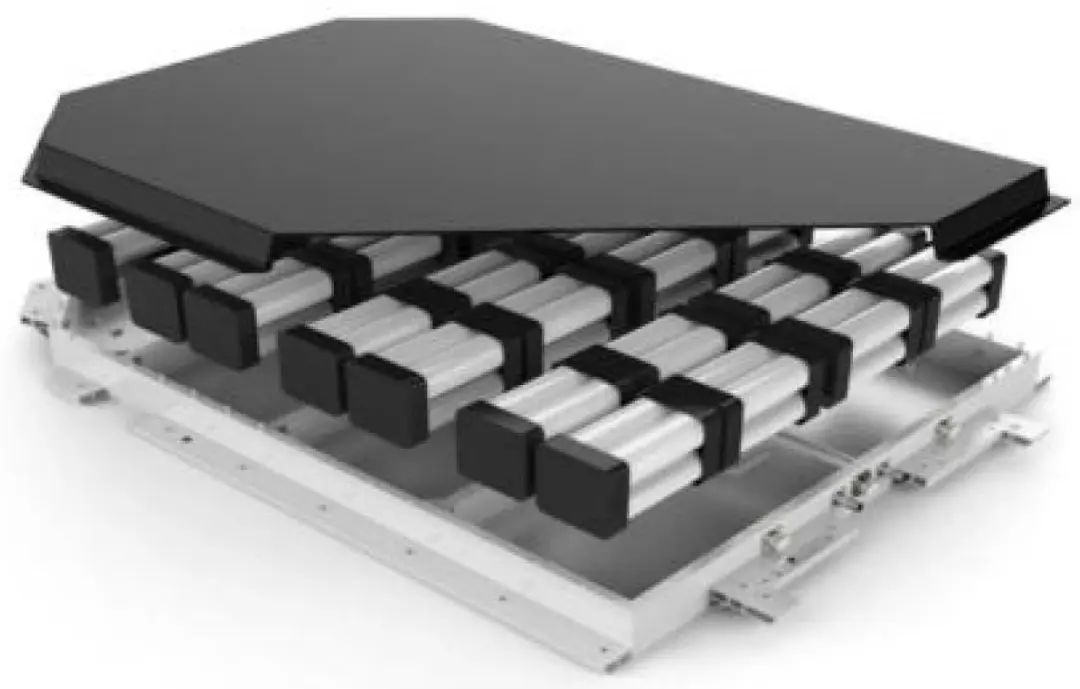

Bhatiri ndiyo yakakosha chikamu chemotokari yemagetsi, uye kuita kwayo kunotaridza zviratidzo zvehunyanzvi zvakaita sehupenyu hwebhatiri, kushandiswa kwesimba, uye hupenyu hwebasa remotokari yemagetsi. Iyo bhatiri tireyi mubhatiri module ndicho chinhu chikuru chinoita mabasa ekutakura, kudzivirira, uye kutonhora. Iyo modular bhatiri pack inorongedzerwa mubhatiri yebhatiri, yakagadzika pane chassis yemotokari kuburikidza nebheteri tray, sezvakaratidzwa muMufananidzo 1. Sezvo yakasungirirwa pasi pemuviri wemotokari uye nzvimbo yekushanda yakaoma, bheti yebheteri inoda kuva nebasa rekudzivirira kukanganisa kwematombo uye puncture kudzivirira bhatiri module kubva pakuparara. Iyo bhatiri tireyi chinhu chakakosha chekuchengetedza dhizaini chikamu chemagetsi emagetsi. Izvi zvinotevera zvinounza maitiro ekugadzira uye mold dhizaini yealuminium alloy bhatiri matireyi emotokari dzemagetsi.

