1. Hunhu hwealuminium uye aruminiyamu alloy yakakosha chaiyo extrusion zvinhu

Rudzi urwu rwechigadzirwa rune chimiro chakakosha, mutete madziro ukobvu, light unit uremu, uye zvakanyanya kushivirira zvinodiwa. Zvigadzirwa zvakadaro zvinowanzonzi aluminium alloy precision (kana ultra-precision) profiles (mapombi), uye tekinoroji yekugadzira zvigadzirwa zvakadaro inonzi precision. (kana ultra-precision) extrusion.

Iwo makuru maficha ealuminium alloy chaiyo chaiyo (kana ultra-chaiyo) extrusions ndeiyi:

(1) Kune akawanda marudzi, mabhechi madiki, uye mazhinji acho ndeakakosha-chinangwa extrusion zvinhu, ayo anoshandiswa munenge ese mafambiro ehupenyu uye ese ehupenyu hwevanhu, kusanganisira ese extrusion zvigadzirwa, senge pombi, mbariro, profiles uye waya, zvinosanganisira akasiyana alloy uye nyika. Nekuda kweiyo diki-chikamu-chikamu, mutete madziro ukobvu, huremu huremu, uye mabhechi madiki, kazhinji hazvisi nyore kuronga kugadzirwa.

(2) Maumbirwo akaomarara uye akakosha contours, akanyanya kuumbwa, akafuratira, akafara, ane mapapiro, mazino, ane porous profiles kana mapaipi. Nzvimbo yepamusoro pachiyero cheyuniti yakakura, uye tekinoroji yekugadzira yakaoma.

(3) Wide application, yakakosha kuita uye zvinoshanda zvinodiwa. Kuti usangane nezvinodiwa zvekushandisa zvechigadzirwa, akawanda alloy nyika anosarudzwa, achivhara anenge ese alloys kubva ku1 × × × kusvika 8 × × nhevedzano uye akawanda ematunhu ekurapa, ane yakakwirira tekinoroji zvemukati.

(4) Kutaridzika kwakanaka uye kuonda kwemadziro emadziro, kazhinji asingasviki 0.5mm, mamwe anotosvika anenge 0.1mm, huremu pamita imwe chete magiramu mashoma kusvika kumakumi emagiramu, asi kureba kunogona kusvika akati wandei, kana mazana emamita.

