Kurerutsa kwemotokari chinangwa chakagovaniswa cheindasitiri yemotokari yepasi rose. Kuwedzera kushandiswa kwezvinhu zvealuminium alloy muzvikamu zvemotokari ndiyo nhungamiro yekusimudzira yemotokari dzemazuva ano dzemhando itsva. 6082 aruminiyamu alloy inorapa kupisa, yakasimbisa aluminium alloy ine simba riri pakati nepakati, yakanakisa kuumbwa, weldability, kuneta kuramba, uye corrosion resistance. Iyi alloy inogona kukwidziridzwa kuita mapaipi, tsvimbo, uye profiles, uye inoshandiswa zvakanyanya muzvikamu zvemotokari, welded zvimiro zvikamu, zvekufambisa, uye indasitiri yekuvaka.

Parizvino, pane tsvakiridzo shoma pa6082 aruminiyamu alloy yekushandisa mumotokari nyowani dzemagetsi muChina. Naizvozvo, ichi chidzidzo chekuyedza chinoongorora mhedzisiro ye6082 aluminium alloy element yemukati renji, extrusion process paramita, nzira dzekudzima, nezvimwe, pane iyo alloy profil mashandiro uye microstructure. Ichi chidzidzo chine chinangwa chekugadzirisa alloy kuumbwa uye kuita maparamendi kuti abudise 6082 aruminiyamu alloy zvinhu zvakakodzera mota nyowani dzesimba.

1. Test Materials uye Nzira

Experimental process flow: Alloy composition ratio – Ingot melting – Ingot homogenization – Ingot sawing into billets – Extrusion of profiles – In-line quenching of profiles – Artificial kuchembera – Gadziriro yebvunzo sampuli.

1.1 Ingot Kugadzirira

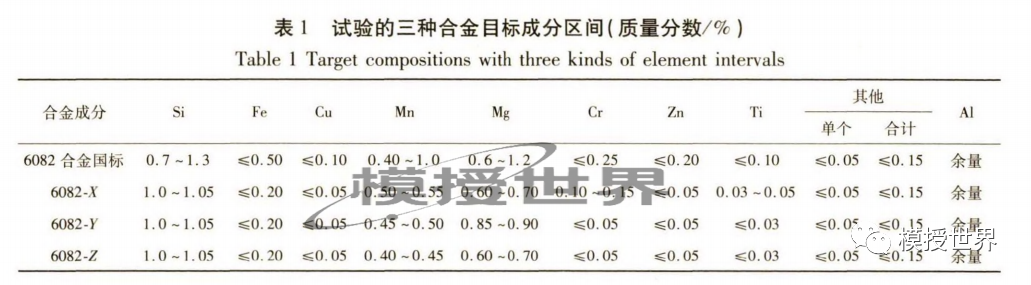

Mukati merudzi rwepasi rose rwe6082 aruminiyamu alloy nziyo, nziyo nhatu dzakasarudzwa dzine madiki ekudzora mazinga, akanyorwa se 6082-/6082 ″, 6082-Z, ine zvakafanana Si element zvirimo. Mg zvinhu zvemukati, y > z; Mn zvinhu zvemukati, x > y > z; Cr, Ti chinhu chemukati, x > y = z. Iyo chaiyo alloy kuumbwa kwechinangwa chetsika inoratidzwa muTebhu 1. Ingot casting yakaitwa uchishandisa semi-inopfuurira mvura-inotonhorera yekukanda nzira, inoteverwa nehomogenization kurapwa. Ingot dzese dziri nhatu dzakaitwa homogenized pachishandiswa fekitori yakatangwa pa560°C kwemaawa maviri nekutonhodza mhute yemvura.

