Anodizing inzira inoshandiswa kugadzira aruminiyamu oxide firimu pamusoro pearuminiyamu kana aruminiyamu alloy zvigadzirwa. Zvinosanganisira kuisa aruminiyamu kana aruminiyamu alloy chigadzirwa seanode mumhinduro ye electrolyte uye kushandisa magetsi kugadzira firimu realuminium oxide. Anodizing inonatsiridza kusimba kwekuora, kupfeka kuramba, uye yekushongedza zvimiro zvealuminium profiles. Munguva yeanodizing maitiro ealuminium profiles, akati wandei akajairika maitiro anogona kuitika. Ngatinyatso nzwisisa zvikonzero zvekuremara kwakaonekwa. Material corrosion, kusvibiswa kwekugezera, kunaya kwechikamu chechipiri chealloy, kana galvanic mhedzisiro zvese zvinogona kutungamirira kune akaremara. Vanotsanangurwa sezvizvi:

1.Acid kana alkali etching

Isati yazodzwa, iyo aruminiyamu inogona kuve yakasvibiswa neasidhi kana alkaline zvinwiwa, kana kukanganiswa nehutsi hweasidhi kana alkaline, zvichikonzera nzvimbo dzakachena pamusoro. Kana ngura yakanyanyisa, makwapa egomba makuru anogona kuumba. Zvakaoma kuziva neziso rakashama kana kuora kunokonzerwa neasidhi kana alkali, asi inogona kusiyaniswa nyore nyore nekucherechedza chikamu chemuchinjikwa chenzvimbo yakasvibiswa pasi pe microscope. Kana pasi pegomba rakatenderera uye pasina intergranular corrosion, inokonzerwa nealkali etching. Kana pasi isiri yenguva uye ichiperekedzwa ne intergranular corrosion, ine makomba akadzika, inokonzerwa ne acid etching. Kuchengetedza kusina kunaka uye kubata mufekitari kunogonawo kutungamirira kune rudzi urwu rwekuora. Utsi hweasidhi kubva kumakemikari ekunatsa kana humwe hutsi hune acidic, pamwe nechlorinated organic degreasers, ndiwo manyuko eacid etching. Yakajairwa alkali etching inokonzerwa nekupararira nekupfapfaidza kwedhaka, simende madota, uye alkaline yekuwachisa zvinwiwa. Kana chikonzero chacho chatemwa, kusimbisa kutungamirirwa kwemaitiro akasiyana-siyana mufekitari kunogona kugadzirisa dambudziko.

2.Atmospheric corrosion

Aluminium profiles yakazarurwa kumhepo ine hunyoro inogona kugadzira mavara machena, ayo anowanzo kuenderana kureba achitevedza mold mitsetse. Atmospheric corrosion kazhinji haina kuomarara seasidhi kana alkali etching uye inogona kubviswa nemichina kana kugeza alkaline. Atmospheric corrosion kazhinji isiri-yenzvimbo uye inowanzoitika pane dzimwe nzvimbo, senge nzvimbo dzetembiricha dzakaderera apo mhute yemvura inonyungudika nyore kana pamusoro. Kana ngura yemuchadenga ichinyanya kuoma, chikamu chemuchinjiko chenzvimbo dzegomba chinoratidzika sehowa hwakapinzwa. Muchiitiko ichi, kushambidzwa kwealkaline hakugone kubvisa mapitting spots uye kunogona kutowedzera iwo. Kana kusvibiswa kwemhepo kwakatemwa, mamiriro ekuchengetedza mufekitari anofanira kuongororwa. Aluminium zvinhu hazvifanirwe kuchengetwa munzvimbo dzine tembiricha yakadzika zvakanyanya kudzivirira mvura mhute condensation. Nzvimbo yekuchengetedza inofanira kunge yakaoma, uye kutonhora kunofanira kunge kwakafanana sezvinobvira.

