1.Introduction

Kurerutsa kurerutsa kwemotokari kwakatanga munyika dzakabudirira uye kwakatanga kutungamirwa nehofori dzechinyakare dzemotokari. Nekuenderera mberi kwekusimudzira, yakawana kukurumidza kukuru. Kubva panguva apo maIndia akatanga kushandisa aruminiyamu alloy kugadzira mota crankshafts kusvika kukutanga kweAudi kugadzirwa kwealuminium mota dzese muna 1999, aruminiyamu alloy yakaona kukura kwakasimba mumashandisirwo emotokari nekuda kwekunaka kwayo senge yakaderera density, yakakwirira chaiyo kusimba uye kuoma, kunaka kwakanaka uye kusimba, kurongeka kwakanyanya, kusimba kwesimba uye kukwirira kwekugadzirisa zvakare. Pakazosvika 2015, chikamu chekushandisa chealuminium alloy mumotokari chakanga chatopfuura 35%.

Kureruka kwemotokari dzeChina kwakatanga asingasviki makore gumi apfuura, uye tekinoroji nedanho rekushandisa zvinosara kumashure kwenyika dzakasimukira dzakaita seGermany, United States, neJapan. Nekudaro, nekuvandudzwa kwemotokari nyowani dzesimba, kureruka kwezvinhu kuri kufambira mberi nekukurumidza. Nekuwedzera kukwira kwemotokari nyowani dzemagetsi, tekinoroji yekuChina yekurerutsa tekinoroji iri kuratidza maitiro ekubata nyika dzakabudirira.

Musika weChina wakareruka zvinhu wakakura. Kune rimwe divi, zvichienzaniswa nenyika dzakasimukira kunze kwenyika, tekinoroji yekuChina yekurerutsa yakatanga kunonoka, uye huremu hwese hwemotokari Curb yakakura. Tichifunga nezve benchmark yezvakareruka zvinhu 'chikamu munyika dzekunze, kuchine nzvimbo yakakwana yebudiriro muChina. Nekune rimwe divi, zvichitungamirwa nemitemo, kukurumidza kusimudzira indasitiri yemotokari yemagetsi yeChina kuchawedzera kudiwa kwezvinhu zvisingaremi uye kukurudzira makambani emotokari kuti aende kunorerutsa.

Kuvandudzwa kwekuburitsa uye kushandiswa kwemafuta zviyero kuri kumanikidza kukwidziridzwa kwemotokari kureruka. China yakanyatsoshandisa mitemo yeChina VI emission muna 2020. Maererano ne "Evaluation Method uye Indicators for Fuel Consumption of Passenger Cars" uye "Energy Saving and New Energy Vehicle Technology Roadmap," iyo 5.0 L/km kushandiswa kwemafuta. Tichifunga nezve nzvimbo shoma yebudiriro yakakura muinjini tekinoroji uye kudzikiswa kwehutsi, kutora matanho kune zviremera zvemotokari zvikamu zvinogona kunyatso kudzikisa kuburitswa kwemotokari uye kushandiswa kwemafuta. Kureruka kwemotokari dzesimba idzva kwave nzira yakakosha yekusimudzira indasitiri.

Muna 2016, China Automotive Engineering Society yakabudisa "Energy Saving uye New Energy Vehicle Technology Roadmap," iyo yakaronga zvinhu zvakadai semashandisirwo emagetsi, rwendo rwekufamba, uye zvigadzirwa zvekugadzira magetsi emagetsi matsva kubva 2020 kusvika 2030. Lightweighting ichava nhungamiro inokosha yekuvandudzwa kwemangwana kwemotokari itsva dzemagetsi. Kureruka kunogona kuwedzera rwendo rwekufamba uye kero "kushushikana kunetseka" mumotokari nyowani dzesimba. Nekuwedzera kuri kuita kudiwa kwekufamba kwakawedzera, kurerutsa kwemotokari kunobva kwave nekukasira, uye kutengeswa kwemotokari dzemagetsi matsva kwakakura zvakanyanya mumakore achangopfuura. Zvinoenderana nezvinodiwa zveiyo mamakisi system uye "Mid-to-Long-Term Development Plan yeIndasitiri Yemotokari," zvinofungidzirwa kuti panosvika 2025, kutengeswa kweChina kwemotokari nyowani dzemagetsi kuchapfuura mamirioni matanhatu, nekukura kwepagore kwekukura kunodarika 38%.