1.2 Kuwedzeredzwa kweProfiles

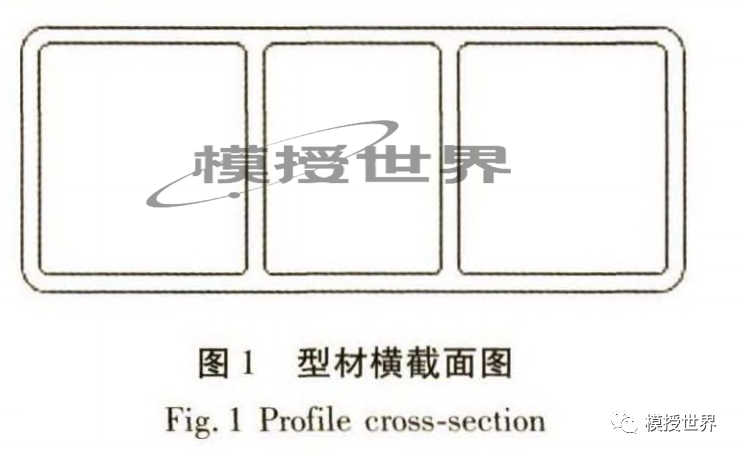

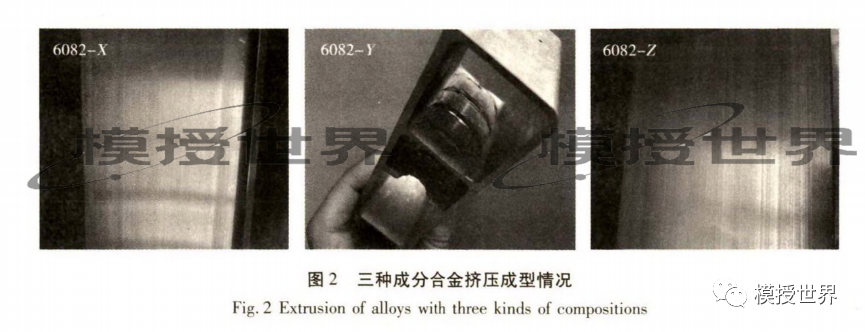

Iyo extrusion process paramita yakagadziridzwa zvakafanira billet kupisa tembiricha uye quenching kutonhora mwero. Muchinjikwa-chikamu chezvinyorwa zvakasvibiswa zvinoratidzwa muMufananidzo 1. Maitiro ekugadzirisa maitiro anoratidzwa muTebhu 2. Mamiriro ekuumba ezvinyorwa zvakasvibiswa zvinoratidzwa mumufananidzo 2.

2.Test Results uye Analysis

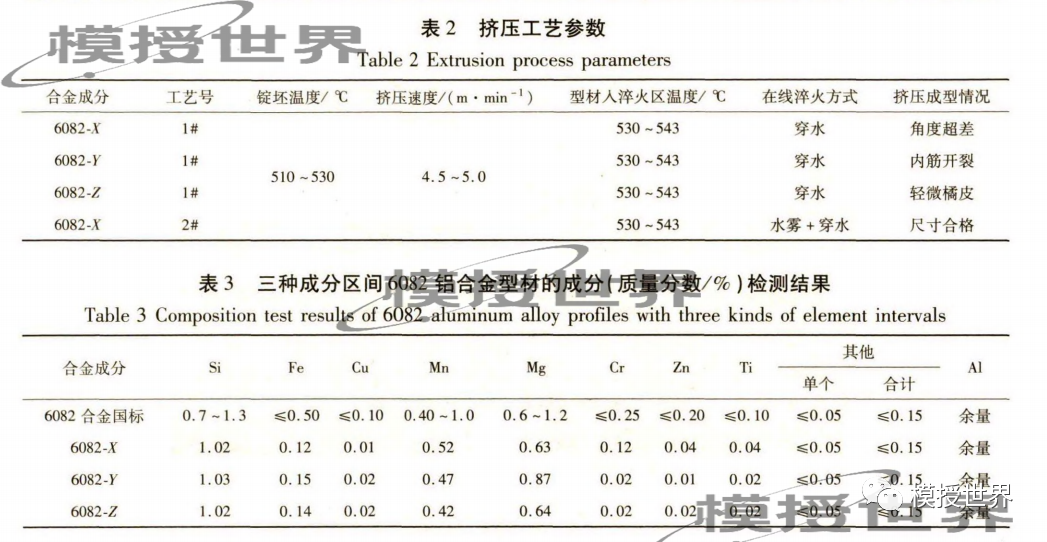

Iyo chaiyo yekemikari ye6082 aruminiyamu alloy profiles mukati mezvikamu zvitatu zvekuumbwa zvakatemerwa uchishandisa Swiss ARL yakananga kuverenga spectrometer, sezvakaratidzwa muTable 3.

2.1 Performance Testing

Kuti uenzanise, kuita kweatatu emhando yemhando alloy profiles ane akasiyana nzira dzekudzima, akafanana extrusion paramita, uye kuchembera maitiro akaongororwa.

