Munguva yeextrusion process yealuminium alloy extruded materials, kunyanya aruminiyamu profiles, "gomba" kukanganisa kunowanzoitika pamusoro. Iwo chaiwo maratidziro anosanganisira madiki mabundu ane akasiyana densities, muswe, uye pachena ruoko kunzwa, ane spiky kunzwa. Mushure me oxidation kana electrophoretic pamusoro pekurapa, ivo vanowanzoonekwa sematema granules anonamatira pamusoro pechigadzirwa.

Mukugadzirwa kweextrusion yemaprofiles makuru-chikamu, kukanganisa uku kunowanzoitika nekuda kwesimba reiyo ingot chimiro, extrusion tembiricha, extrusion speed, mold complexity, etc. Zvizhinji zvezvimedu zvakanaka zvepitted defects zvinogona kubviswa panguva yeprofile surface pretreatment process, kunyanya alkali etching process, nepo nhamba shomanana yehukuru hwakanyanya hutsika hunoramba huripo pahutano hwekupedzisira, hunoita hutsika hwekupedzisira hunoita kuti huve hunoita kuti huve husina kunaka. chigadzirwa.

Mune zvakajairwa zvivakwa zvekuvaka gonhi nemahwindo zvigadzirwa, vatengi vanowanzo gamuchira zvidiki zvirema, asi kune maindasitiri profiles anoda kukoshesa kwakaenzana pamichina zvivakwa uye yekushongedza kuita kana kunyanya kukoshesa kuita kwekushongedza, vatengi havagamuchire chikanganiso ichi, kunyanya hurema husingaenderane neyakasiyana ruvara rwekumashure.

Kuti uongorore kuumbwa kwemaitiro ezvimedu zvakakasharara, morphology uye kuumbwa kwenzvimbo dzakakanganisika pasi pemhando dzakasiyana dzealloy uye extrusion maitiro akaongororwa, uye kusiyana pakati pekukanganisa uye matrix kwakaenzaniswa. Mhinduro inonzwisisika yekugadzirisa zvinobudirira zvimedu zvakakasharara yakaiswa pamberi, uye bvunzo yekuedzwa yakaitwa.

Kuti ugadzirise kukanganisa kwegomba kwemaprofile, zvinodikanwa kuti unzwisise nzira yekugadzira yekuremara kwegomba. Munguva ye extrusion process, aruminiyamu inonamira kune kufa kushanda bhandi ndiyo honzeri huru yekukanganisa kwegomba pamusoro peiyo extruded aruminiyamu zvinhu. Izvi zvinodaro nekuti extrusion process yealuminium inoitwa pakupisa kwepamusoro kunosvika 450°C. Kana zvinokonzeresa deformation kupisa uye friction kupisa zvakawedzerwa, tembiricha yesimbi ichave yakakwirira kana ichiyerera ichibuda mugomba rekufa. Kana chigadzirwa chichiyerera kubva mugomba rekufa, nekuda kwekupisa kwakanyanya, pane chiitiko chealuminium inonamira pakati pesimbi uye mold inoshanda bhandi.

Chimiro chekubatana uku kunowanzo: kudzokororwa kwechisungo - kubvarura - kusungirirwa - kubvarura zvakare, uye chigadzirwa chinoyerera mberi, zvichiita kuti pave nemakomba maduku akawanda pamusoro pechigadzirwa.

Ichi chiitiko chekubatanidza chine hukama nezvinhu zvakaita semhando yeingot, mamiriro epamusoro ebhandi rekushanda kwe mold, tembiricha yeextrusion, kukurumidza kwekuwedzera, dhigirii re deformation, uye deformation kuramba kwesimbi.

1 Test zvinhu uye nzira

Kuburikidza nekutsvagisa kwekutanga, takadzidza kuti zvinhu zvakaita semetallurgical kuchena, mold chimiro, extrusion process, zvinongedzo, uye mamiriro ekugadzira anogona kukanganisa pamusoro roughened zvimedu. Mukuedzwa, matanda maviri alloy, 6005A uye 6060, akashandiswa kuburitsa chikamu chimwe chete. Iyo morphology uye kuumbwa kweiyo roughened particle zvinzvimbo zvakaongororwa kuburikidza neakananga kuverenga spectrometer uye SEM nzira dzekuona, uye zvichienzaniswa neyakatenderedza matrix.