Mufananidzo 1 (Aluminium alloy bhatiri tireyi)

1 Maitiro ekuongorora uye mold dhizaini

1.1 Kukandira kuongorora

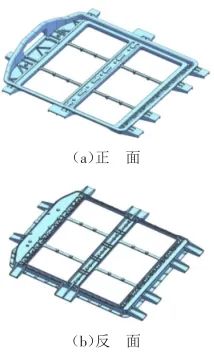

Iyo aruminiyamu alloy bhatiri tireyi yemotokari dzemagetsi inoratidzwa muMufananidzo 2. Izvo zviyero zvese ndeye 1106mm × 1029mm × 136mm, iyo yakakosha madziro ukobvu ndeye 4mm, kukanda mhando inenge 15.5kg, uye kunaka kwekukanda mushure mekugadzirisa kunenge 12.5kg. Nyaya yacho ndeye A356-T6, tensile Strength ≥ 290MPa, goho simba ≥ 225MPa, elongation ≥ 6%, Brinell kuoma ≥ 75~90HBS, inoda kusangana nemhepo yakasimba uye IP67&IP69K zvinodiwa.

Mufananidzo 2 (Aluminium alloy bhatiri tireyi)

1.2 Kuongorora kwemaitiro

Low pressure die casting inzira yakakosha yekukanda pakati pekukandira nekukandira giravhiti. Izvo hazvina chete zvakanakira kushandisa simbi molds kune ese ari maviri, asiwo ine maitiro ekuzadza kwakadzikama. Low pressure die casting ine mabhenefiti ekudzika-kumhanya kuzadza kubva pasi kusvika kumusoro, nyore kudzora kumhanya, kudiki kadhi uye kupfapfaidza kwealuminium yemvura, shoma oxide slag, yakakwira tishu density uye yakakwira michina zvinhu. Pasi pemhepo yakaderera kufa kukanda, iyo aluminium yemvura inozadzwa zvakanaka, uye iyo yekukanda inoomesa uye inopenya pasi pekumanikidzwa, uye kukanda neyakaomesesa chimiro, yakakwira michina zvimiro uye chitarisiko chakanaka chinogona kuwanikwa, icho chakakodzera kugadzira hombe dzakatetepa-madziro castings.

Zvinoenderana nemidziyo yemagetsi inodiwa nekukanda, iyo yekukanda zvinhu ndeye A356, iyo inogona kusangana nezvinodiwa nevatengi mushure mekurapwa kweT6, asi kudururwa kwemvura yechinhu ichi kunowanzoda kudzora kunonzwisisika kwekushisa kwe mold kuti ibudise yakakura uye yakatetepa castings.

