukuru zvinogona kuwanikwa nekubatanidza, zvinofanirwa kupatsanurwa kuita zvikamu zvidiki zvinoverengeka panguva yekugadzira. Izvi hazvigone chete kuderedza mari, asiwo kuita kuti zvive nyore kuve nechokwadi cheflatness, curvature, uye yakarurama (Mufananidzo 2).

2.3 Misa mbabvu inosimbisa kuti ivandudze flatness yayo

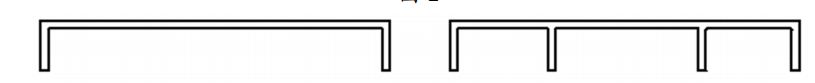

Zvido zveflatness zvinowanzosangana kana uchigadzira zvikamu zveprofile. Diki-span profiles zviri nyore kuve nechokwadi chekudzikama nekuda kwesimba rawo repamusoro. Maprofiles akareba-refu anodonha nekuda kwesimba rawo rinokwevera pasi achangopedza extrusion, uye chikamu chine hukuru hwekukotama kushushikana pakati ndicho chichave chakanyanya concave. Zvakare, nekuti madziro emadziro akareba, zviri nyore kugadzira masaisai, izvo zvinozowedzera kupindirana kwendege. Naizvozvo, hombe-saizi flat plate zvimiro zvinofanirwa kudziviswa muchinjika-chikamu dhizaini. Kana zvichidikanwa, kusimbisa mbabvu inogona kuiswa pakati kuti ivandudze flatness yayo. (Mufananidzo 3)

2.4 Secondary processing

Muchirongwa chekugadzira chimiro, zvimwe zvikamu zvakaoma kupedzisa neextrusion process. Kunyangwe ichigona kuitwa, mari yekugadzirisa uye yekugadzira ichave yakanyanya kukwira. Panguva ino, dzimwe nzira dzekugadzirisa dzinogona kufungwa.

Case 1: Makomba ane dhayamita isingasviki 4mm pachikamu cheprofile achaita kuti mold isakwana musimba, kukuvara nyore, uye kunetsa kugadzirisa. Inokurudzirwa kubvisa maburi maduku uye kushandisa kuchera panzvimbo.

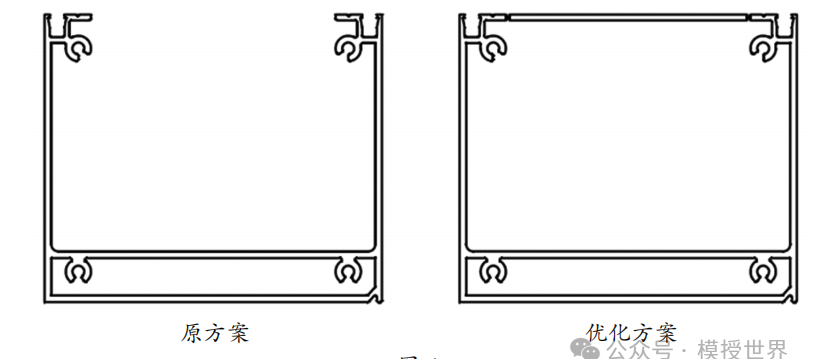

Mhosva yechipiri: Kugadzirwa kweakajairwa neU-shaped grooves hakuna kuoma, asi kana iyo groove yakadzika uye groove yakafara ichidarika 100mm, kana chiyero chehupamhi hwegorofu kusvika kudzika kwegorosi hazvinzwisisike, matambudziko akadai sekusakwana kwesimba rekuumbwa uye kuoma kwekuona kuvhurwa kuchasanganawo panguva yekugadzira. Paunenge uchigadzira chikamu cheprofile, kuvhura kunogona kunzi kwakavharwa, kuitira kuti iyo yepakutanga yakasimba mold ine simba risingakwanisi inogona kushandurwa kuita yakagadzika yakakamurwa mold, uye hapazovi nedambudziko rekuvhura deformation panguva yeextrusion, zvichiita kuti chimiro chive nyore kuchengetedza. Mukuwedzera, mamwe madiki anogona kuitwa pakubatana pakati pemigumo miviri yekuvhura panguva yekugadzira. Semuyenzaniso: isa V-maumbirwo mamakisi, maduku grooves, etc., kuitira kuti vagone kubviswa nyore panguva yekupedzisira machining (Mufananidzo 4).

2.5 Zvakaoma kunze asi zviri nyore mukati

Aluminium profile extrusion molds inogona kukamurwa kuita yakasimba mold uye shunt molds zvichienderana nekuti muchinjiko-chikamu chine mhango. Kugadziriswa kwema molds akasimba kuri nyore, nepo kugadzirisa kwe shunt molds kunosanganisira maitiro akaomarara senge cavities nemisoro yepakati. Naizvozvo, kutarisisa kwakazara kunofanirwa kupihwa kune dhizaini yechikamu cheprofile, ndiko kuti, iyo yekunze contour yechikamu inogona kugadzirwa kuti iwedzere kuomarara, uye grooves, screw holes, nezvimwe zvinofanirwa kuiswa padivi pazvinogoneka, nepo zvemukati zvichifanira kunge zviri nyore sezvinobvira, uye izvo zvinodiwa nekururama hazvigone kuve zvakanyanyisa. Nenzira iyi, zvose kugadzirisa mold uye kugadzirisa zvichange zviri nyore, uye chiyero chegoho chichavandudzwa zvakare.

