Nhanganyaya

Nekuvandudzwa kweindasitiri yemotokari, musika wealuminium alloy impact matanda uri kukurawo nekukurumidza, kunyangwe uchiri mudiki muhukuru hwese. Zvinoenderana nekufanotaura neMotomotive Lightweight Technology Innovation Alliance yeChinese aluminium alloy impact beam market, panosvika 2025, kudiwa kwemusika kunofungidzirwa kunge kunosvika zviuru zana nemakumi mana ezviuru zvematani, nehukuru hwemusika hunotarisirwa kusvika mabhiriyoni mana nemazana masere emadhora. Pakazosvika 2030, kudiwa kwemusika kunofungidzirwa kunge kungangoita mazana maviri nemakumi maviri ezviuru zvematani, nehukuru hunofungidzirwa hwemusika hwe7.7 bhiriyoni RMB, uye huwandu hwepagore hwekukura hunosvika gumi nenhatu%. Iyo yekusimudzira maitiro ekureruka uye kukurumidza kukurumidza kwepakati-kusvika-yepamusoro-yekupedzisira modhi yemotokari zvinhu zvakakosha zvekutyaira zvekusimudzira aluminium alloy kukanganisa matanda muChina. Iwo musika tarisiro yemotokari inokanganisa danda mabhokisi ari kuvimbisa.

Sezvo mutengo uchidzikira uye tekinoroji ichifambira mberi, aluminium alloy kumberi kunokanganisa matanda uye mabhokisi ekuparara ari kuwedzera zvishoma nezvishoma. Parizvino, anoshandiswa pakati-kusvika-yepamusoro-yekupedzisira mota modhi seAudi A3, Audi A4L, BMW 3 akatevedzana, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, uye Buick LaCrosse.

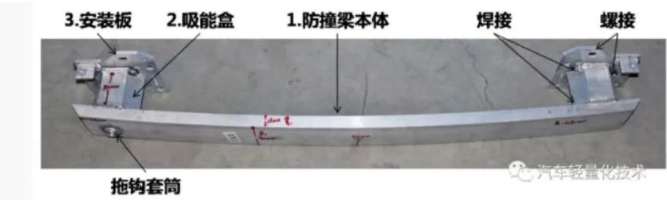

Aluminium alloy impact matanda anonyanya kuumbwa ne impact crossbeams, crash boxes, mounting baseplates, and towing hook sleeves, sezvinoratidzwa mumufananidzo 1.

Mufananidzo 1: Aluminium Alloy Impact Beam Assembly

Bhokisi rekupunzika ibhokisi resimbi riri pakati pesimbi yekukanganisa uye maviri akareba matanda emotokari, anonyanya kushanda semudziyo unotora simba. Simba iri rinoreva simba rekukanganisa. Kana mota ikasangana nekudhumhana, danda rekukanganisa rine imwe nhanho yekugona kutora simba. Nekudaro, kana simba racho rakapfuura kugona kweiyo danda rekukanganisa, rinoendesa simba kubhokisi rekuparara. Bhokisi rekupunzika rinotora ese simba rekuita uye rinozvishandura pacharo, kuve nechokwadi chekuti matanda erebeti anoramba asina kukuvara.

1 Product Zvinodiwa

1.1 Zviyero zvinofanirwa kutevedzera kudhirowa kushivirira zvinodiwa, sezvakaratidzwa mumufananidzo 2.

1.3 Mechanical Performance Zvinodiwa:

Tensile Simba: ≥215 MPa

Goho Simba: ≥205 MPa

Elongation A50: ≥10%

1.4 Crash Bhokisi Kupwanya Kuita:

Padivi pemotokari ye-X-axis, uchishandisa nzvimbo yekudhumhana yakakura kupfuura chikamu chemuchinjiko, takura nekumhanya kwe100 mm/min kusvika pakupwanya, nekutsikirira huwandu hwe70%. Kureba kwekutanga kweprofile ndeye 300 mm. Pakusangana kwembabvu inosimbisa uye madziro ekunze, kuputika kunofanira kunge kuri pasi pe15 mm kuti kuonekwe kunogamuchirwa. Izvo zvinofanirwa kuve nechokwadi kuti iyo inotenderwa kutsemuka haikanganisi iyo profiles yekupwanya simba-inotora simba, uye hapafanirwe kuve nekutsemuka kwakakosha kune dzimwe nzvimbo mushure mekupwanya.