1.3 Kudurura system

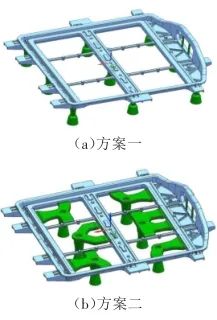

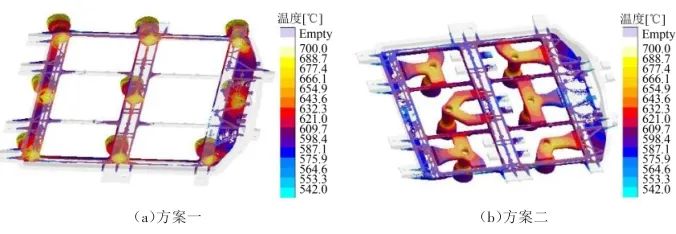

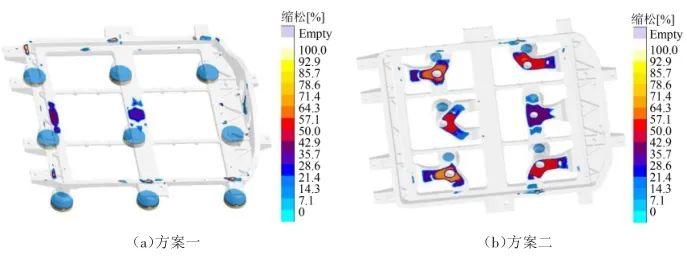

Tichifunga nezvehunhu hweakakura uye akaonda castings, akawanda masuwo anoda kugadzirwa. Panguva imwecheteyo, kuitira kuti uve nechokwadi chekuzadzwa kwemvura yealuminium, nzira dzekuzadza dzinowedzerwa pahwindo, dzinoda kubviswa ne post-processing. Zvirongwa zviviri zvehurongwa hwekudurura zvakagadzirirwa padanho rekutanga, uye chirongwa chega chega chakaenzaniswa. Sezvinoratidzwa muMufananidzo 3, chirongwa 1 chinoronga magedhi 9 uye inowedzera nzira dzekudyisa pahwindo; chirongwa 2 inoronga 6 magedhi anodururira kubva parutivi rwekukanda kuti aumbe. Iyo CAE simulation analysis inoratidzwa muMufananidzo 4 uye Mufananidzo 5. Shandisa migumisiro yekuenzanisa kuti uwedzere kuumbwa kwe mold, edza kudzivisa kukanganisa kwakashata kwekugadzira mold pamusoro pehutano hwekukanda, kuderedza mukana wekukanda kukanganisa, uye kupfupisa kutenderera kwekukura kwekukanda.

Mufananidzo 3 (Kuenzanisa kwemaitiro maviri ekugadzirisa zvirongwa zvekuderedza kudzvinyirira

Mufananidzo 4 (Tembiricha yemunda kuenzanisa panguva yekuzadza)

Mufananidzo 5 (Kuenzanisa kwe shrinkage porosity defects mushure mekusimbiswa)

Mhedzisiro yemhedzisiro yezvirongwa zviviri zviri pamusoro inoratidza kuti iyo aluminium yemvura iri mugomba inokwira ichikwira ichikwira yakada kufanana, inoenderana nedzidziso yekuzadza kwakafanana kwearuminiyamu yemvura yakazara, uye iyo yakateedzerwa shrinkage porosity zvikamu zvekukanda zvinogadziriswa nekusimbisa kutonhora uye dzimwe nzira.

Kubatsira kwezvirongwa zviviri: Kutarisa kubva pakupisa kwealuminium yemvura panguva yekufananidzwa kwekuzadza, kutonhora kwekupedzisira kwekukanda kwakaumbwa nechirongwa 1 kune kufanana kwakakura kudarika kwechirongwa chechipiri, chinokonzera kuzadza kwegomba. Iyo yekukanda inoumbwa nechirongwa 2 haina gedhi residu sechirongwa 1. shrinkage porosity iri nani pane yechirongwa 1.

Zvikanganiso zvezvirongwa zviviri: Nokuti gedhi rakarongeka pakukanda kunofanira kuumbwa muchirongwa 1, pachava negedhi rasara pakukanda, iyo ichawedzera inenge 0.7ka kana ichienzaniswa nekukanda kwepakutanga. kubva kune tembiricha yealuminium yemvura muchirongwa 2 inoteedzerwa kuzadza, tembiricha yealuminium yemvura kumagumo yatove yakaderera, uye simulation iri pasi peyakanaka mamiriro ekushisa kwe mold, saka kuyerera kwealuminiyamu yemvura inogona kunge isina kukwana mune chaiyo mamiriro, uye pachava nedambudziko rekuomerwa mukukanda kuumbwa.