Kuti tinyatso kusiyanisa morphology yezvakaremara zviviri zvegomba uye zvimedu, zvinotsanangurwa sezvizvi:

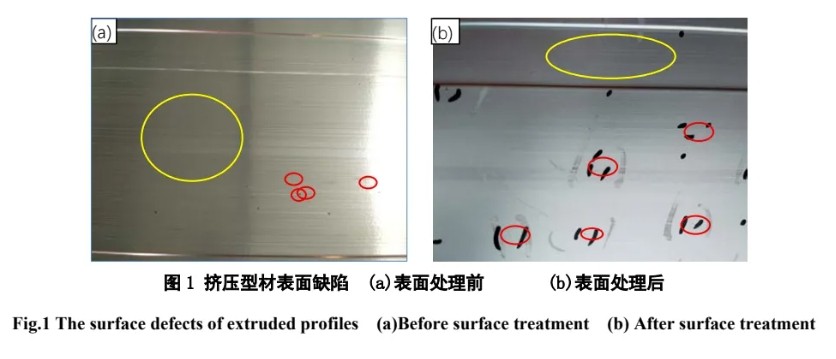

(1) Hurema hwegomba kana hurema hwekudhonza imhando yekuremara kwepoindi inova isina kujairika tadpole-yakaita kana point-yakafanana scratch defect inoonekwa pamusoro peiyo profil. Kuremara kunotanga kubva pamutsetse uye kunopera nekuremara kudonha, kuungana kuita bhinzi dzesimbi panoperera mutsara wekukwenya. Saizi yekuremara kwegomba kazhinji 1-5mm, uye inoshanduka yakasviba yakasviba mushure mekurapa oxidation, izvo zvinozokanganisa kutaridzika kweiyo mbiri, sezvakaratidzwa mudenderedzwa dzvuku mumufananidzo 1.

(2) Surface particles anonziwo simbi bhinzi kana adsorption particles. Iyo yepamusoro yealuminium alloy mbiri yakasungirirwa ne spherical grey-dema yakaoma simbi particles uye ine yakasununguka chimiro. Kune marudzi maviri ealuminium alloy profiles: ayo anogona kudzimwa uye ayo asingagone kudzimwa. Saizi yacho kazhinji isingasviki 0.5mm, uye inonzwa rough pakubata. Hapana kukwenya muchikamu chepamberi. Mushure me oxidation, haina kunyanya kusiyana nematrix, sezvakaratidzwa mudenderedzwa reyero mumufananidzo 1.