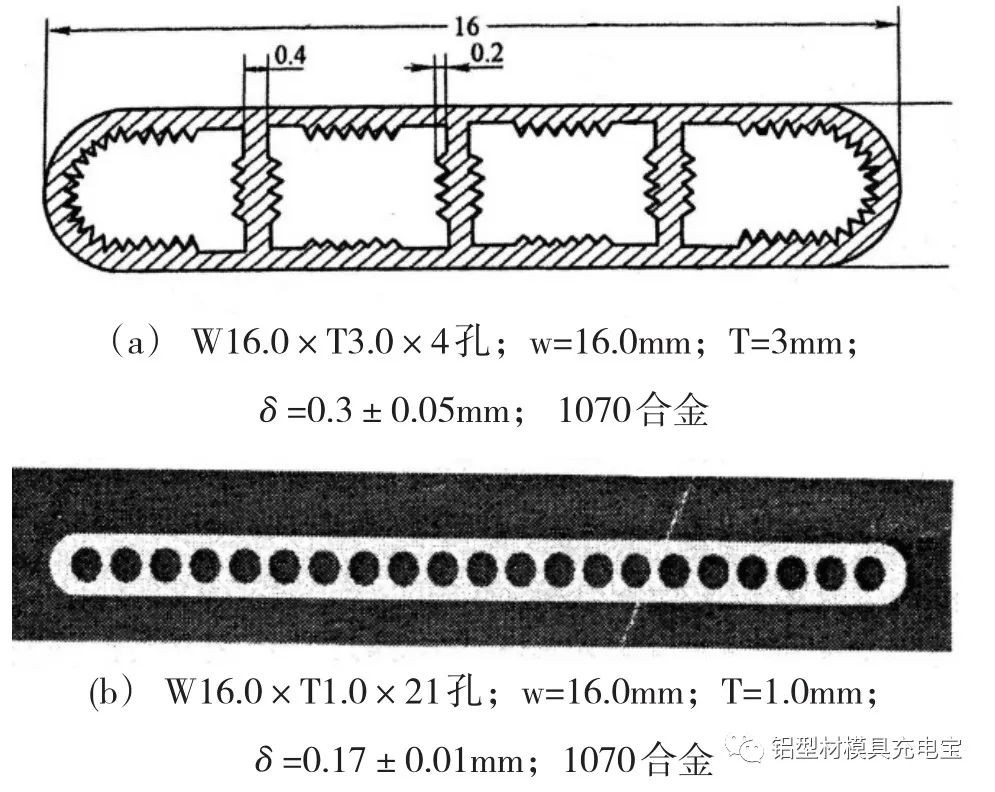

5) Kurongeka kwedimensional uye geometric kushivirira zvinodiwa zvechikamu zvakanyanya kusimba. Kazhinji kutaura, kushivirira kwediki aluminium alloy precision profiles inodarika zvakapetwa kaviri seyakakosha giredhi kushivirira muJIS, GB, uye ASTM zviyero. Iko kushivirira kwemadziro ekushivirira kweakajairika aruminiyamu alloy profiles anodiwa kuve pakati pe ± 0.04mm uye 0.07mm, nepo chikamu chekushivirira kweiyo Ultra-chaiyo aluminium alloy profiles inogona kunge yakakwira se± 0.01mm. Semuenzaniso, uremu hweiyo chaiyo aluminium profiles inoshandiswa kune potentiometer ndeye 30g/m, uye kushivirira kwechikamu chechikamu ± 0.07mm. Iyo muchinjika-chikamu saizi kushivirira kweiyo chaiyo aruminiyamu profiles kune looms ndeye ± 0.04mm, kutsauka kwekona kuri kushoma pane 0.5 °, uye dhigirii rekukotama i0.83 × L. Mumwe muenzaniso ndeyepamusoro-chaiyo yekupedzisira-yakatetepa flat chubhu yemotokari, ine hupamhi hwe20mm, kureba 1.7mm, mudhuri wakakora we0.17±0.01mm, uye 24 maburi, ayo ari akajairika ekupedzisira-chaiyo aluminium alloy profiles.

(6) Iine yakakwirira tekinoroji yemukati uye yakaoma kwazvo kugadzira, uye ine zvakakosha zvinodiwa zve extrusion midziyo, maturusi, mabheti uye maitiro ekugadzira. Mufananidzo 1 muenzaniso wechikamu chemamwe madiki madiki aruminiyamu alloy profiles.

2. Classification yealuminium alloy yakakosha extrusion zvinhu

Precision kana ultra-precision aruminiyamu alloy extrusions anoshandiswa zvakanyanya mumidziyo yemagetsi, midziyo yekukurukurirana uye yekucheka-kumucheto sainzi, kudzivirira kwenyika uye indasitiri yemauto, mashandiro emuchina, midziyo isina simba, aerospace, indasitiri yenyukireya, simba uye simba, ngarava dzepasi pemvura uye ngarava, mota uye maturusi ekufambisa, midziyo yekurapa, hardware maturusi, kuvheneka, kutora mafoto nemagetsi appliance. Kazhinji kutaura, precision kana ultra-precision aluminium alloy extrusions inogona kupatsanurwa muzvikamu zviviri zvinoenderana nechimiro chavo: chikamu chekutanga maprofile ane diki diki. Iyi mhando yeprofile inodaidzwawo kuti ultra-small profile kana mini-shape. Hukuru hwayo hwese hunowanzongoita mamirimita mashoma, ukobvu hwemadziro hushoma huri pasi pe 0.5mm, uye huremu hweyuniti magiramu akati wandei kusvika makumi emagiramu pamita. Nekuda kwehukuru hwavo hudiki, kushivirira kwakasimba kunowanzo kudiwa pavari. Semuenzaniso, kushivirira kwe-cross-sectional dimensions ishoma pane ± 0.05mm. Pamusoro pezvo, izvo zvinodikanwa zvekutwasanuka uye torsion yezvigadzirwa zve extruded zvakare zvakanyanya kuomarara.

Imwe mhando maprofiles asina kudiki-diki muhukuru hwemachinjiro asi anoda akanyanya kuomarara dimensional tolerances, kana maprofiles ane yakaoma muchinjiko-chikamu chimiro uye mutete madziro ukobvu kunyangwe iwo muchinjiko-chikamu saizi yakakura. Mufananidzo 2 unoratidza iyo yakakosha-yakaita chubhu (industrial pure aluminum) yakasimudzwa nekambani yeJapan pane 16.3MN yakachinjika hydraulic press ine yakasarudzika kupatsanurwa kufa kwemotokari yeair-conditioning condenser. Kuoma kwekuumbwa kweextrusion yerudzi urwu rweprofile hakusi pasi peiyo yekare mhando ye-ultra-small profile. Maprofiles akawedzerwa ane saizi yakakura yechikamu uye zvakanyanya kushivirira zvinodiwa hazvidi chete advanced mold dhizaini tekinoroji, asi zvakare inoda yakasimba manejimendi tekinoroji yehurongwa hwese hwekugadzira kubva pachinhu chisina chinhu kusvika chapera chigadzirwa.