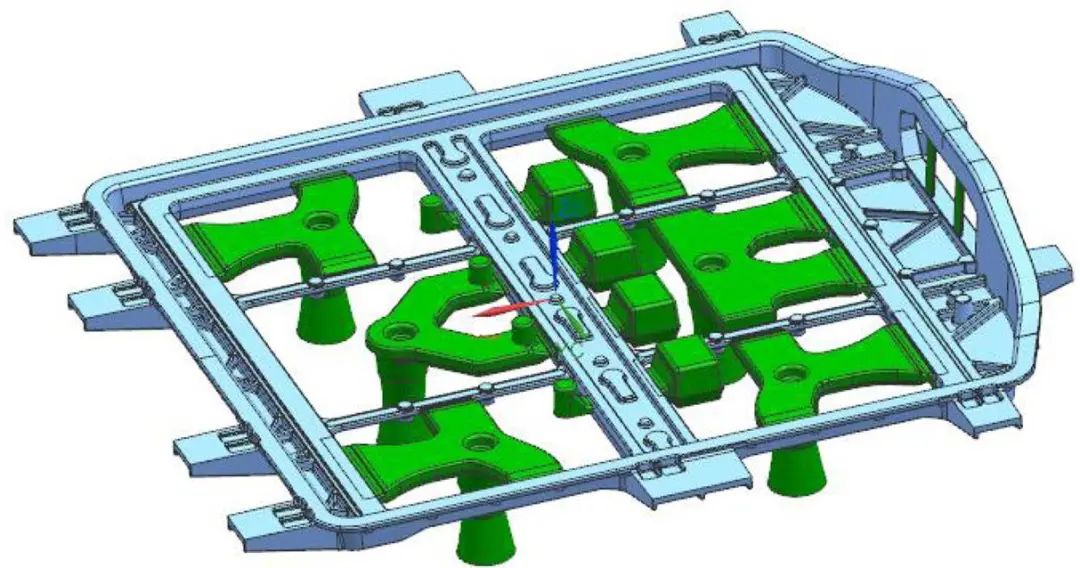

Yakasanganiswa nekuongororwa kwezvinhu zvakasiyana-siyana, chirongwa chechipiri chakasarudzwa senzira yekudira. Tichifunga nezvekukanganisa kwechirongwa che2, iyo yekudurura sisitimu uye yekudziya system inogadziriswa mukugadzira mold. Sezvinoratidzwa muMufananidzo 6, iyo inoputika inokwira inowedzerwa, iyo inobatsira pakuzadza kwealuminium liquid uye inoderedza kana kudzivisa kuitika kwehurema mumakanda akaumbwa.

Mufananidzo 6 (Optimized kudira system)

