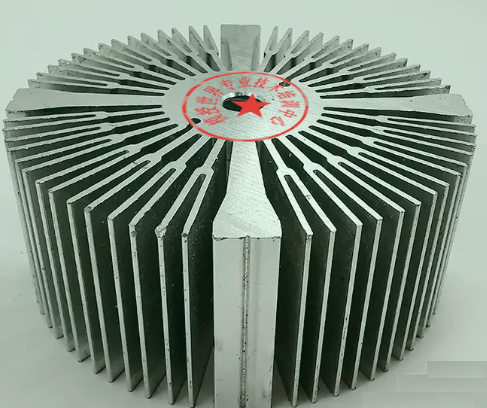

Nekuti aruminiyamu alloys akareruka, akanaka, ane corrosion resistance, uye ane yakanakisa thermal conductivity uye kugadzirisa kuita, anoshandiswa zvakanyanya sezvikamu zvekubvisa kupisa muIT indasitiri, zvemagetsi uye maindasitiri emotokari, kunyanya muindasitiri iri kubuda yeLED. Aya aluminium alloy heat dissipation zvikamu zvine mabasa akanaka ekupisa kupisa. Mukugadzira, kiyi yekubudirira kugadzirwa kweiyo radiator profiles ndiyo mold. Nekuti aya maprofiles anowanzo ane hunhu hwemazino makuru uye akaonda ekupisa kupisa uye machubhu akareba ekumisikidza, iyo yechinyakare flat die chimiro, kupatsanurwa kufa chimiro uye semi-hollow chimiro chekufa chimiro hachikwanise kuzadzisa zvinodiwa zvesimba rekuumbwa uye extrusion molding.

Parizvino, mabhizinesi anovimba zvakanyanya nemhando yesimbi yekuumbwa. Kuti vavandudze kusimba kweforoma, havazeze kushandisa simbi inodhura kubva kunze kwenyika. Mutengo weforoma wakakwira zvakanyanya, uye iyo chaiyo avhareji yehupenyu hweforoma isingasviki 3t, zvichikonzera mutengo wemusika weiyo radiator wakakwira zvakanyanya, zvichirambidza zvakanyanya kusimudzirwa uye kufarirwa kwemarambi eLED. Naizvozvo, extrusion inofa yeringazuva-yakaita radiator profiles yakwezva kutarisisa kukuru kubva kuinjiniya nevashandi vehunyanzvi muindastiri.

Ichi chinyorwa chinosuma akasiyana matekinoroji esunflower radiator profil extrusion kufa yakawanikwa kuburikidza nemakore ekutsvaga kunorwadza uye kudzokororwa kwekuyedza kugadzirwa kuburikidza nemienzaniso mukugadzirwa chaiko, kutariswa nevezera.

1. Kuongororwa kwemaitiro ekugadzirisa zvikamu zvealuminium profile

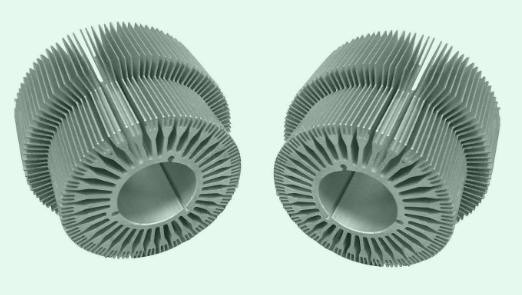

Mufananidzo 1 unoratidza muchinjiko-chikamu cheyakajairwa sunflower radiator aluminium profile. Iyo mhiri-chikamu nzvimbo yeiyo mbiri ndeye 7773.5mm², ine huwandu hwemakumi mana ekupisa mazino ekupisa. Iyo yakanyanya kurembera yekuvhura saizi yakaumbwa pakati pemeno ndeye 4.46 mm. Mushure mekuverenga, chiyero cherurimi pakati pemeno i15.7. Panguva imwecheteyo, kune nzvimbo yakakura yakasimba pakati peprofile, ine nzvimbo ye3846.5mm².