2.Aluminium Alloy Characteristics uye Applications

2.1 Hunhu hweAluminium Alloy

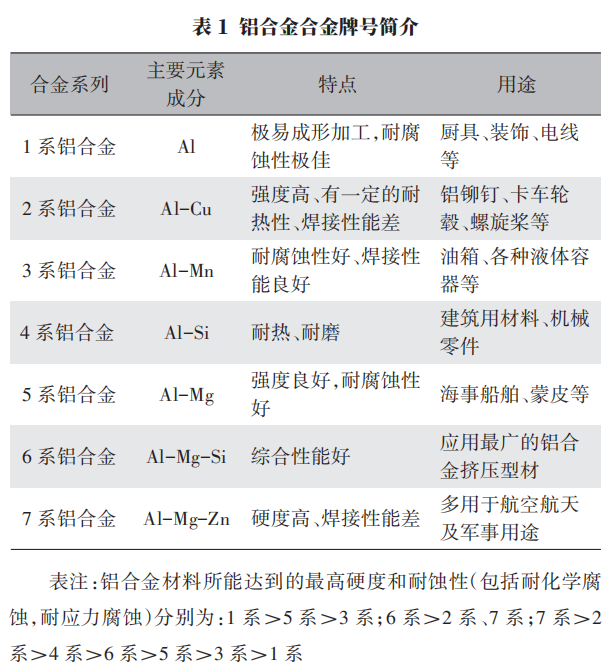

Kuwanda kwealuminium chikamu chimwe muzvitatu chesimbi, zvichiita kuti chireruke. Iyo ine yakakwirira chaiyo simba, yakanaka extrusion kugona, yakasimba corrosion resistance, uye yakakwirira recyclability. Aluminium alloys anoratidzwa nekunyanya kuumbwa ne magnesium, kuratidza kunaka kwekudzivirira kupisa, kunaka kwekugadzira zvinhu, simba rakanaka rekuneta, kusakwanisa kusimbiswa nekurapa kwekupisa, uye kugona kuwedzera simba kuburikidza nekushanda kunotonhora. Iyo 6 yakatevedzana inoratidzwa nekunyanya kuumbwa nemagnesium nesilicon, ine Mg2Si sechikamu chikuru chekusimbisa. Anonyanya kushandiswa alloys muchikamu ichi 6063, 6061, uye 6005A. 5052 aluminium ndiro ndeye AL-Mg yakatevedzana alloy aluminium ndiro, ine magnesium sechinhu chikuru chinosanganisa. Ndiyo inonyanya kushandiswa anti-rust aluminium alloy. Iyi alloy ine simba rakakwirira, simba rakanyanya kuneta, kunaka kwepurasitiki uye kusagadzikana kwemarara, haigoni kusimbiswa nekurapa kwekupisa, ine plastiki yakanaka mune semi-inotonhora basa kuoma, kuderera kwepurasitiki mukushanda kunotonhora kuoma, kunaka kwekudzivirira kwegorosi, uye zvinhu zvakanaka zvekushongedza. Inonyanya kushandiswa kune zvikamu zvakadai semapanhi emativi, zvivharo zvedenga, uye mapaneru emasuo. 6063 aruminiyamu alloy isimbi-inorapa inosimbisa alloy muAl-Mg-Si akatevedzana, ine magnesium uye silicon seyakanyanya kusanganisa zvinhu. Iyo inopisa-inorapa inosimbisa aluminium alloy mbiri ine simba repakati, inonyanya kushandiswa muzvikamu zvechimiro senge makoramu uye mapaneru eparutivi kutakura simba. Nhanganyaya yealuminium alloy mamakisi inoratidzwa muTafura 1.