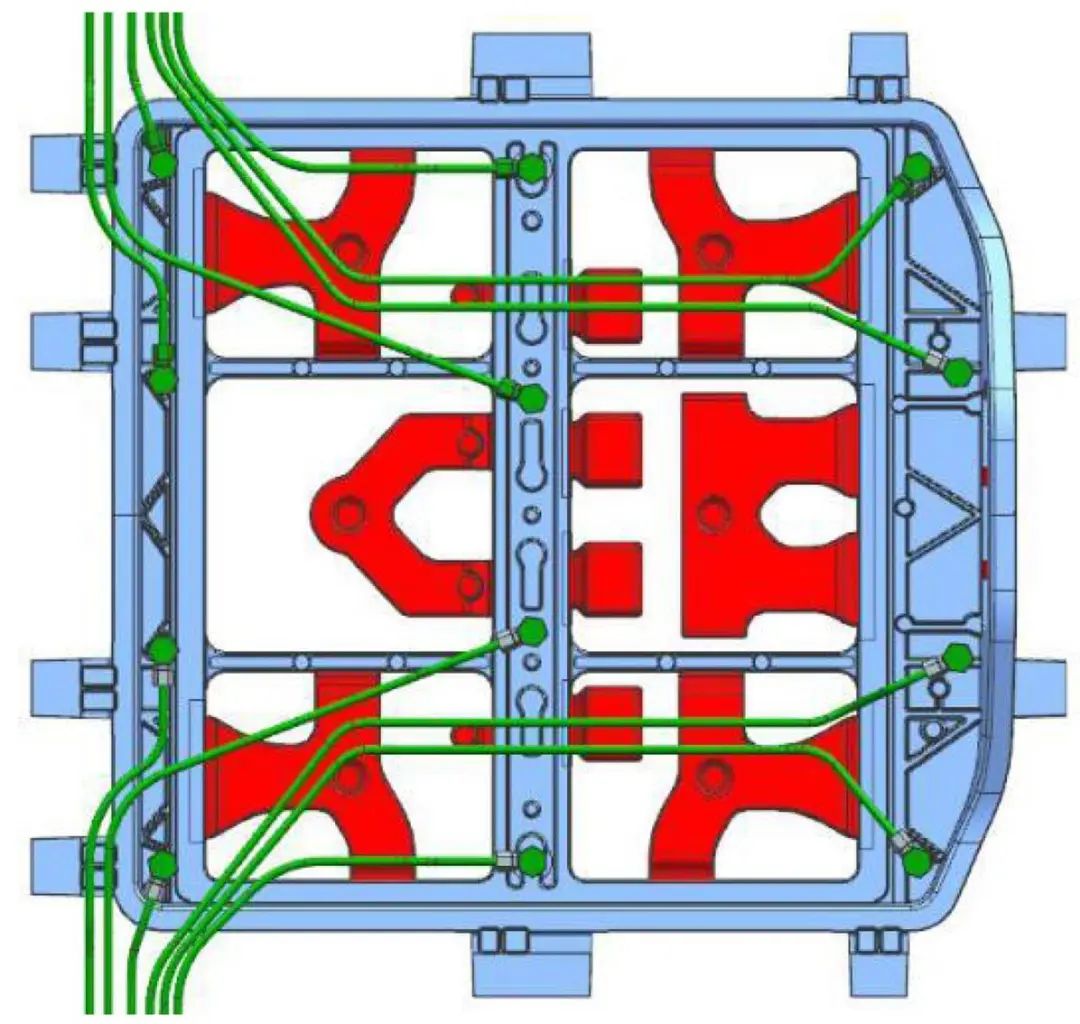

1.4 Kutonhora system

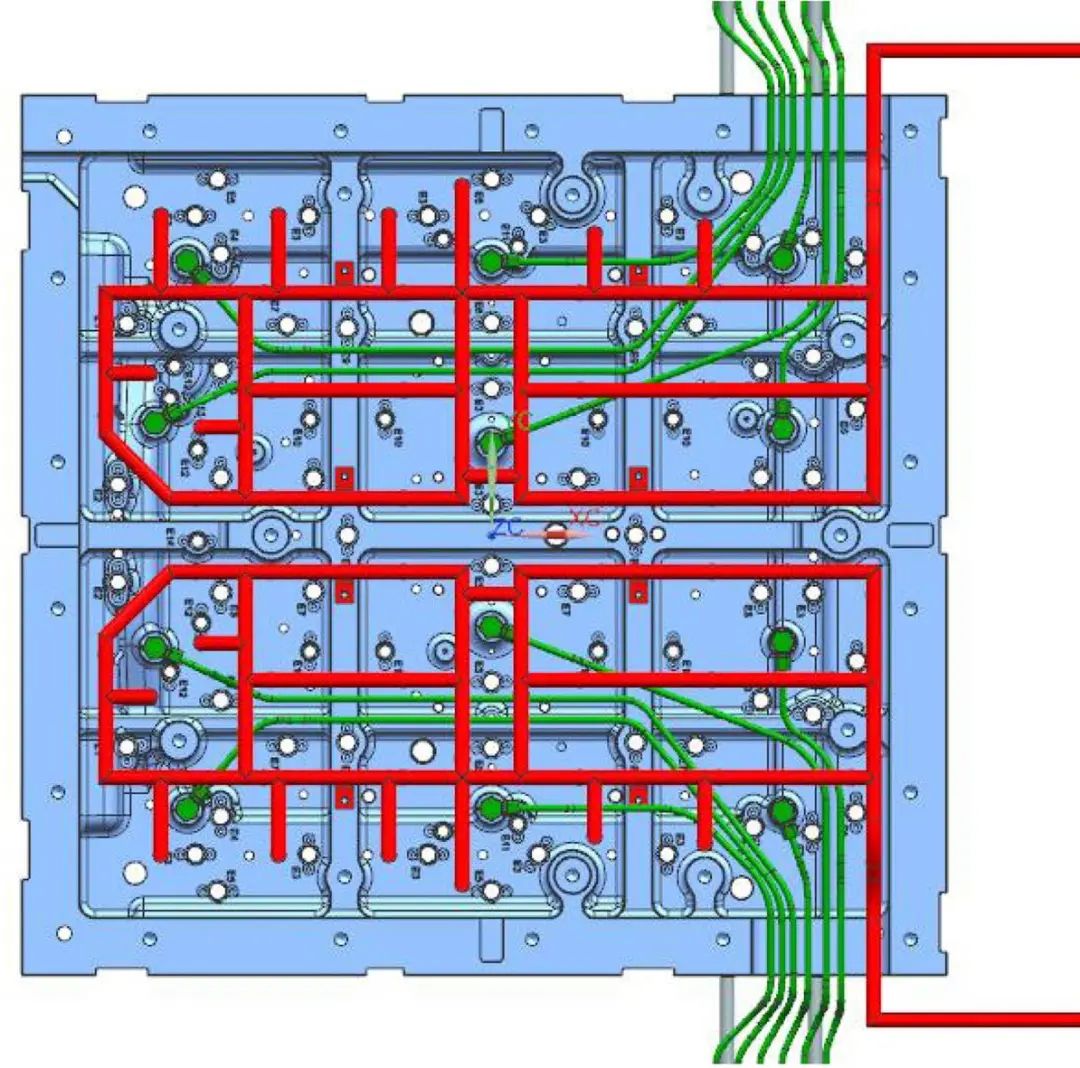

Izvo zvikamu zvinotakura kushushikana uye nzvimbo dzine yakakwira mechanika kuita zvinodiwa zvekukandira zvinoda kunyatsotonhodzwa kana kudyiswa kudzivirira shrinkage porosity kana kupisa kupisa. Iyo yakakosha madziro ukobvu hwekukanda ndeye 4mm, uye kusimba kunozokanganiswa nekupisa kwekupisa kwe mold pachayo. Nokuda kwezvikamu zvaro zvakakosha, chirongwa chekutonhora chinogadziriswa, sezvinoratidzwa mumufananidzo 7. Mushure mokuzadza kwapera, pfuura mvura kuti itonhorere, uye nguva chaiyo yekutonhora inoda kugadziriswa panzvimbo yekudurura kuti ione kuti kutevedzana kwekusimbisa kunoumbwa kubva kure kubva kumagumo egedhi kusvika kumagumo egedhi, uye gedhi uye riser zvakasimbiswa pamagumo kuti