Tichitarisa kubva pachimiro chechimiro chechimiro, nzvimbo iri pakati pemeno inogona kutariswa semi-hollow profiles, uye iyo radiator mbiri inoumbwa neakawanda semi-hollow profiles. Naizvozvo, kana uchigadzira chimiro che mold, kiyi ndeye kufunga maitiro ekuona kusimba kweforoma. Kunyange zvazvo kune semi-hollow profiles, indasitiri yakagadzira zvakasiyana-siyana zvekugadzira mold zvimiro, zvakadai se "yakavharwa splitter mold", "cut splitter mold", "suspension bridge splitter mold", nezvimwewo. Zvisinei, zvigadziridzo izvi hazvishandi kune zvigadzirwa zvinoumbwa ne multiple semi-hollow profiles. Magadzirirwo echinyakare anongofunga zvekushandisa, asi mukuumba extrusion, iyo yakanyanya kukanganisa simba ndeye extrusion simba panguva ye extrusion process, uye simbi yekugadzira muitiro ndiyo huru inogadzira extrusion simba.

Nekuda kwenzvimbo yakakura yepakati yakasimba ye solar radiator profile, zviri nyore kwazvo kuita kuti huwandu hwekuyerera kwese munzvimbo ino hwuve nekukurumidza panguva yeextrusion process, uye iyo yakawedzera kushushikana kushushikana inogadzirwa pamusoro weiyo intertooth suspension chubhu, zvichikonzera kuputsika kweiyo intertooth suspension chubhu. Nokudaro, mukugadzirwa kwechimiro chechimiro, tinofanira kutarisa kugadziriswa kwesimbi yekuyerera uye kuyerera kwehuwandu kuti uwane chinangwa chekudzikisa extrusion pressure uye kuvandudza mamiriro ekushungurudzika kwepombi yakamiswa pakati pemeno, kuitira kuti uvandudze simba remuumbi.

2. Kusarudzwa kwechimiro chekuumbwa uye extrusion press capacity

2.1 Mold chimiro chimiro

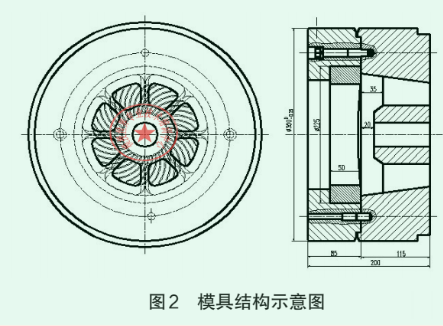

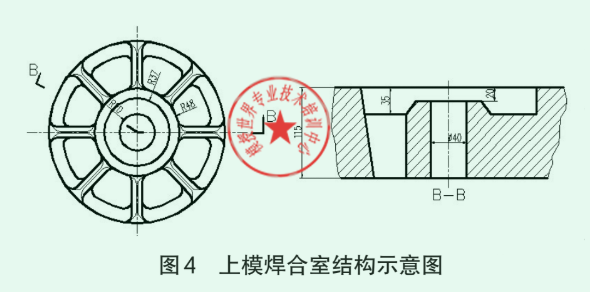

Nokuda kweiyo sunflower radiator profile inoratidzwa muMufananidzo 1, kunyange zvazvo isina chikamu chisina kujeka, inofanira kutora chimiro chechidimbu chekuparadzanisa sezvinoratidzwa muMufananidzo 2. Yakasiyana nemaitiro echinyakare shunt mold, kamuri yesimbi soldering station inoiswa muhuputi hwepamusoro, uye chigadziro chekuisa chinoshandiswa mumucheka wepasi. Chinangwa ndechekudzikisa mutengo wekuumbwa uye kupfupisa kutenderera kwekugadzira mold. Ose ari maviri epamusoro mold uye ezasi mold seti azere uye anogona kushandiswa zvakare. Zvinotonyanya kukosha, mabhuraki egomba anogona kugadziriswa akazvimirira, ayo anogona kuve nechokwadi chechokwadi chebhandi rebasa rekufa. Gomba remukati rezasi mold rakagadzirwa senhanho. Iyo yekumusoro chikamu uye iyo mold hole block inotora clearance fit, uye iyo gap kukosha pamativi ese ari 0.06 ~ 0.1m; chikamu chezasi chinotora kupindirana kwakakodzera, uye huwandu hwekupindira pamativi ese ari 0.02 ~ 0.04m, iyo inobatsira kuve nechokwadi che coaxiality uye kufambisa kuungana, ichiita kuti inlay ikwane zvakanyanya compact, uye panguva imwe chete, inogona kudzivirira kuumbwa kwe mold kunokonzerwa nekupisa kwekuisa kupindira kwekupindirana.