Kubva kumavambo ekuma1980, nekuda kwekushandiswa kunoshanda kweConform inoenderera mberi extrusion tekinoroji uye kuvandudza tekinoroji yeindasitiri, kuwedzeredzwa kwemadiki uye ekupedzisira-madiki profiles kwakakura nekukurumidza. Nekudaro, nekuda kwezvikonzero zvakasiyana-siyana senge kushomeka kwemidziyo, zvinodiwa zvemhando yechigadzirwa, uye kufambira mberi mune tekinoroji yeextrusion, kugadzirwa kwemaprofile madiki pamichina yakajairwa extrusion ichiri chikamu chikuru. Mufananidzo 2 unoratidza iwo chaiwo maprofiles e extrusion yeyakajairwa kupatsanurwa inofa. Hupenyu hwemuumbi (kunyanya simba uye kupfeka kupikisa kweshunt bridge uye mold core) uye kuyerera kwezvinhu panguva ye extrusion inova zvinhu zvikuru zvinokanganisa kugadzirwa kwayo. Izvi zvinodaro nekuti kana uchiburitsa chimiro, saizi yemold core idiki uye chimiro chakaomarara, uye simba uye kupfeka kuramba zvinhu zvakakosha zvinokanganisa hupenyu hwemuumbi, hupenyu hwehuhu hunokanganisa zvakananga mutengo wekugadzira. Kune rimwe divi, akawanda echokwadi maprofiles ane madziro matete uye maumbirwo akaomarara, uye kuyerera kwezvinhu panguva yeextrusion process kunobata zvakananga chimiro uye dimensional kurongeka kwemaprofile.

Kuti udzivise iyo oxide firimu nemafuta pamusoro peiyo billet kuti irege kupinda muchigadzirwa uye iva nechokwadi chekuti yunifomu uye yakavimbika kunaka kwechigadzirwa, iyo billet inopisa kusvika kune yakatarwa tembiricha inogona kunyungudutswa isati yabuda (inonzi inopisa peeling), uye wobva wakurumidza kuisa mu extrusion barrel ye extrusion. Panguva imwecheteyo, iyo extruded gasket inofanira kuchengetwa yakachena kudzivirira mafuta uye tsvina kubva pakunamatira kune gasket panguva yekubvisa kudzvinyirira kwakanyanyisa mushure meimwe extrusion uye kuisa gasket mune inotevera extrusion.

Zvinoenderana nechikamu chedimensional kurongeka uye chimiro uye kushivirira kwechinzvimbo, chaiyo chaiyo aluminium alloy extrusion inogona kukamurwa kuita yakakosha chaiyo aluminium alloy profiles uye diki (miniature) Ultra-yakakwirira chaiyo aluminium alloy profiles. Kazhinji, kurongeka kwayo kunodarika chiyero chenyika (senge GB, JIS, ASTM, nezvimwewo) ultra-high precision inonzi special precision aluminium alloy profiles, semuenzaniso, kushivirira kwedimensional kuri pamusoro pe ± 0.1mm, kushivirira kwemadziro kwenzvimbo yakaputsika iri mukati ± 0.05mm ~ ± 0.03mm profiles.

Kana huroyi hwayo huchipfuura zvakapetwa kaviri chiyero chenyika chepamusoro-soro, inodaidzwa kuti diki (miniature) Ultra-yakakwirira chaiyo aruminiyamu alloy profiles, sechimiro chekushivirira kwe± 0.09mm, kushivirira kwemadziro kwe ± 0.03mm ~ ± 0.01mm kwediki (diki) chimiro kana pombi.