zviwane chibereko chekudya. Chikamu chine ukobvu hwemadziro chinotora nzira yekuwedzera kutonhora kwemvura kune inoiswa. Iyi nzira ine mhedzisiro iri nani mune chaiyo yekukanda maitiro uye inogona kudzivirira shrinkage porosity.

Mufananidzo 7 (Kutonhora system)

1.5 Exhaust system

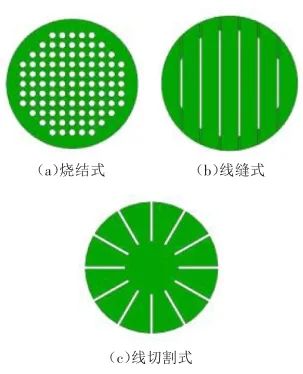

Sezvo mhango yeyakaderera dhizaini yekukanda simbi yakavharwa, haina kunaka kwemhepo kupenya senge molds yejecha, uye haipedzi kuburikidza neanosimuka mune yakajairika giravhiti kukanda, kupera kweiyo yakaderera-kukanda kukanda mhango kuchakanganisa nzira yekuzadza yealuminiyamu yemvura uye kunaka kwekukanda. Iyo yakaderera dhizaini inofa yekukanda mold inogona kupera simba kuburikidza nepakati, exhaust grooves uye exhaust plugs munzvimbo yekuparadzanisa, kusunda tsvimbo nezvimwe.