2.2 Kusarudzwa kweextruder capacity

Kusarudzwa kweiyo extruder simba ndeye, kune rumwe rutivi, kuona iyo yakakodzera yemukati dhayamita ye extrusion barrel uye yakanyanya kudzvanywa yakanangana neiyo extruder pane extrusion barrel chikamu kusangana nekumanikidza panguva yekugadzira simbi. Nekune rumwe rutivi, ndeyekuona iyo yakakodzera extrusion reshiyo uye sarudza yakakodzera mold saizi yakatarwa zvichienderana nemutengo. Kune sunflower radiator aluminium profile, iyo extrusion ratio haigone kuve yakakura kwazvo. Chikonzero chikuru ndechekuti iyo extrusion force inoenderana neiyo extrusion ratio. Iyo yakakura iyo extrusion ratio, iyo yakakura iyo extrusion simba. Izvi zvinokanganisa zvakanyanya kune sunflower radiator aluminium profile mold.

Chiitiko chinoratidza kuti extrusion ratio yealuminium profiles ye sunflower radiators iri pasi pe 25. Pamufananidzo wakaratidzwa mumufananidzo 1, 20.0 MN extruder ine extrusion barrel yemukati dhayamita ye208 mm yakasarudzwa. Mushure mekuverenga, iyo yakanyanya kunyanya kudzvanywa kweiyo extruder ndeye 589MPa, inova yakakosha kukosha. Kana kudzvinyirirwa kwakananga kwakanyanyisa, kudzvinyirirwa pane mold kuchave kwakakura, izvo zvinokanganisa hupenyu hwehuputi; kana iyo chaiyo yekumanikidza yakanyanya kuderera, haigone kusangana nezvinodiwa zve extrusion kuumba. Chiitiko chinoratidza kuti imwe kudzvanywa muhuwandu hwe550 ~ 750 MPa inogona kusangana zviri nani zvakasiyana-siyana zvinodiwa. Mushure mekuverenga, iyo extrusion coefficient ndeye 4.37. Iyo mold size yakasarudzika inosarudzwa se350 mmx200 mm (yekunze dhayamita x madhigirii).