2.2 Extrusion Yakakosha Kugadzira Nzira yeAluminium Alloy

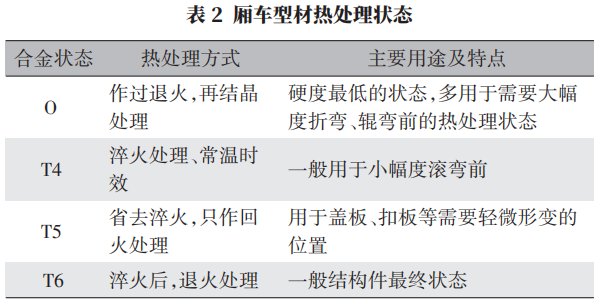

Aluminium alloy extrusion inzira inopisa yekugadzira, uye iyo yese yekugadzira maitiro inosanganisira kugadzira aruminiyamu alloy pasi pematatu-nzira yekumanikidza kushushikana. Iyo yese nzira yekugadzira inogona kutsanangurwa seizvi: a. Aluminium uye mamwe alloys anonyungudutswa uye anokandwa mune inodiwa aluminium alloy billets; b. Mabheti anopisa anoiswa mumidziyo yeextrusion ye extrusion. Pasi pechiito cheiyo cylinder huru, iyo aluminium alloy billet inoumbwa mumaprofiles anodiwa kuburikidza nemhango ye mold; c. Kuti uvandudze michina yealuminium profiles, kurapwa kwemhinduro kunoitwa panguva kana mushure me extrusion, inoteverwa nekuchembera kurapwa. Iyo mechanical properties mushure mekuchembera kurapwa inosiyana zvichienderana nezvinhu zvakasiyana uye kuchembera hurumende. Mamiriro ekupisa ekurapa kwebhokisi-mhando yerori profiles inoratidzwa muTafura 2.

Aluminium alloy extruded zvigadzirwa zvine akawanda mabhenefiti pamusoro pedzimwe nzira dzekugadzira:

a. Munguva yekuwedzeredza, iyo yakawedzera simbi inowana yakasimba uye yakawedzera yunifomu nzira nhatu yekumanikidza kushushikana munzvimbo yedeformation pane kukunguruka nekugadzira, saka inogona kutamba zvizere plastiki yesimbi yakagadziriswa. Inogona kushandiswa kugadzira yakaoma-ku-deform simbi isingagone kugadziriswa nekukungurutswa kana kuforoma uye inogona kushandiswa kugadzira akasiyana-siyana akaoma maburi kana akasimba muchinjiko-chikamu zvikamu.

b. Nekuti iyo geometry yealuminium profiles inogona kuve yakasiyana, zvikamu zvadzo zvine kuomarara kwakanyanya, izvo zvinogona kuvandudza kuomarara kwemuviri wemotokari, kuderedza hunhu hwayo hweNVH, uye kuvandudza hunhu hwemotokari inoshanduka.

c. Zvigadzirwa zvine extrusion kunyatsoita, mushure mekudzima uye kuchembera, zvine yakakwira zvakanyanya longitudinal simba (R, Raz) pane zvigadzirwa zvinogadziriswa nedzimwe nzira.

d. Iyo yepamusoro yezvigadzirwa mushure me extrusion ine yakanaka ruvara uye yakanaka corrosion resistance, kubvisa kudiwa kweimwe anti-corrosion surface treatment.

e. Extrusion processing ine huru inoshanduka, yakaderera tooling uye mold mutengo, uye yakaderera dhizaini shanduko mutengo.

f. Nekuda kwekudzora kwealuminum profile cross-sections, dhigirii rekubatanidzwa kwechikamu rinogona kuwedzerwa, huwandu hwezvikamu hunogona kuderedzwa, uye akasiyana emuchinjiko-chikamu magadzirirwo anogona kuwana chaiyo welding chinzvimbo.

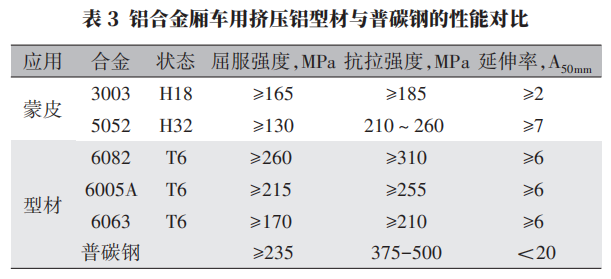

Kuenzanisa kwekuita pakati pearuminiyamu maprofiles akawedzerwa emarori emhando yebhokisi uye plain kabhoni simbi inoratidzwa muTafura 3.