2.1.1 Mechanical Performance

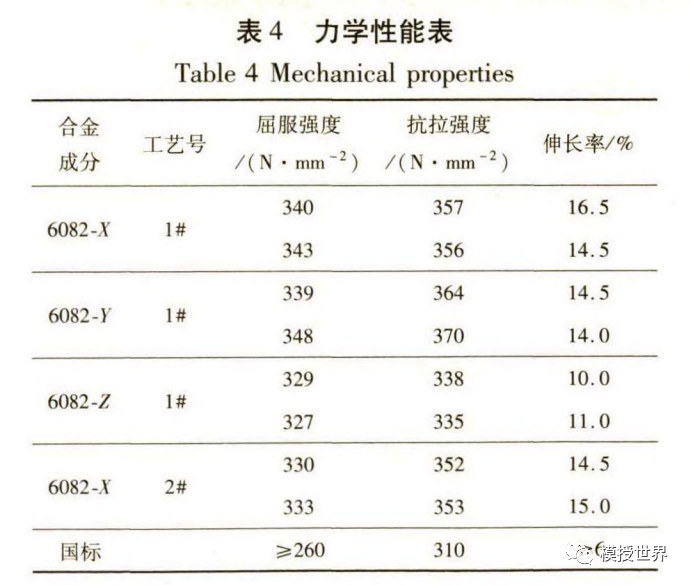

Mushure mekuchembera kwekugadzira pa175 ° C kwemaawa masere, zvienzaniso zvakajairwa zvakatorwa kubva kwakanangana neextrusion yemaprofayiri ekuyedza kusimba pachishandiswa Shimadzu AG-X100 yemagetsi universal test machine. Mechanical performance mushure mekuchembera kwekugadzira kwakasiyana uye nzira dzekudzima inoratidzwa muTafura 4.

Kubva paTafura 4, zvinogona kuonekwa kuti mashandiro emuchina emaprofiles ese anodarika chiyero chenyika. Maprofayiri akagadzirwa kubva ku6082-Z alloy billets aive neakadzika elongation mushure mekutyoka. Maprofayiri akagadzirwa kubva ku6082-7 alloy billets aive nepamusoro pemechani kuita. 6082-X alloy profiles, ine nzira dzakasiyana dzakasimba dzekugadzirisa, dzakaratidza kushanda kwepamusoro nekukurumidza kutonhora kudzima nzira.

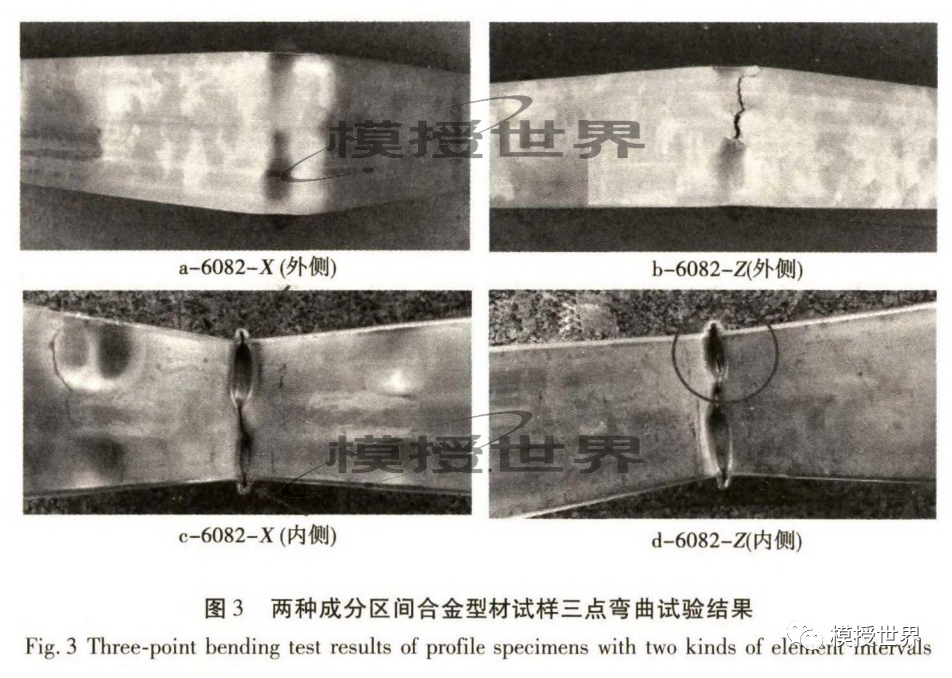

2.1.2 Bending Performance Testing

Uchishandisa michina yemagetsi yekuongorora yepasirese, matatu-point bending bvunzo dzakaitwa pamasamples, uye mhedzisiro yekukotama inoratidzwa muMufananidzo 3. Mufananidzo 3 unoratidza kuti zvigadzirwa zvinogadzirwa kubva ku6082-Z alloy billets zvaive zvakanyanya orange peel pamusoro uye kuputika kumashure kweakabhenda samples. Zvigadzirwa zvakagadzirwa kubva ku6082-X alloy mabhiridha zvaive nani kubhenda kuita, nzvimbo dzakatsetseka dzisina ganda reorenji, uye madiki madiki chete pazvinzvimbo zvakaganhurirwa nemamiriro ejometri kuseri kwemasamples akabhenda.