3. Kutsunga kwe mold structural parameters

3.1 Yepamusoro mold zvimiro zvimiro

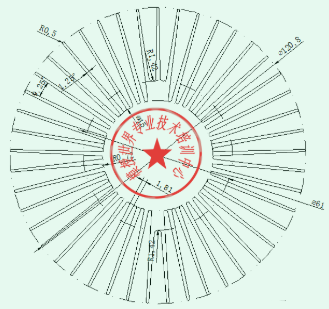

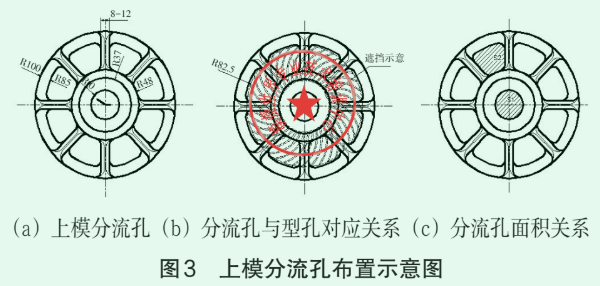

(1) Nhamba uye kurongeka kwemakomba ekutsausa. Kune sunflower radiator profile shunt mold, iyo yakawanda nhamba ye shunt maburi, zviri nani. Kune ma profiles ane akafanana denderedzwa maumbirwo, 3 kusvika 4 echinyakare shunt maburi anowanzo kusarudzwa. Mhedzisiro yacho ndeyekuti hupamhi hwebhiriji shunt hwakakura. Kazhinji, kana yakakura kudarika 20mm, nhamba ye welds ishoma. Zvisinei, pakusarudza bhanhire rekushanda regomba rinofa, bhanhire rekushanda refa gole riri pasi pebhiriji reshunt rinofanira kuva rakapfupika. Pasi pemamiriro ekuti hapana nzira yekuverenga chaiyo yekusarudzwa kwebhanhire rinoshanda, zvinongoita kuti gomba rekufa riri pasi pebhiriji uye zvimwe zvikamu risawane chiyero chakafanana chekuyerera panguva yeextrusion nekuda kwekusiyana kwebhandi rinoshanda. Naizvozvo, kune sunflower radiator extrusion inofa ine dense nhamba yemazino, zvakakosha kuti uve nechokwadi chekuti kuyerera kwezino rega rega kunoenderana. Sezvo huwandu hwemakomba eshunt hunowedzera, huwandu hwemabhiriji eshunt huchawedzera zvichienderana, uye kuyerera kwekuyerera uye kuyerera kwekugovera kwesimbi kuchawedzera zvakanyanya. Izvi zvinodaro nekuti sezvo huwandu hwemabhiriji eshunt hunowedzera, hupamhi hwemabhiriji eshunt hunogona kuderedzwa zvinoenderana.

Data rinoshanda rinoratidza kuti huwandu hwemakomba shunt kazhinji 6 kana 8, kana kutopfuura. Ehezve, kune mamwe mahombe ezuva ekupisa kupisa maprofiles, iyo yekumusoro mold inogona zvakare kuronga maburi eshunt zvinoenderana nemusimboti weiyo shunt bhiriji upamhi ≤ 14mm. Musiyano ndewekuti pamberi pekuparadzanisa ndiro inofanira kuwedzerwa kune pre-kugovera uye kugadzirisa kuyerera kwesimbi. Huwandu uye kurongeka kwemaburi e diverter mundiro yekumberi inogona kuitwa nenzira yechinyakare.

Mukuwedzera, pakuronga maburi eshunt, kufunga kunofanira kupiwa kushandiswa kwepamusoro mold kuti zvidzivirire zvakakodzera musoro we cantilever yezino rinopisa kupisa kudzivirira simbi kubva pakurova zvakananga musoro we cantilever tube uye nokudaro kuvandudza mamiriro ekunetseka kwe cantilever tube. Chikamu chakavharidzirwa chemusoro we cantilever pakati pemazino chinogona kuva 1/5 ~ 1/4 yehurefu hwe cantilever tube. Kurongeka kwemaburi eshunt kunoratidzwa muMufananidzo 3

(2) Hukama hwenzvimbo yegomba reshunt. Nemhaka yokuti rusvingo rwemadziro emudzi wezino rinopisa idiki uye kureba kuri kure nepakati, uye nzvimbo yepanyama yakasiyana zvikuru nepakati, ndiyo inonyanya kuoma chikamu chekugadzira simbi. Naizvozvo, chinhu chakakosha mukugadzirwa kweiyo sunflower radiator profile mold ndeyekuita kuti kuyerera kwechikamu chepakati chakasimba kunonoka sezvinobvira kuve nechokwadi chekuti simbi inotanga kuzadza mudzi wezino. Kuti uwane chiitiko chakadaro, kune rumwe rutivi, ndiko kusarudzwa kwebhanhire rekushanda, uye zvinonyanya kukosha, kutsunga kwenzvimbo yegomba re diverter, kunyanya nzvimbo yepakati yepakati inopindirana negomba re diverter. Miedzo uye empirical tsika dzinoratidza kuti yakanakisa mhedzisiro inowanikwa kana nzvimbo yepakati diverter gomba S1 uye nzvimbo yekunze imwe diverter gomba S2 inogutsa hukama hunotevera: S1 = (0.52 ~ 0.72) S2

Uye zvakare, iyo inoshanda simbi yekuyerera chiteshi chepakati chepakati chepakati chinofanirwa kuve chakareba 20 ~ 25mm pane inoshanda simbi inoyerera chiteshi chekunze chekupatsanura gomba. Kureba uku kunotorawo mucherechedzo uye mukana wekugadzirisa mold.