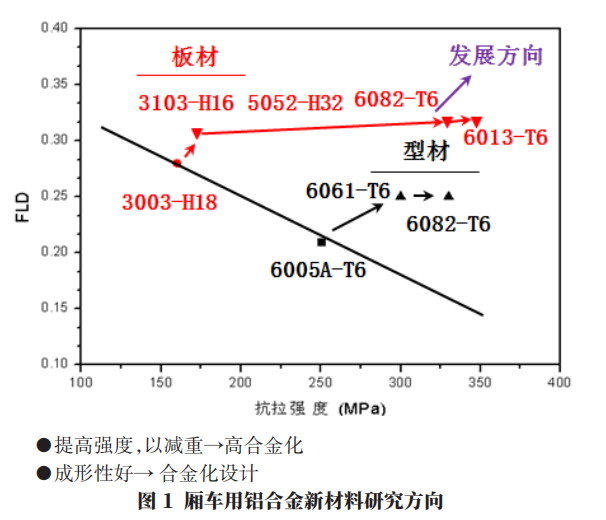

Inotevera Kuvandudza Kutungamira kweAluminium Alloy Profiles yeBhokisi-mhando Marori: Kuenderera mberi nekuvandudza simba reprofile uye kuwedzera extrusion performance. Iyo nzira yekutsvagisa yezvinhu zvitsva zvealuminium alloy profiles yemarori emhando yebhokisi inoratidzwa muMufananidzo 1.

3.Aluminium Alloy Box Truck Structure, Strength Analysis, uye Verification

3.1 Aluminium Alloy Bhokisi Rori Chimiro

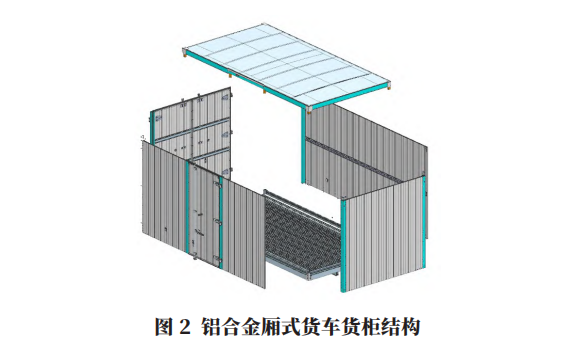

Bhokisi rerori chigadziko chinonyanya kuumbwa nechemberi yepaneru musangano, kuruboshwe uye rworudyi panhizha panhizha musangano, kumashure kwegonhi repanhi remadziro, musangano wepasi, denga reimba, pamwe chete neU-shaped bolts, varindi vepadivi, varindi vekumashure, madhaka anoputika, uye zvimwe zvinhu zvakabatanidzwa kune yechipiri-kirasi chassis. Bhokisi remuviri rinoyambuka matanda, mbiru, matanda eparutivi, uye mapaneru emasuo anogadzirwa nealuminium alloy extruded profiles, nepo pasi nedenga mapaneru akagadzirwa ne5052 aluminium alloy flat plates. Chimiro chealuminium alloy box rori inoratidzwa muMufananidzo 2.

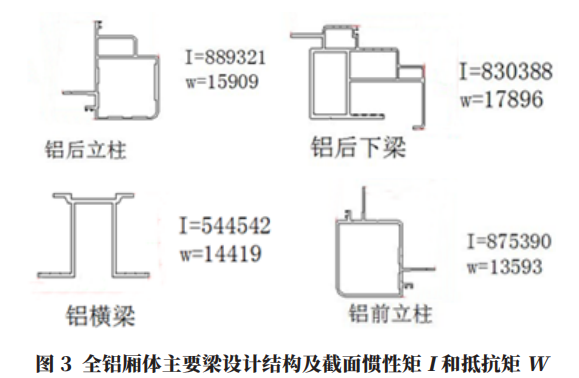

Uchishandisa iyo inopisa extrusion process ye6 akateedzana aruminiyamu alloy inogona kuumba yakaoma hollow cross-sections, dhizaini yealuminium profiles ine yakaoma muchinjiko-zvikamu inogona kuchengetedza zvinhu, kusangana nezvinodiwa zvechigadzirwa kusimba uye kuoma, uye kusangana nezvinodiwa zvekubatana pakati pezvikamu zvakasiyana. Naizvozvo, iyo huru danda dhizaini dhizaini uye zvikamu zvechikamu zve inertia I uye nguva dzekupikisa W zvinoratidzwa mumufananidzo 3.