3. Tarisiro yekusimudzira yealuminium nealuminium alloy yakakosha chaiyo extrusion zvinhu

Muna 2017, kugadzirwa uye kutengeswa kwealuminium kugadzira zvinhu munyika zvakapfuura 6000kt/a, iyo kugadzirwa uye kutengesa kwealuminium nealuminium alloy extrusion zvinhu zvakapfuura 25000kt/a, zvichiverengera zvinopfuura 40% yehuwandu hwekugadzirwa uye kutengesa kwealuminium. Aluminium extruded yepakati mbariro akaverengera 90%, izvo zvakajairika profiles uye mbariro uye madiki uye epakati hukuru hwekuvaka ehurumende profiles akaverengera kupfuura 80% yebhawa, makuru uye epakati-saizi profiles uye akakosha maprofiles nemabhawa akaverengera chete 15%. Iyo pombi inosvika 8% yearuminiyamu alloy extruded zvinhu, nepo pombi yakaumbwa uye yakakosha pombi account inosvika makumi maviri muzana chete yepombi. Zvinogona kuonekwa kubva pamusoro apa kuti kugadzirwa kukuru uye kutengesa kwealuminium uye aluminium alloy extrusion zvinhu uye inonyanya kushandiswa idiki uye yepakati-saizi yekuvaka yevagari profiles, general profiles nemabhawa nemapombi. Uye maprofayiri akakosha, mabara uye mapaipi anongoverengera anenge 15%, maitiro makuru ezvigadzirwa zvakadaro ndeaya: ane mabasa akakosha kana kuita; Yakatsaurirwa kune chimwe chinangwa; Kuve nehukuru kana hudiki hwekutsanangurwa saizi; Nekunyanya kukwirira kwedimensional kurongeka kana pamusoro pezvinodiwa. Naizvozvo, iyo yakasiyana-siyana yakawanda uye batch ishoma, kudiwa kwekuwedzera akakosha maitiro kana kuwedzera mamwe maturusi akakosha uye maturusi, kugadzirwa kwakaoma uye hunyanzvi hwemukati hwakakwira, mutengo wekugadzira unowedzerwa uye kukosha kwakawedzerwa kunowedzerwa.

Nekufambira mberi kwesainzi uye tekinoroji uye nekuenderera mberi kwekuvandudzwa kwemararamiro evanhu, zvakakwirira nepamusoro zvinodiwa zvakaiswa pamberi pezvinobuda, mhando uye zvakasiyana-siyana zvealuminium uye aruminiyamu alloy extrusion zvigadzirwa, kunyanya mumakore achangopfuura, kubuda kwechigadzirwa chemunhu kwakakurudzira kuvandudzwa kwemaprofiles akakosha uye mapaipi ane hunhu uye mashandisirwo chaiwo.

Ultra-chaiyo maprofiles anoshandiswa zvakanyanya mumidziyo yemagetsi, kutaurirana, post uye nharembozha midziyo, chaiyo muchina, chaiyo zviridzwa, isina simba ikozvino midziyo, aerospace, nyukireya dzepasi pemvura uye ngarava, indasitiri yemotokari uye mamwe minda madiki, akatetepa madziro, chikamu saizi yezvikamu chaizvo. Kazhinji zvinodikanwa zvekushivirira zvakanyanya kuomarara, semuenzaniso, chikamu cheratidziro saizi kushivirira ishoma pane ± 0.10mm, kushivirira kwemadziro kuri kushoma ± 0.05mm. Uye zvakare, iyo flatness, kumonyoroka uye imwe fomu uye chinzvimbo kushivirira kwe extruded zvigadzirwa zvakare yakasimba kwazvo. Uye zvakare, muextrusion process yeakakosha madiki ekupedzisira-chaiyo aluminium alloy profiles, midziyo, mold, maitiro acho akanyanya kusimba zvinodiwa. Nekuda kwekukurumidza kusimukira kweindasitiri yemazuva ano, kudzivirira nyika uye kutsvagisa kwesainzi uye zvimwe zviitiko uye kuvandudzwa kwedhigirii remunhu, huwandu, siyana uye mhando yemadiki ekupedzisira-echokwadi maprofiles ari kuwedzera kukwirira, kunyangwe mumakore achangopfuura, yakagadzira uye kugadzira akawanda emhando yepamusoro madiki e-ultra-precision aruminiyamu alloy profiles, asi zvakadaro haakwanise kuzadzisa zvinodiwa, pakati peiyo musika wekugadzira tekinoroji. yediki-yekupedzisira-chaiyo aluminium alloy profiles uye yepasirese yepamusoro nhanho, isingakwanise kusangana nemusika wepamba uye wekunze kudiwa uye inofanirwa kubatwa kumusoro.

4. Mhedziso

Aluminium nealuminium alloy special precision extrusion (profiles uye pombi) imhando yechimiro chakaomarara, mutete madziro ukobvu, dimensional kushivirira uye chimiro uye chinzvimbo chechokwadi zvinodiwa zvakanyanya kudiwa, yakakwirira tekinoroji yemukati, yakaoma kugadzirwa kwepamusoro, zvinhu zvakanaka, hupfumi hwenyika uye dziviriro yenyika yakakosha zvinhu zvakakosha, zvakasiyana-siyana zvekushandisa, zvinovimbisa kusimudzira zvinhu tarisiro. Kugadzirwa kwechigadzirwa ichi kune zvakakosha zvinodiwa zvebillet, tooling uye extrusion michina uye extrusion process, uye akatevedzana akakosha ehunyanzvi matambudziko anofanirwa kugadziriswa kuitira kuti uwane zvigadzirwa zvakanakisa mumabhechi.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Kubvumbi-07-2024