(3) Hudzamu hwekamuri yewelding. Iyo Sunflower radiator profile extrusion die yakasiyana neyechinyakare shunt kufa. Kamuri yaro yese yewelding inofanirwa kunge iri mune yekumusoro die. Izvi ndezvekuvimbisa kurongeka kwegomba rekugadzirisa kwekufa kwepasi, kunyanya kurongeka kwebhanhire rekushanda. Kuenzaniswa neyakajairwa shunt mold, kudzika kwekamuri yekubatira yeSunflower radiator profile shunt mold inoda kuwedzerwa. Iyo yakakura iyo extrusion muchina simba, iyo yakakura kuwedzera mukudzika kwekamuri yekubatira, inova 15 ~ 25mm. Semuenzaniso, kana muchina we20 MN extrusion uchishandiswa, kudzika kwekamuri yekubatira yechinyakare shunt kufa ndeye 20 ~ 22mm, nepo kudzika kwekamuri yekubatira yeshunt kufa kweiyo sunflower radiator mbiri kunofanirwa kuve 35 ~ 40 mm. Kubatsira kweizvi ndechokuti simbi yakanyungudutswa zvakakwana uye kushushikana kwepombi yakamiswa kwakaderedzwa zvikuru. Mamiriro ekamuri repamusoro rekugadzira mold inoratidzwa muMufananidzo 4.

3.2 Dhizaini yekuiswa kwegomba

Dhizaini yebhuroka rekufa rinonyanya kusanganisira saizi yegomba rekufa, bhandi rekushanda, dhayamita rekunze uye ukobvu hwegirazi block, nezvimwe.

(1) Kutemerwa kwehukuru hwegomba. Saizi yegomba rekufa inogona kutariswa nenzira yechinyakare, kunyanya tichifunga nezvekuyera kweiyo alloy thermal process.

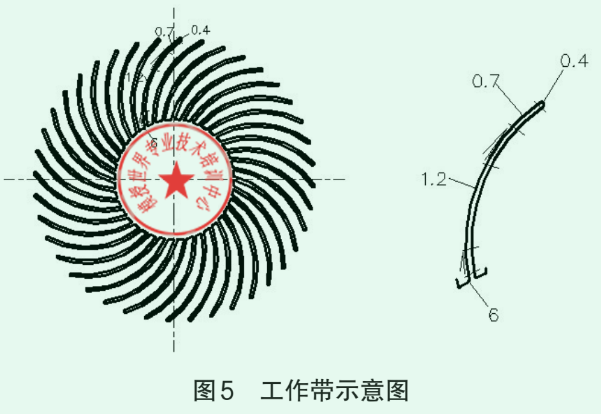

(2) Kusarudzwa kwebhandi rebasa. Nheyo yekushanda bhanhire kusarudzwa ndeyokutanga kuve nechokwadi kuti kugoverwa kwesimbi yose pasi pemudzi wezino yakakwana, kuitira kuti kuyerera kwemvura iri pasi pemudzi wezino kukurumidza kupfuura zvimwe zvikamu. Nokudaro, bhanhire rinoshanda riri pasi pemudzi wezino rinofanira kuva rakapfupika, rine kukosha kwe 0.3 ~ 0.6mm, uye bhanhire rinoshanda pamativi ari pedyo rinofanira kuwedzerwa ne 0.3mm. Nheyo yacho ndeyekuwedzera ne 0.4 ~ 0.5 yega yega 10 ~ 15mm yakananga pakati; chechipiri, bhanhire rinoshanda pachikamu chikuru chakasimba chepakati hachifanirwe kudarika 7mm. Kana zvisina kudaro, kana kureba kwekusiyana kwebhanhire rekushanda kwakanyanya, zvikanganiso zvakakura zvichaitika mukugadzirisa magetsi emhangura uye EDM kushandiswa kwebhanhire rinoshanda. Kukanganisa uku kunogona kuita nyore kuti kutsauka kwezino kutsemuka panguva ye extrusion process. Bhandi rebasa rinoratidzwa muMufananidzo 5.