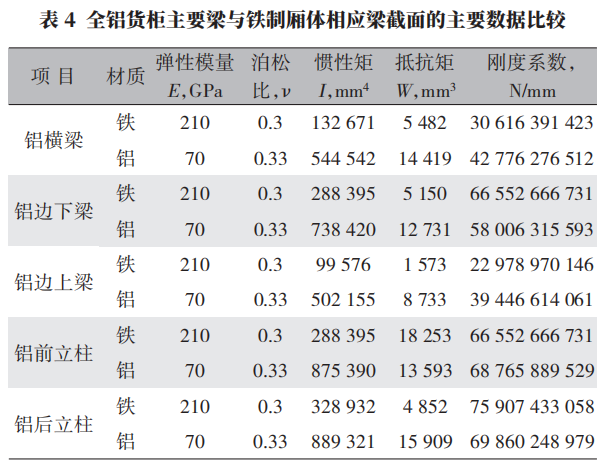

Kuenzanisa kweiyo data huru muTable 4 inoratidza kuti zvikamu zvechikamu zve inertia uye kuramba nguva dzeyakagadzirwa aluminium profiles zviri nani pane inowirirana data yesimbi-yakagadzirwa danda profiles. Iyo yekuomarara coefficient data yakangofanana neiyo inowirirana simbi-yakagadzirwa danda mbiri, uye ese anosangana nezvinodiwa deformation.

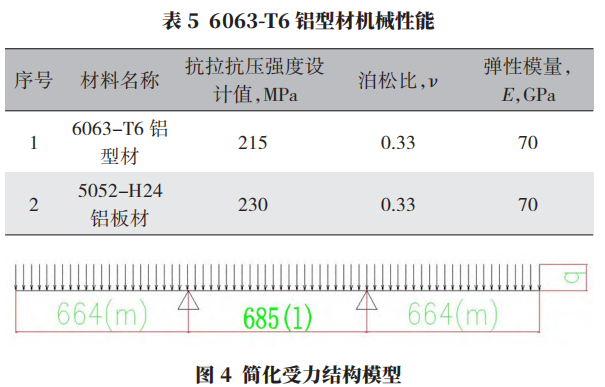

3.2 Maximum Stress Calculation

Kutora kiyi inotakura-inotakura chikamu, iyo crossbeam, sechinhu, iyo yakanyanya kushushikana inoverengerwa. Iyo yakarongerwa mutoro ndeye 1.5 t, uye crossbeam inogadzirwa ne6063-T6 aluminium alloy profile ine mechanical properties sezvinoratidzwa muTebhurari 5. Iyo danda inorerutswa se cantilever chimiro chekuverenga simba, sezvakaratidzwa mumufananidzo 4.

Kutora 344mm span danda, iyo inomanikidza mutoro padanda inoverengerwa seF = 3757 N zvichibva pa4.5t, inova katatu chiyero chakajairwa. q=F/L

uko q ndiko kushushikana kwemukati kwedanda pasi pemutoro, N / mm; F ndiwo mutoro unotakurwa nedanda, rinoverengerwa zvichienderana ne3 nguva yakajairika static load, iyo iri 4.5 t; L ndiko kureba kwedanda, mm.

Naizvozvo, kushushikana kwemukati q ndiko:

Stress calculation formula ndeiyi inotevera:

Iyo yakanyanya nguva ndeye:

Kutora kukosha kwakakwana kwechinguva, M = 274283 N · mm, kunyanya kunetseka σ = M/ (1.05 × w) = 18.78 MPa, uye iyo yakanyanya kunetseka kukosha σ<215 MPa, iyo inosangana nezvinodiwa.