2.6 Reserved margin

Mushure me extrusion, maprofiles ealuminium ane nzira dzakasiyana dzekurapa dzepamusoro zvinoenderana nezvinodiwa nevatengi. Pakati pavo, anodizing uye electrophoresis nzira dzine zvishoma zvinokanganisa saizi nekuda kweiyo yakaonda firimu layer. Kana iyo nzira yekurapa pamusoro pehupfu yehupfu yakashandiswa, hupfu huchaunganidza nyore mumakona uye grooves, uye hupamhi hwechikamu chimwe chete hunogona kusvika 100 μm. Kana iyi iri nzvimbo yegungano, senge musevedzeri, zvinoreva kuti pane 4 layers yekupfapfaidza coating. Ukobvu hunosvika 400 μm huchaita kuti gungano risagoneke uye kukanganisa kushandiswa.

Uye zvakare, sezvo huwandu hwemaextrusions huchiwedzera uye mold inopfeka, saizi yeprofile slots inova diki uye diki, nepo saizi yeinotsvedza ichiva yakakura uye yakakura, zvichiita kuti gungano rinyanye kuoma. Zvichienderana nezvikonzero zviri pamusoro apa, mapeji akakodzera anofanirwa kuchengetwa zvinoenderana nemamiriro ezvinhu panguva yekugadzira kuti ive nechokwadi chekusangana.

2.7 Kushivirira mucherechedzo

Kudhizaini-chikamu-chikamu, dhizaini yegungano inogadzirwa kutanga uye ipapo iyo profil chigadzirwa dhizaini inogadzirwa. Iyo chaiyo yekudhirowa yegungano haireve kuti iyo profil chigadzirwa dhizaini yakakwana. Vamwe vagadziri vanofuratira kukosha kwedimension uye kushivirira chiratidzo. Iwo akamakwa zvinzvimbo anowanzo zviyero zvinoda kuvimbiswa, senge: nzvimbo yegungano, kuvhura, kudzika kwegorofu, groove upamhi, nezvimwe, uye zviri nyore kuyera nekuongorora. Kune general dimensional tolerances, iyo inoenderana nekurongeka nhanho inogona kusarudzwa zvinoenderana neyakajairwa yenyika. Mamwe mativi akakosha egungano anofanirwa kucherechedzwa nehumwe hunhu hwekushivirira mukudhirowa. Kana kushivirira kwakanyanya, gungano richanyanya kuoma, uye kana kushivirira kuri kudiki, mutengo wekugadzira uchawedzera. Rudzi rwekushivirira rwakakwana runoda kuunganidzwa kwemazuva ese kwemugadziri.

2.8 Detailed kugadzirisa

Details inosarudza kubudirira kana kukundikana, uye zvakafanana kune chimiro chemuchinjiro-chikamu dhizaini. Shanduko diki haigone kuchengetedza mold chete uye kudzora kuyerera kweyero, asi zvakare inovandudza kunaka kwepamusoro uye kuwedzera chiyero chegoho. Imwe yenzira dzinowanzoshandiswa ndeyekutenderera makona. Extruded profiles haigone kuve nemakona akapinza nekuti waya dzakatetepa dzemhangura dzinoshandiswa mukucheka waya dzine madhayamita. Zvisinei, kukurumidza kuyerera pamakona kunononoka, kupesana kwakakura, uye kushungurudzika kwakanyanyisa, pane kazhinji mamiriro ezvinhu apo zviratidzo zveextrusion zviri pachena, ukuru hwakaoma kudzora, uye molds inowanzoita chipping. Naizvozvo, radius inotenderedza inofanira kuwedzerwa zvakanyanya sezvinobvira pasina kukanganisa kushandiswa kwayo.

Kunyange kana iyo yakagadzirwa nemuchina muduku weextrusion, rusvingo rwemadziro rweprofile harufaniri kunge rwuri pasi pe 0.8mm, uye rusvingo rwemadziro echikamu chimwe nechimwe chechikamu hachifaniri kusiyana nekanopfuura ka4. Munguva yekugadzira, mitsara yediagonal kana arc shanduko inogona kushandiswa pane kamwe kamwe shanduko muukobvu hwemadziro kuve nechokwadi chenguva dzose yekuburitsa chimiro uye nyore kugadzirisa mold. Pamusoro pezvo, maprofiles akaonda-akakomberedzwa ane elasticity iri nani, uye ukobvu hwemadziro emamwe magussets, battens, nezvimwe zvinogona kuita 1mm. Kune zvakawanda zvikumbiro zvekugadzirisa tsanangudzo mukugadzira, zvakadai sekugadzirisa makona, kuchinja nzira, kupfupisa cantilevers, kuwedzera mapundu, kuvandudza symmetry, kugadzirisa kushivirira, etc. Muchidimbu, chimiro chechidimbu chechidimbu chinoda kuenderera mberi kwechidimbu uye innovation, uye inonyatsofunga nezvehukama nekugadzira mold, kugadzira, uye maitiro ekugadzira.

3. Mhedziso

Semugadziri, kuti uwane yakanakisa mabhenefiti ehupfumi kubva mukugadzirwa kweprofile, zvese zvinhu zvehupenyu hwese kutenderera kwechigadzirwa zvinofanirwa kutariswa panguva yekugadzira, kusanganisira zvinodiwa nemushandisi, dhizaini, kugadzira, mhando, mutengo, nezvimwewo, edza kuwana budiriro yekuvandudza chigadzirwa kekutanga. Izvi zvinoda kurondwa kwemazuva ese kwekugadzirwa kwechigadzirwa uye kuunganidzwa uye kuunganidzwa kweruzivo rwekutanga-ruoko kuitira kufanofembera mhedzisiro yekugadzira uye kururamisa pamberi.

Nguva yekutumira: Sep-10-2024