2 Miedzo mhinduro uye ongororo

2.1 Madhiri ekudhonza pamusoro

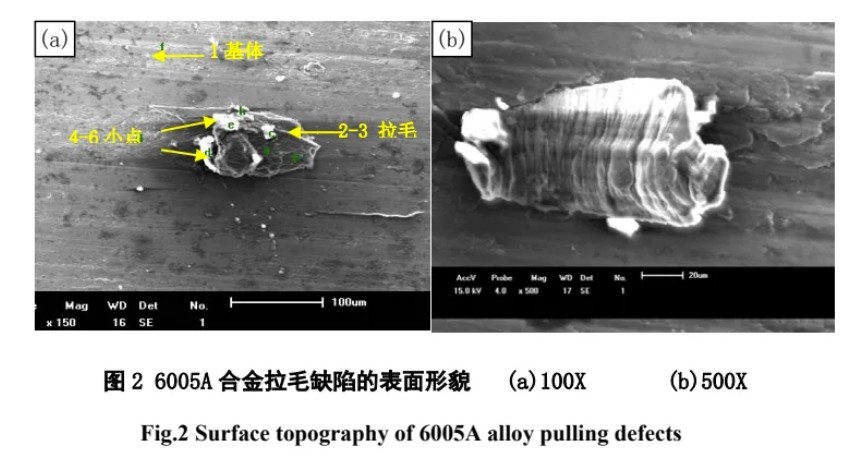

Mufananidzo 2 unoratidza iyo microstructural morphology yekudhonza kukanganisa pamusoro peiyo 6005A alloy. Kune nhanho-kunge makwara kumberi kwechikamu chekudhonza, uye anopera nemanodule akaturikidzana. Mushure mekuonekwa kwemanodule, nzvimbo yacho inodzokera kune yakajairika. Nzvimbo ye roughening chirema haina kutsvedzerera pakubata, ine inopinza minzwa kunzwa, uye inonamatira kana kuunganidza pamusoro peiyo profil. Kuburikidza neextrusion test, yakaonekwa kuti kudhonza morphology ye6005A uye 6060 extruded profiles yakafanana, uye muswe wekupedzisira wechigadzirwa unopfuura musoro; mutsauko ndewekuti saizi yese yekudhonza ye6005A idiki uye kudzika kwekukwenya kwakadzikira. Izvi zvinogona kunge zvine hukama nekuchinja mukuumbwa kwealloy, cast rod state, uye mold mamiriro. Kucherechedzwa pasi pe100X, kune akajeka mavanga ekumberi kwenzvimbo yekudhonza, iyo yakarebeswa pamwe neiyo extrusion nzira, uye chimiro chekupedzisira nodule particles hachina kurongeka. Pa500X, kumucheto kwepamberi kwenzvimbo yekudhonza kune nhanho-kunge zvikweshwa padivi penzira yekuwedzeredza (saizi yechikanganiso ichi ingangoita 120 μm), uye kune akajeka akaturikidzana mamaki pane nodular particles kumucheto wemuswe.