3.3 Kubatanidza Hunhu hweZvikamu Zvakasiyana

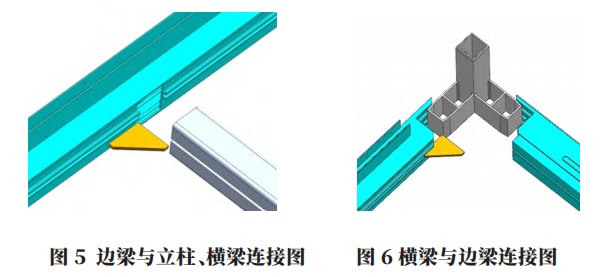

Aluminium alloy ine urombo hwewelding zvivakwa, uye yayo welding point simba ingori 60% ye base base material kusimba. Nekuda kwekuvharwa kwechifukidzo cheAl2O3 pane iyo aluminium alloy pamusoro, nzvimbo yekunyungudika yeAl2O3 yakakwira, nepo kunyungudika kwealuminium kwakaderera. Kana aruminiyamu alloy yakasungwa, iyo Al2O3 iri pamusoro inofanira kukurumidza kuputswa kuita welding. Panguva imwecheteyo, iyo yakasara yeAl2O3 icharamba iri mualuminium alloy solution, inokanganisa chimiro chealuminium alloy uye kuderedza simba realuminium alloy welding point. Naizvozvo, kana uchigadzira ese-aruminiyamu mudziyo, aya maitiro anotariswa zvizere. Welding ndiyo nzira huru yekumisikidza, uye iyo huru-inotakura zvinhu inobatanidzwa nemabhaudhi. Kubatanidza senge riveting uye dovetail chimiro chinoratidzwa muFigure 5 ne6.

Chimiro chikuru chearuminiyamu bhokisi muviri unotora chimiro chine matanda akatwasuka, mbiru dzakamira, matanda eparutivi, uye matanda ekumucheto anopindirana. Pane nzvimbo ina dzekubatanidza pakati pedanda rega rega rakachinjika nembiru yakatwasuka. Iwo mapoinzi ekubatanidza akashongedzerwa ne serrated gaskets kuti mesh ine serrated mupendero weiyo yakachinjika danda, zvinobudirira kudzivirira kutsvedza. Makona masere emakona anonyanya kubatanidzwa nesimbi yepakati pekuisa, yakagadziriswa nemabhoti uye yekuzvivharira rivets, uye yakasimbiswa ne5mm triangular aluminium mahwendefa akaiswa mukati mebhokisi kusimbisa nzvimbo dzekona mukati. Chitarisiko chekunze chebhokisi hachina welding kana pachena mapoinzi ekubatanidza, kuve nechokwadi chekutaridzika kwebhokisi.