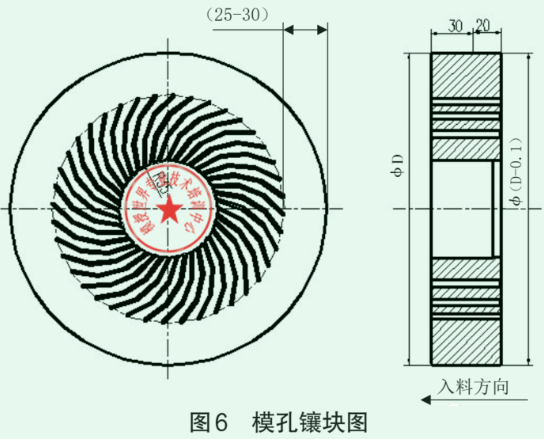

(3) Iyo yekunze dhayamita uye ukobvu hwekupinza. Kune zvechinyakare shunt molds, ukobvu hweiyo die hole inopinza ndiko ukobvu hweyakadzika mold. Nekudaro, kune sunflower radiator mold, kana iyo inobudirira yegomba rekufa yakakurisa, iyo profil inopindirana zviri nyore ne mold panguva yeextrusion uye kuburitsa, zvichikonzera mazino asina kuenzana, kukwenya kana kunyange mazino. Izvi zvichaita kuti mazino atyoke.

Mukuwedzera, kana hupamhi hwegomba rinofa rakareba, kune rumwe rutivi, nguva yekugadzira yakareba panguva yeEDM process, uye kune rumwe rutivi, zviri nyore kukonzera kuparara kwemagetsi, uye zvakare zviri nyore kukonzera kutsauka kwezino panguva ye extrusion. Ehe, kana iyo gomba rekufa rakanyanya kudiki, kusimba kwemeno hakugone kuvimbiswa. Naizvozvo, tichifunga nezvezvinhu zviviri izvi, chiitiko chinoratidza kuti dhigirii rekuisa gomba rezasi mold rinowanzo 40 kusvika 50; uye dhayamita rekunze rekupinza buri rinofanira kuva 25 kusvika 30 mm kubva kumucheto mukuru wegomba rekufa kusvika kune denderedzwa rekunze rekuisa.

Kune chimiro chinoratidzwa muFigure 1, iyo dhayamita yekunze uye ukobvu hwebhuroko rekufa i225mm uye 50mm zvakateerana. Kuiswa kwegomba rekufa kunoratidzwa muMufananidzo 6. D mumufananidzo ndiyo saizi chaiyo uye saizi yezita i225mm. Muganho wekutsauka kwezviyero zvayo zvekunze zvinofananidzwa nemukati megomba rezasi mold kuti ive nechokwadi chekuti unilateral gap iri mukati meiyo 0.01 ~ 0.02mm. Die hole block inoratidzwa muMufananidzo 6. Hukuru hwezita hwegomba remukati revharo yegomba rakaiswa pazasi mold i225mm. Zvichienderana nesaizi chaiyo yakayerwa, iyo die hole block inofananidzwa zvinoenderana nemusimboti we 0.01 ~ 0.02mm padivi. Iyo dhayamita yekunze yebhuroko rekufa inogona kuwanikwa seD, asi kuti zvive nyore kuisirwa, iyo dhayamita yekunze yeiyo die hole girazi block inogona kuderedzwa zvakafanira mukati meiyo 0.1m pakupera kwekudya, sezvakaratidzwa mumufananidzo.

4. Makiyi matekinoroji ekugadzira mold

Iko machining eSunflower radiator profile mold haina kunyanya kusiyana kubva kune yakajairwa aluminium profile molds. Kusiyana kwakajeka kunonyanya kuratidzwa mukugadzirisa magetsi.