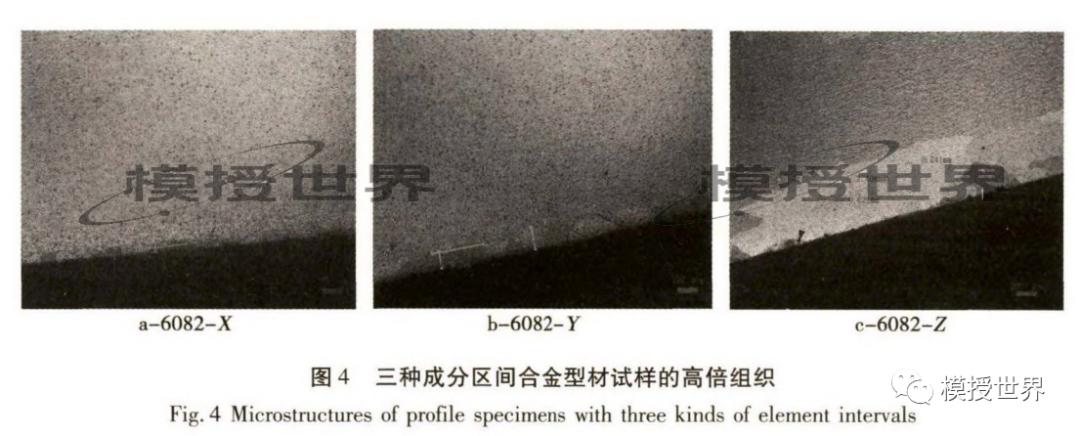

2.1.3 Kuongorora kwepamusoro-soro

Mienzaniso yakaonekwa pasi peCarl Zeiss AX10 optical microscope ye microstructure analysis. Iyo microstructure yekuongorora inoguma yematatu ekuumbwa kwemhando yealloy profiles inoratidzwa muFigure 4. Mufananidzo 4 inoratidza kuti saizi yezviyo zvezvigadzirwa zvakagadzirwa kubva ku6082-X tsvimbo uye 6082-K alloy billets yakanga yakafanana, ine zvishoma zviri nani saizi yezviyo mu6082-X alloy kana ichienzaniswa ne6082-y alloy. Zvigadzirwa zvakagadzirwa kubva ku6082-Z alloy billets zvaive nehukuru hwezviyo uye zvakakora cortex layer, izvo zvaitungamira nyore kune pear orenji peel uye kushaya simba kwemukati simbi kubatana.

2.2 Ongororo yemhedzisiro

Zvichienderana nemhedzisiro yebvunzo iri pamusoro, zvinogona kugumiswa kuti dhizaini yemhando yekuumbwa kwealloy inokanganisa zvakanyanya iyo microstructure, kuita, uye kuumbwa kwemaprofiles akawedzerwa. Iyo yakawedzera Mg element yemukati inoderedza alloy plasticity uye inotungamira mukutsemuka kuumbwa panguva yeextrusion. Yepamusoro Mn, Cr, uye Ti zvemukati zvine mhedzisiro yakanaka pakunatsa iyo microstructure, iyo inozove inokanganisa kunaka kwepamusoro, kuita kwekukotama, uye kuita kwese.

3. Mhedziso

Mg element inokanganisa zvakanyanya mashandiro emuchina we6082 aluminium alloy. Iyo yakawedzera Mg yemukati inoderedza alloy plasticity uye inotungamira mukutsemuka kuumbwa panguva yeextrusion.

Mn, Cr, uye Ti vane mhedzisiro yakanaka pakunatswa kwemicrostructure, zvichitungamira kukuvandudzwa kwemhando yepamusoro uye kubhenda kuita kwezvigadzirwa zvakawedzerwa.

Yakasiyana yekudzimisa kutonhora kusimba kune inooneka maitiro pakuita kwe6082 aruminiyamu alloy profiles. Pakushandisa mota, kutora nzira yekudzima mhute yemvura inoteverwa nekupfapfaidza yemvura kutonhora kunopa kuita kurinani kwemuchina uye kunovimbisa chimiro cheprofile uye kurongeka kwechimiro.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Mar-26-2024