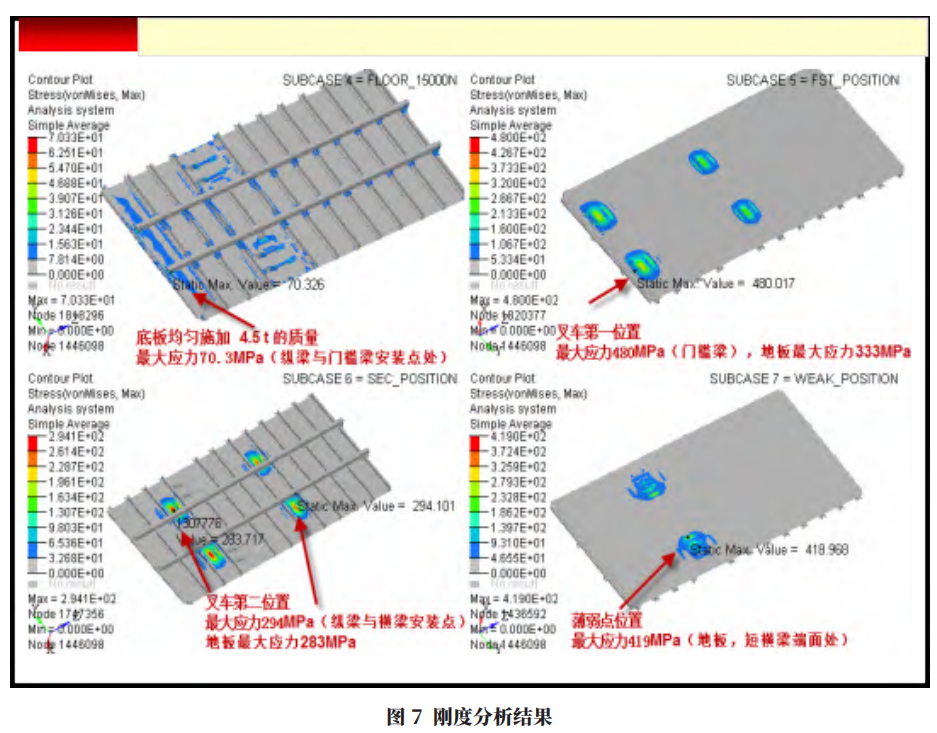

3.4 SE Synchronous Engineering Technology

SE synchronous engineering tekinoroji inoshandiswa kugadzirisa matambudziko anokonzerwa neakakura akaunganidzwa saizi kutsauka kwekufananidza zvikamu zviri mubhokisi muviri uye matambudziko ekutsvaga zvikonzero zvegapu uye kutadza kutadza. Kuburikidza neCAE kuongorora (ona Mufananidzo 7-8), kuongororwa kwekuenzanisa kunoitwa nesimbi-yakagadzirwa nebhokisi miviri kuti iongorore simba rose uye kuoma kwebhokisi rebhokisi, kuwana pfungwa dzisina simba, uye kutora matanho ekugadzirisa nekuvandudza chirongwa chekugadzira zvakanyanya.

4.Lightweighting Effect yeAluminium Alloy Box Truck

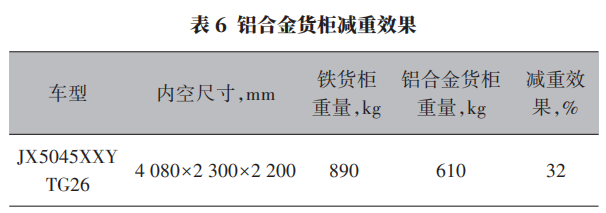

Pamusoro pebhokisi rebhokisi, maaruminiyamu alloys anogona kushandiswa kutsiva simbi kune akasiyana mabhokisi emhando yemidziyo yerori, senge madhaka, varindi vekumashure, varindi vepadivi, machira emagonhi, mahinji emusuwo, uye kumashure epuroni mipendero, kuwana huremu huremu hwe30% kusvika 40% yenzvimbo inotakura zvinhu. Kuderedza uremu kwechinhu chisina chinhu 4080mm×2300mm×2200mm chinotakura zvinhu chinoratidzwa muTable 6. Izvi zvinonyatsogadzirisa matambudziko ehuremu hwakawandisa, kusatevedzera zviziviso, uye njodzi dzekutonga dzechinyakare simbi-yakagadzirwa kutakura migodhi.

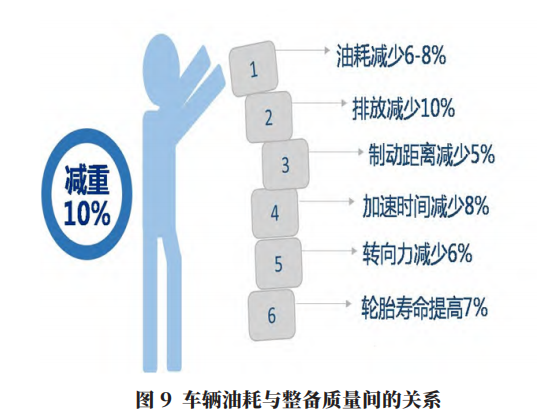

Nekutsiva simbi yechinyakare nealuminium alloys yemidziyo yemotokari, haingogone chete yakanakisa yekurerutsa mhedzisiro inowanikwa, asi inogona zvakare kubatsira mukuchengetedza mafuta, kudzikisira emission, uye nekuvandudza mashandiro emotokari. Parizvino, kune maonero akasiyana-siyana pamusoro pekubatsira kwehuremu hwekuchengetedza mafuta. Mhedzisiro yekutsvaga yeInternational Aluminium Institute inoratidzwa muMufananidzo 9. Yese 10% kuderedzwa kwehuremu hwemotokari kunogona kuderedza kushandiswa kwemafuta ne6% kusvika 8%. Zvichienderana nenhamba dzemumba, kudzikisa huremu hwemotokari yega yega ne100 kg kunogona kuderedza kushandiswa kwemafuta ne0.4 L/100 km. Kubatsira kwekureruka kukuchengetedza mafuta kunobva pane zvakawanikwa kubva kune dzakasiyana nzira dzekutsvagisa, saka pane mutsauko. Nekudaro, kureruka kwemotokari kune chekuita nekuderedza kushandiswa kwemafuta.