(1) Mukutaura kwekucheka kwetambo, zvakakosha kudzivirira deformation ye electrode yemhangura. Nemhaka yokuti electrode yemhangura inoshandiswa kuEDM inorema, mazino acho ari maduku zvikuru, electrode pachayo yakapfava, ine urombo husina kusimba, uye kutonhora kwepamusoro kwepanzvimbo kunogadzirwa nekucheka kwetambo kunoita kuti electrode iite nyore nyore panguva yekucheka kwetambo. Paunenge uchishandisa ma electrode emhangura akaremara kugadzira mabhandi ebasa uye mapanga asina chinhu, mazino akatsvetwa achaitika, izvo zvinogona kuita kuti mold ibviswe panguva yekugadziriswa. Naizvozvo, zvinodikanwa kudzivirira deformation yemhangura electrode panguva yekugadzira online. Matanho makuru ekudzivirira ndeaya: musati macheka waya, enzanisa bhuroka yemhangura nemubhedha; shandisa dial indicator kugadzirisa verticality pakutanga; pakucheka waya, tanga kubva pazino, uye pakupedzisira cheka chikamu nemadziro akakora; Nguva nenguva, shandisa zvimedu zvesirivha waya kuzadza zvikamu zvakachekwa; mushure mekunge waya yagadzirwa, shandisa muchina wewaya kuti ucheke chikamu chipfupi chinenge 4 mm pamwe nehurefu hwe electrode yemhangura yakachekwa.

(2) Magetsi ekuburitsa machining zviri pachena kuti akasiyana neakajairwa mold. EDM yakakosha zvikuru mukugadzirisa kwe sunflower radiator profile molds. Kunyange kana iyo yakagadzirwa yakakwana, kukanganisa kuduku muEDM kuchaita kuti mold yose iparadzwe. Electric discharge machining haina kutsamira pamidziyo sekucheka waya. Zvinoenderana zvakanyanya nehunyanzvi hwekushandisa uye kugona kwemushandisi. Magetsi ekuburitsa machining anonyanya kutarisisa kune anotevera mapoinzi mashanu:

①Electric discharge machining ikozvino. 7 ~ 10 A ikozvino inogona kushandiswa kwekutanga EDM machining kupfupisa nguva yekugadzirisa; 5 ~ 7 A ikozvino inogona kushandiswa kupedzisa machining. Chinangwa chekushandisa diki ikozvino kuwana nzvimbo yakanaka;

② Ita shuwa kuti flatness ye mold yekupedzisira kumeso uye verticality yemhangura electrode. Urombo husina kunaka hwekuumbwa kwechiso chekupedzisira kana kusakwana verticality ye electrode yemhangura inoita kuti zvive zvakaoma kuve nechokwadi kuti kureba kwebhanhire rebasa mushure mekugadzirisa EDM kunopindirana nehurefu hwebhandi rebasa rakagadzirwa. Zviri nyore kuti EDM iite kuti ikundike kana kutopinda mukati mebhandi rebasa rine mazino. Nokudaro, isati yagadziriswa, grinder inofanira kushandiswa kugadzirisa migumo miviri ye mold kuti isangane nekururama kwezvinodiwa, uye chiratidzo chedhiyabhorosi chinofanira kushandiswa kugadzirisa verticality yemhangura electrode;

③ Ita shuwa kuti mukaha pakati pemapanga asina chinhu wakaenzana. Munguva yekutanga machining, tarisa kana chishandiso chisina chinhu chinodzikiswa yega yega 0.2 mm yega 3 kusvika 4 mm yekugadziriswa. Kana iyo yekubvisa yakakura, zvichange zvakaoma kuigadzirisa nekugadzirisa kunotevera;

④Bvisa zvakasara zvakagadzirwa panguva yeEDM process panguva yakakodzera. Spark discharge corrosion ichabudisa yakawanda yakasara, iyo inofanira kucheneswa munguva, kana zvisina kudaro kureba kwebhanhire rekushanda kuchave kwakasiyana nekuda kwehurefu hwakasiyana hwezvakasara;

⑤Iyo mold inofanira kubviswa magineti pamberi peEDM.