3.Paper corrosion (nzvimbo dzemvura)

Kana bepa kana makadhibhokisi akaiswa pakati pealuminium zvinhu kana kushandiswa kurongedza, inodzivirira abrasion. Nekudaro, kana bepa rikanyorova, makwapa ekuora anoonekwa pamusoro pealuminium. Kana kadhibhodhi yakakoshwa ichishandiswa, mitsara yenguva dzose yemavara ekuora inoonekwa panzvimbo dzekusangana nebhodhi. Kunyangwe hurema dzimwe nguva hunogona kuoneka zvakananga pane aruminiyamu pamusoro, ivo vanowanzo nyanya kutaurwa mushure mekugeza alkaline uye anodizing. Aya makwapa kazhinji akadzika uye akaoma kubvisa nemuchina kana kugeza alkaline. Pepa (board) corrosion inokonzerwa neion acid, kunyanya SO42- uye Cl-, iyo iripo mupepa. Nokudaro, kushandisa mapepa (bhodhi) pasina chlorides uye sulfates uye kudzivisa kupinda mumvura inzira dzinoshanda dzekudzivirira pepa (bhodhi) kuora.

4.Kunatsa ngura yemvura (inonziwo snowflake corrosion)

Mushure mekugeza alkaline, kupukuta kemikari, kana sulfuric acid pickling, kana mvura yekugeza iine tsvina, inogona kukonzera nyeredzi-yakafanana kana kuti inopenya mavara pamusoro. Kudzika kwecorrosion hakuna kudzika. Rudzi urwu rwekuora runoitika kana mvura yekuchenesa yakasvibiswa zvakanyanya kana kana kuyerera kweyekuyerera kwekupfachuka kuri kuderera. Inofanana nekristaro yakaita sechando muchimiro, saka zita rekuti "snowflake corrosion." Chikonzero ndechekuita pakati pekusachena kwezingi mualuminium uye SO42- uye Cl- mumvura yekuchenesa. Kana kuvharwa kwetangi kwakashata, galvanic mhedzisiro inogona kuwedzera kukanganisa uku. Maererano nekune dzimwe nyika, kana zvinyorwa zveZn mualuminium alloy yakakura kudarika 0.015%, iyo Cl-mumvura yekuchenesa yakakwirira kudarika 15 ppm, rudzi urwu rwekuora runogona kuitika. Kushandisa nitric acid yekunhonga kana kuwedzera 0.1% HNO3 kumvura yekuchenesa kunogona kuibvisa.

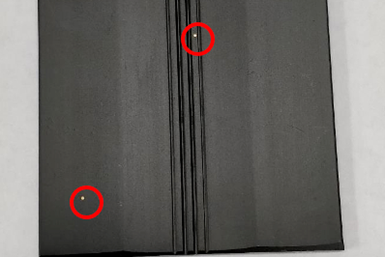

5.Chloride corrosion

Kuvapo kwekashoma kekloridi mu sulfuric acid anodizing bath kunogonawo kutungamirira kugomba gora. Chimiro chechimiro chakadzika nhema nyeredzi-makomba makomba, ayo akanyanya kunyura pamicheto uye makona eiyo workpiece kana mune dzimwe nzvimbo dzine yakakwirira densities ikozvino. Nzvimbo dzegomba hadzina anodized firimu, uye ukobvu hwefirimu munzvimbo dzakasara "dzakajairika" dzakaderera pane zvinotarisirwa kukosha. Munyu wakawandisa mumvura yemupombi ndiyo inokonzeresa Kusvibisa mubhavhu.

6.Galvanic corrosion

Mune tangi ine simba (anodizing kana electrolytic coloring), iyo galvanic mhedzisiro pakati peworkpiece netangi (simbi tangi), kana mhedzisiro yemhepo inorasika mutangi isina-energized (kusuka kana kuvhara), inogona kukonzera kana kuwedzera gomba gomba.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Zvita-15-2023