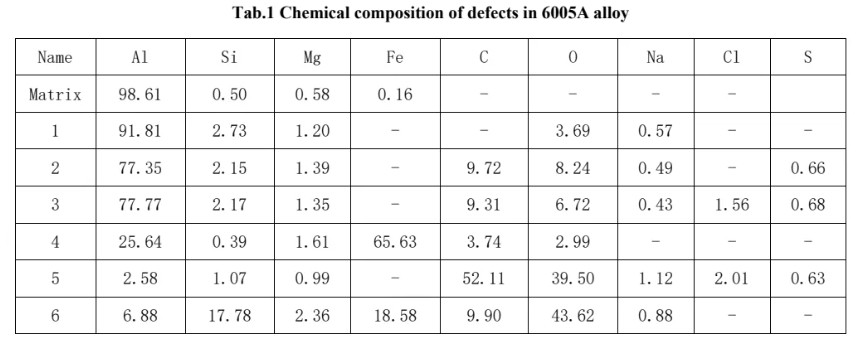

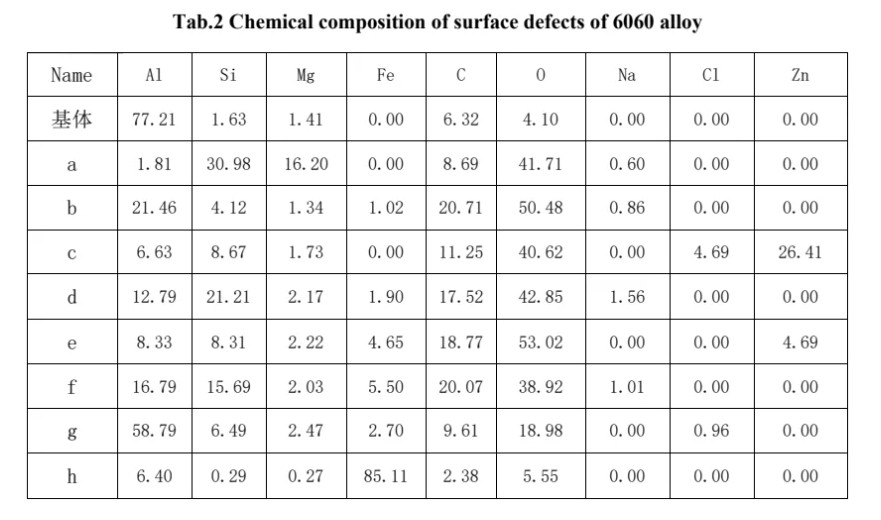

Kuti uongorore zvikonzero zvekudhonza, kuverenga kwakananga spectrometer uye EDX yakashandiswa kuita chikamu chekuongorora panzvimbo dzakaremara uye matrix ezvikamu zvitatu zvealloy. Tafura 1 inoratidza mhinduro dzebvunzo dze6005A mbiri. Mhedzisiro yeEDX inoratidza kuti kuumbwa kwenzvimbo yekumisikidza yezvimedu zvekudhonza zvakangofanana neiyo yematrix. Pamusoro pezvo, zvimwe zvimedu zvetsvina zvinounganidzwa mukati nekutenderedza chirema chekudhonza, uye zvidimbu zvetsvina zvine C, O (kana Cl), kana Fe, Si, uye S.

Ongororo yezvakaremara zve6005A yakanaka oxidized extruded profiles inoratidza kuti zvidimbu zvekudhonza zvakakura muhukuru (1-5mm), iyo nzvimbo inonyanya kurongedzerwa, uye kune nhanho-sekukwenya kumberi; Iko kuumbwa kuri padyo neAl matrix, uye kuchave neakasiyana-siyana zvikamu zvine Fe, Si, C, uye O zvakagovaniswa pairi. Zvinoratidza kuti iyo yekudhonza yekugadzira michina yeatatu alloys yakafanana.

Munguva ye extrusion process, simbi inoyerera friction ichaita kuti kutonhora kwebhandi rekushanda kwe mold kukwire, kuumba "sticky aluminium layer" pamucheto wekucheka wekupinda bhandi rekushanda. Panguva imwecheteyo, yakawandisa Si uye zvimwe zvinhu zvakaita seMn naCr mualuminium alloy zviri nyore kugadzira mhinduro yakasimba neFe, iyo inosimudzira kuumbwa kwe "sticky aluminium layer" pamusuwo wemold working zone.

Sezvo simbi inoyerera ichienda mberi uye ichikwesha kurwisana nebhandi rebasa, chiitiko chinodzokororwa chekuenderera kwekubatana-kubvarura-chisungo chinoitika pane imwe nzvimbo, zvichiita kuti simbi irambe ichikwira panzvimbo iyi. Kana zvimedu zvikawedzera kune imwe saizi, Iyo inodhonzwa kure neinoyerera chigadzirwa uye kugadzira mavanga mavanga pamusoro pesimbi. Icharamba iri pamusoro pesimbi uye inoita kudhonza zvimedu pamagumo ekukwenya. saka, zvinogona kutariswa kuti kuumbwa kwe roughened particles kunonyanya kuenderana nearuminiyamu inonamatira kune mold inoshanda bhandi. Zvikamu zvakasiyana-siyana zvakagoverwa kumativi ose zvinogona kubva mumafuta ekuzora, okisidhi kana guruva, pamwe chete netsvina inounzwa nekukasharara kweingot.

Nekudaro, iyo nhamba yekudhonza mu6005A bvunzo mhinduro idiki uye dhigirii rakareruka. Kune rumwe rutivi, imhaka yechamfering pakubuda kwebhandi rekushanda kwe mold uye kunyatsokwenenzverwa kwebhanhire rekushanda kuderedza kukora kwealuminium layer; kune rumwe rutivi, ine hukama kune yakawandisa Si yemukati.

Zvinoenderana neakananga kuverenga spectral kuumbwa kwemhedzisiro, zvinogona kuoneka kuti mukuwedzera kune Si yakasanganiswa neMg Mg2Si, iyo yakasara Si inoonekwa muchimiro chechinhu chiri nyore.