Iyo yekupedza saizi dhizaini mu exhaust system inofanirwa kuve yakanakira kupera pasina kupfachukira, inonzwisisika exhaust system inogona kudzivirira castings kubva mukukanganisa senge kusakwana kuzadza, yakasununguka nzvimbo, uye yakaderera simba. Iyo yekupedzisira yekuzadza nzvimbo yealuminium yemvura panguva yekudururwa, senge yekuzorora padivi uye inosimuka yekumusoro mold, inoda kuve yakashongedzerwa ne exhaust gasi. Tichifunga nezvekuti aluminium yemvura inoyerera ichipinda mumugero wepureji yekuburitsa mukati meiyo nzira yekudonha kwemhepo, izvo zvinotungamira kune mamiriro ekuti iyo plug yemhepo inoburitswa kana mold yavhurwa, nzira nhatu dzinogamuchirwa mushure mekuedza kwakawanda uye kuvandudzwa: Nzira 1 inoshandisa poda metallurgy sintered air plug, sezvinoratidzwa mumufananidzo 8 (yakashata mutengo); Method 2 inoshandisa seam-type exhaust plug ine gap re 0.1 mm, sezvinoratidzwa muMufananidzo 8 (b), kuipa ndeyekuti musono unovhara nyore nyore mushure mekupfapfaidza pendi; Method 3 inoshandisa wire-cut exhaust plug, gap iri 0.15 ~ 0.2 mm, sezvinoratidzwa mumufananidzo 8 (c). Izvo zvisingabatsiri ndezvishoma kugadzirisa kushanda zvakanaka uye mutengo mukuru wekugadzira. Kusiyana kwakasiyana-siyana kunopedza plugs kunoda kusarudzwa maererano nenzvimbo chaiyo yekukanda. Kazhinji, sintered uye waya-akachekwa vent plugs anoshandiswa kugomba rekukanda, uye mhando yemusono inoshandiswa kune jecha wepakati musoro.

Mufananidzo 8 (3 mhando dze exhaust plugs dzakakodzera kune yakaderera dhizaini kufa kukandira)

1.6 Heating system

Iyo yekukanda yakakura muhukuru uye yakatetepa mukukora kwemadziro. Mukuongorora kuyerera kwe mold, kuyerera kweiyo liquid aluminium pakupera kwekuzadza haina kukwana. Chikonzero ndechekuti iyo aluminiyamu yemvura yakarebesa kuyerera, tembiricha inodonha, uye iyo aluminium yemvura inoomesa mberi uye inorasikirwa nekuyerera kwayo, kutonhora kuvharika kana kusakwana kudurura kunoitika, inosimuka yekumusoro kufa haizokwanise kuita mhedzisiro yekudyisa. Zvichienderana nezvinetso izvi, pasina kushandura kukora kwemadziro uye chimiro chekukandira, wedzera tembiricha yealuminium yemvura uye tembiricha yekuumbwa, kunatsiridza kuyerera kwealuminium yemvura, uye kugadzirisa dambudziko rekuvhara kutonhora kana kusakwana kudurura. Nekudaro, yakawandisa yealuminium tembiricha yemvura uye mold tembiricha inoburitsa mitsva yekupisa kana shrinkage porosity, zvichikonzera kuwanda kwepinholes ndege mushure mekukanda kugadzirisa. Naizvozvo, zvinodikanwa kusarudza yakakodzera mvura aluminium tembiricha uye tembiricha yakakodzera mold. Zvinoenderana neruzivo, tembiricha yearuminiyamu yemvura inodzorwa paanenge 720 ℃, uye tembiricha yekuumbwa inodzorwa pa320 ~ 350 ℃.

Mukuona kwehuwandu hukuru, hutete hwemadziro emadziro uye hurefu hwakaderera hwekukanda, hurongwa hwekupisa hunoiswa panzvimbo yepamusoro ye mold. Sezvinoratidzwa muMufananidzo 9, kutungamira kwemurazvo kunotarisana nechepasi uye nerutivi rwe mold kuti upise ndege yepasi uye rutivi rwekukanda. Zvinoenderana nemamiriro ekudururira pasaiti, gadzirisa nguva yekudziya uye murazvo, dzora tembiricha yekumusoro mold chikamu pa320 ~ 350 ℃, simbisa kuyerera kwealuminiyamu yemvura mukati mehumwe hunoenderana, uye ita kuti iyo aruminiyamu yemvura izadze mhango uye riser. Mukushandisa chaiko, iyo yekudziya system inogona kunyatso simbisa fluidity yemvura aluminium.