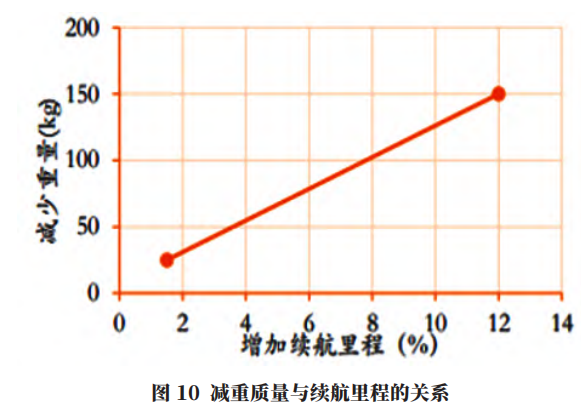

Kune mota dzemagetsi, iyo lightweighting athari inotonyanya kutaurwa. Parizvino, iyo unit simba density yemagetsi emagetsi mabhatiri emagetsi akasiyana zvakanyanya neaya echinyakare emvura mafuta emota. Huremu hwesimba remagetsi (kusanganisira bhatiri) yemotokari dzemagetsi kazhinji inoverengera 20% kusvika 30% yehuremu hwese hwemotokari. Panguva imwe cheteyo, kupaza nepakati pekuita bhodhoro remabhatiri idambudziko repasi rese. Kusati kwave nekubudirira kukuru muhunyanzvi hwekuita bhatiri tekinoroji, kureruka inzira inoshanda yekuvandudza huwandu hwekufamba kwemotokari dzemagetsi. Kune yega yega 100 kg kuderedzwa kwehuremu, huwandu hwekufamba kwemotokari dzemagetsi hunogona kuwedzerwa ne6% kusvika 11% (hukama pakati pekudzikisa uremu uye rwendo rwekufamba runoratidzwa muFigure 10). Parizvino, huwandu hwekufamba kwemotokari dzemagetsi dzakachena haugone kusangana nezvinodiwa nevanhu vazhinji, asi kudzikisa huremu nehumwe huwandu kunogona kuvandudza zvakanyanya rwendo rwekufamba, kurerutsa kushushikana kwehuwandu uye kuvandudza ruzivo rwemushandisi.

5. Mhedziso

Kuwedzera kune ese-aruminiyamu chimiro chealuminium alloy bhokisi rori yakaunzwa muchinyorwa chino, kune marudzi akasiyana-siyana emarori emabhokisi, akadai searuminiyamu yehuchi mapaneru, aluminium buckle plates, aluminium frames + aluminium matehwe, uye iron-aluminium hybrid cargo containers. Ivo vane mabhenefiti ehuremu huremu, simba rakananga, uye kunaka kwekusagadzikana, uye hazvidi pendi ye electrophoretic yekudzivirira ngura, kuderedza kukanganiswa kwezvakatipoteredza kwependi ye electrophoretic. Iyo aruminiyamu alloy bhokisi rori inogadzirisa zvakanyanya matambudziko ehuremu hwakawandisa, kusatevedzera zviziviso, uye njodzi dzekudzora dzechinyakare simbi-yakagadzirwa kutakura migodhi.

Extrusion inzira yakakosha yekugadzirisa yealuminium alloys, uye aluminium profiles ine yakanakisa mechaniki zvivakwa, saka chikamu chekuoma kwezvikamu zvakati wandei. Nekuda kwekusiyana-siyana muchinjiko-chikamu, aruminiyamu alloys anogona kuwana musanganiswa weakawanda echikamu mabasa, zvichiita kuti ive chinhu chakanaka chekureruka kwemotokari. Nekudaro, kushandiswa kwakapararira kwealuminium alloys kunotarisana nematambudziko akadai sekusakwana kwekugadzira kugona kwealuminum alloy cargo compartments, kuumba uye welding nyaya, uye yakakwirira kusimudzira uye kusimudzira mutengo wezvigadzirwa zvitsva. Chikonzero chikuru chiri chekuti aruminiyamu alloy inodhura kupfuura simbi isati yadzokorodza ecology yealuminium alloys isati yakura.

Mukupedzisa, huwandu hwekushandisa kwealuminium alloys mumotokari huchawedzera, uye kushandiswa kwavo kucharamba kuchiwedzera. Mune maitiro azvino ekuchengetedza simba, kudzikisira kuburitsa, uye kusimudzira indasitiri yemotokari yemagetsi, nekunzwisisa kwakadzama kwealuminium alloy zvivakwa uye mhinduro dzinoshanda kumatambudziko ekushandisa kwealuminium alloy, aluminium extrusion zvinhu zvichave zvakanyanya kushandiswa mumotokari lightweighting.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Jan-12-2024