2 Nzira Yekuvandudza

Kuti panguva imwe chete isangane nezvinodiwa zvemakanika kuita uye kupwanya kuita, nzira yekuvandudza ndeiyi inotevera:

Shandisa 6063B tsvimbo ine yekutanga alloy kuumbwa kweSi 0.38-0.41% uye Mg 0.53-0.60%.

Ita mhepo inodzima uye kuchembera kwekugadzira kuti uwane iyo T6 mamiriro.

Shandisa mhute + kudzima mhepo uye itisa kurapwa-kukwegura kuti uwane mamiriro eT7.

3 Pilot Production

3.1 Extrusion Conditions

Kugadzirwa kunoitwa pane 2000T extrusion press ine extrusion ratio ye 36. Nyaya inoshandiswa inonzi homogenized aluminium rod 6063B. Kupisa kwekushisa kwemudonzvo wealuminium ndeaya anotevera: IV zone 450-III zone 470-II zone 490-1 zone 500. Iyo huru cylinder's breakthrough pressure inenge yakapoteredza 210 bar, ine stable extrusion phase ine extrusion pressure pedyo ne180 bar. Iyo extrusion shaft kumhanya ndeye 2.5 mm / s, uye iyo profil extrusion kumhanya ndeye 5.3 m/min. Tembiricha paextrusion outlet i500-540°C. Kudzima kunoitwa pachishandiswa kutonhora kwemhepo nekuruboshwe feni simba pa100%, simba repakati feni pa100%, uye kurudyi fan simba pa50%. Avhareji yekutonhora mukati menzvimbo yekudzima inosvika 300-350 ° C / min, uye tembiricha mushure mekubuda munzvimbo yekudzima i60-180 ° C. Kune mhute + mhepo inodzima, avhareji yekutonhora mukati menzvimbo yekudziya inosvika 430-480 ° C/min, uye tembiricha mushure mekubuda munzvimbo yekudzima i50-70 ° C. Iyo profil hairatidzi kukotama kwakakosha.