5. Kuenzanisa kwemigumisiro ye extrusion

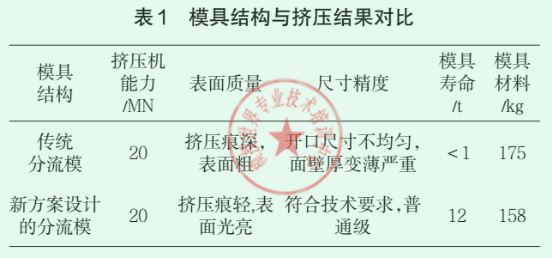

Iyo mbiri inoratidzwa muMufananidzo 1 yakaedzwa uchishandisa yechinyakare kupatsanurwa mold uye nyowani dhizaini chirongwa chakatsanangurwa muchinyorwa chino. Kuenzanisa kwemhedzisiro kunoratidzwa muTafura 1.

Inogona kuonekwa kubva pakuenzanisa migumisiro kuti chimiro che mold chine simba guru pahupenyu hwehutu. Iyo mold yakagadzirwa uchishandisa chirongwa chitsva ine mabhenefiti ari pachena uye inovandudza zvakanyanya hupenyu hwekuumbwa.

6. Mhedziso

Iyo sunflower radiator profil extrusion mold imhando yeforoma iyo yakaoma kwazvo kugadzira nekugadzira, uye magadzirirwo ayo uye kugadzira kwakati kuomarara. Naizvozvo, kuve nechokwadi cheiyo extrusion yekubudirira uye hupenyu hwesevhisi ye mold, zvinotevera mapoinzi anofanira kuwanikwa:

(1) Chimiro chechimiro chechimiro chinofanira kusarudzwa zvine musoro. Chimiro chemuumbi chinofanira kunge chakanakira kuderedza simba rekuwedzera kuderedza kushushikana pane mold cantilever inoumbwa nemazino ekupisa kupisa, nokudaro kuvandudza simba remuumbi. Chinokosha ndechokuona zvinonzwisisika nhamba uye kurongeka kwemakomba e shunt uye nzvimbo ye shunt holes uye mamwe maparameter: kutanga, hupamhi hwebhiriji reshunt rakagadzirwa pakati pe shunt holes harifaniri kudarika 16mm; Chechipiri, nzvimbo yakapatsanurwa yegomba inofanirwa kuve yakatemwa kuitira kuti kupatsanurwa kwechiyero kusvike kupfuura 30% yeiyo extrusion reshiyo zvakanyanya sezvinobvira uchisimbisa kusimba kweforoma.

(2) Sarudza zvine musoro bhandi rebasa uye tora matanho anonzwisisika panguva yekugadzira magetsi, kusanganisira tekinoroji yekugadzira yemhangura electrode uye yemagetsi zviyero zvemagetsi machining. Chinhu chekutanga chakakosha ndechekuti electrode yemhangura inofanirwa kunge iri pasi pasi pamberi pekucheka waya, uye nzira yekuisa inofanira kushandiswa panguva yekucheka waya kuti ive nechokwadi. Ma electrode haana kusununguka kana kuremara.

(3) Panguva yekugadzira magetsi, electrode inofanira kunyatsoenderana kuti irege kutsauka kwezino. Ehezve, pahwaro hwekugadzira uye kugadzira kunonzwisisika, kushandiswa kwemhando yepamusoro-yemhando yekupisa-basa simbi yesimbi uye vacuum kupisa kurapwa maitiro matatu kana anopfuura ehasha anogona kuwedzera kugona kwe mold uye kuwana mhedzisiro iri nani. Kubva pakugadzira, kugadzira kusvika pakugadzirwa kweextrusion, chete kana chinongedzo chega chega chakarurama isu tinogona kuve nechokwadi chekuti sunflower radiator profile mold yakawedzerwa.

Nguva yekutumira: Aug-01-2024