Mufananidzo 9 (Heating system)

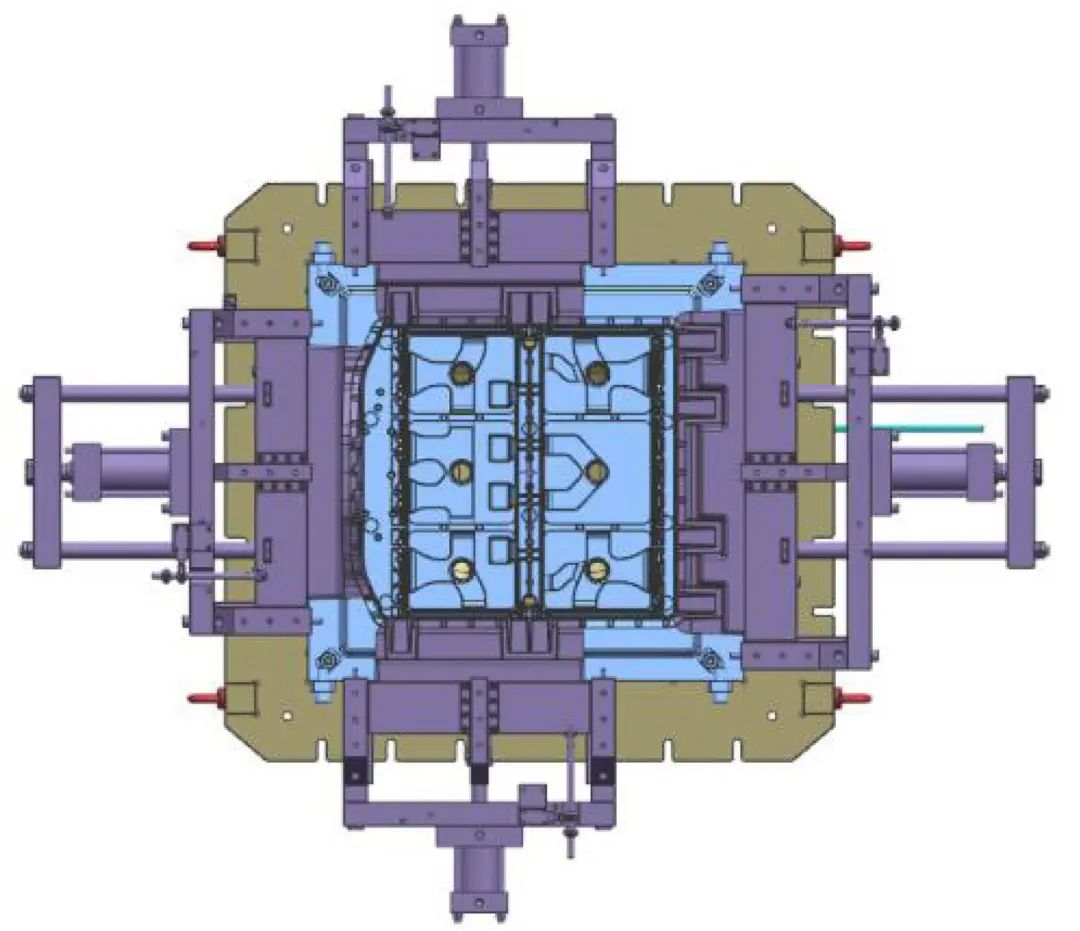

2. Mold chimiro uye nheyo yekushanda

Zvinoenderana neiyo low pressure die casting process, yakasanganiswa nehunhu hwekukanda uye chimiro chemidziyo, kuitira kuti ive nechokwadi chekuti iyo yakaumbwa yekukanda inogara muhuvhu hwepamusoro, kumberi, kumashure, kuruboshwe uye kurudyi-pakati-kudhonza zvimiro zvakagadzirirwa pane yepamusoro mold. Mushure mekunge kuumbwa kwagadzirwa uye kusimba, molds dzepamusoro nedzezasi dzinotanga kuvhurwa, uyezve dhonza musimboti munzira 4, uye pakupedzisira ndiro yepamusoro yechiumbwa chepamusoro inosundira kunze kwakaumbwa kukanda. Iyo mold chimiro inoratidzwa muMufananidzo 10.

Mufananidzo 10 (Mold structure)

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: May-11-2023