3.2 Kuchembera

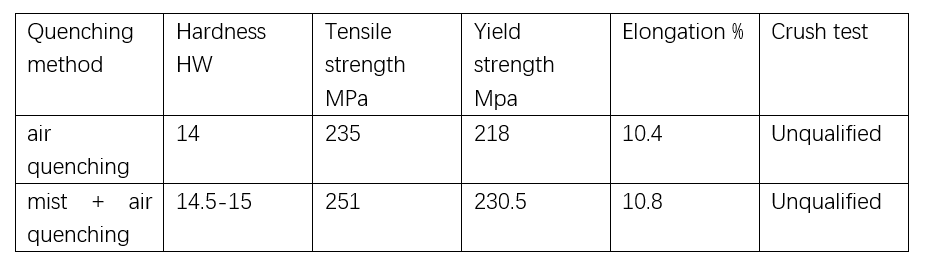

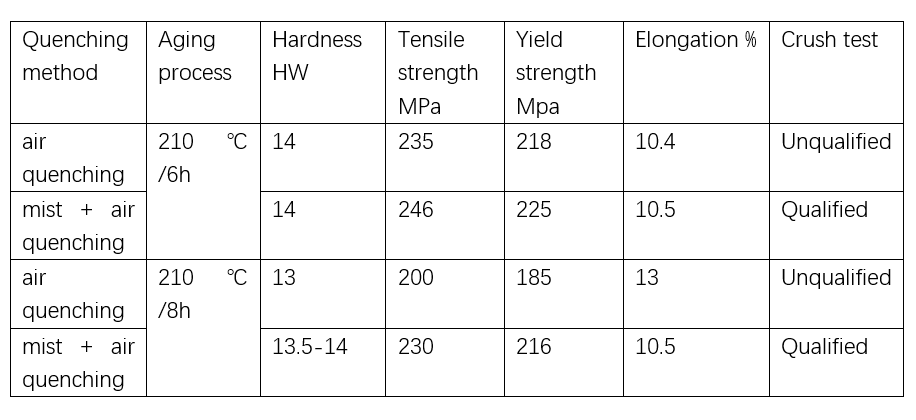

Kutevera kuchembera kweT6 pa 185 ° C kwemaawa matanhatu, kuomarara kwechinhu uye michina yemagetsi ndeaya anotevera:

Zvinoenderana neiyo T7 kuchembera pa210 ° C kwemaawa matanhatu ne8 maawa, kuoma kwezvinhu uye mashandiro emagetsi ndeaya anotevera:

Zvichienderana nedata rekuyedza, iyo mhute + mhepo yekudzima nzira, yakasanganiswa neiyo 210 ° C / 6h kuchembera maitiro, inosangana nezvinodiwa zveese ma mechanika kuita uye kupwanya kuyedzwa. Tichifunga nezvekuita mari, iyo mhute + yekudzima mhepo nzira uye 210 ° C/6h yekuchembera yakasarudzwa kuti igadzirwe kuzadzisa zvinodiwa nechigadzirwa.

3.3 Kupwanya Muedzo

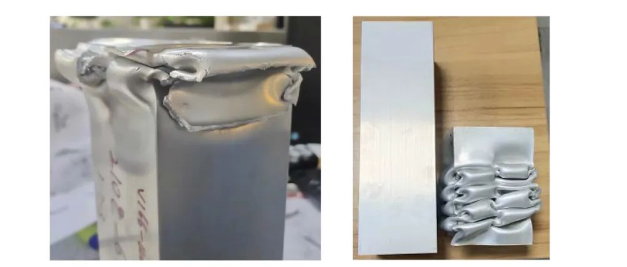

Kune tsvimbo yechipiri neyechitatu, musoro wekupedzisira unogurwa ne 1.5m, uye muswe wemuswe unogurwa ne 1.2m. Sampuli mbiri imwe neimwe inotorwa kubva kumusoro, yepakati, uye muswe zvikamu, nehurefu hwe300mm. Kupwanya bvunzo kunoitwa mushure mekuchembera pa185 ° C/6h uye 210 ° C/6h uye 8h (mechanical performance data sezvataurwa pamusoro) pamushini wepasi rose wekuyedza zvinhu. Iwo maedzo anoitwa pakurodha kumhanya kwe100 mm/min nekumanikidza kwe70%. Mhedzisiro yacho ndeyotevera: kune mhute + mhepo inodzima ne 210 ° C / 6h uye 8h maitiro ekukwegura, miedzo yekupwanya inosangana nezvinodiwa, sezvinoratidzwa muMufananidzo 3-2, apo sampuli dzakadzimwa nemhepo dzinoratidza kuputika kwemaitiro ose ekukwegura.

Zvichienderana nemhedzisiro yekupwanya bvunzo, mhute + mhepo inodzima ne210 ° C/6h uye 8h maitiro ekuchembera anosangana nezvinodiwa nemutengi.

4 Mhedziso

Iko optimization yekudzima uye kuchembera maitiro kwakakosha pakubudirira kwekugadzirwa kwechigadzirwa uye inopa yakanakira maitiro mhinduro kune crash box chigadzirwa.

Kuburikidza nekuyedzwa kwakawanda, zvakatemwa kuti mamiriro ezvinhu echigadzirwa chebhokisi rekuparara anofanirwa kunge ari 6063-T7, nzira yekudzima imhute + kutonhora kwemhepo, uye kuchembera pa210 ° C/6h ndiyo yakanakisa sarudzo yekuburitsa simbi dzealuminium nekupisa kubva pa480-500 ° C, extrusion shaft 480 ° C, 2.5 mm dhizaini yekupisa, 2. uye extrusion outlet tembiricha ye500-540°C.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: May-07-2024