2.2 Zvimedu zvidiki pamusoro

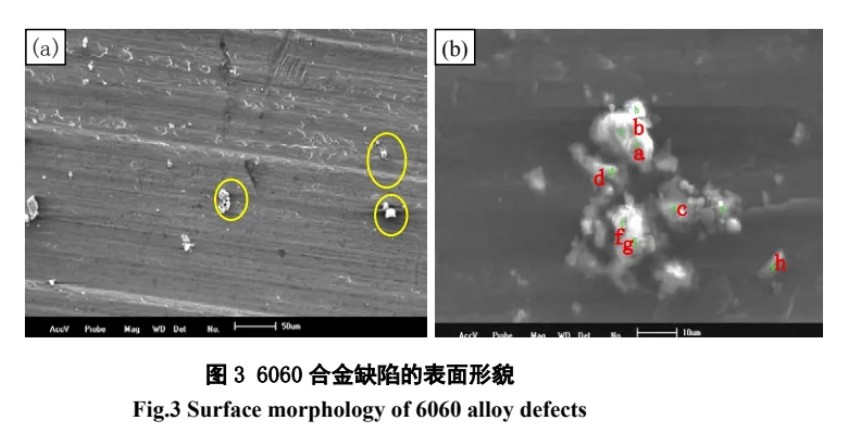

Pasi pekutarisa kwakadzika-kukudza kwekutarisa, zvimedu zvidiki (≤0.5mm), kwete kutsvedzerera pakubata, zvine manzwiro akapinza, uye anonamatira pamusoro peiyo profil. Kucherechedzwa pasi pe100X, zvidimbu zvidiki zviri pamusoro zvinogoverwa zvisina tsarukano, uye kune madiki-madiki madiki akasungirirwa pamusoro zvisinei nekuti pane zvikwambo kana kwete;

Pa500X, zvisinei kana paine zviri pachena nhanho-senge makwara pamusoro peiyo extrusion nzira, zvidimbu zvakawanda zvichiri zvakabatanidzwa, uye hukuru hukuru hunosiyana. Saizi yakakura kwazvo inenge 15 μm, uye diki diki dzinenge 5 μm.

Kuburikidza nekuongororwa kwekuumbwa kwe6060 alloy surface particles uye intact matrix, zvimedu zvinonyanya kuumbwa neO, C, Si, uye Fe zvinhu, uye zvinyorwa zvealuminium zvakaderera zvikuru. Zvinenge zvese zvimedu zvine O uye C zvinhu. Kuumbwa kwechikamu chimwe nechimwe kwakasiyana zvishoma. Pakati pavo, zvidimbu zviri pedyo ne10 μm, iyo yakakwirira zvikuru kupfuura matrix Si, Mg, uye O; Mu c zvidimbu, Si, O, uye Cl zviri pachena kuti akakwirira; Zvimedu d uye f zvine high Si, O, uye Na; zvidimbu e ane Si, Fe, uye O; h zvimedu zvinosanganiswa neFe-containing. Migumisiro yezvikamu zve6060 zvakafanana neizvi, asi nokuti Si uye Fe zvinyorwa mu6060 pachayo zvakaderera, izvo zvinoenderana neSi uye Fe zviri mukati mezvikamu zvepasi zvakare zvakaderera; iyo C yemukati mu6060 zvidimbu zvakaderera.

Zvimedu zvepamusoro zvinogona kunge zvisiri zvidiki zvidiki, asi zvinogonawo kuvepo muchimiro chekuunganidzwa kwezvimedu zvidiki zvakawanda zvine maumbirwo akasiyana, uye huwandu hwehuwandu hwezvinhu zvakasiyana muzvikamu zvakasiyana zvinosiyana. Zvinotendwa kuti zvimedu zvinonyanya kuumbwa nemhando mbiri. Imwe inonaya yakaita seAlFeSi uye elemental Si, iyo inotangira kubva pakakwirira kunyunguduka nzvimbo yekusachena senge FeAl3 kana AlFeSi(Mn) muingot, kana precipitate nhanho panguva ye extrusion process. Imwe ndeye adherent foreign matter.

2.3 Mhedzisiro yekukasharara kwe ingot

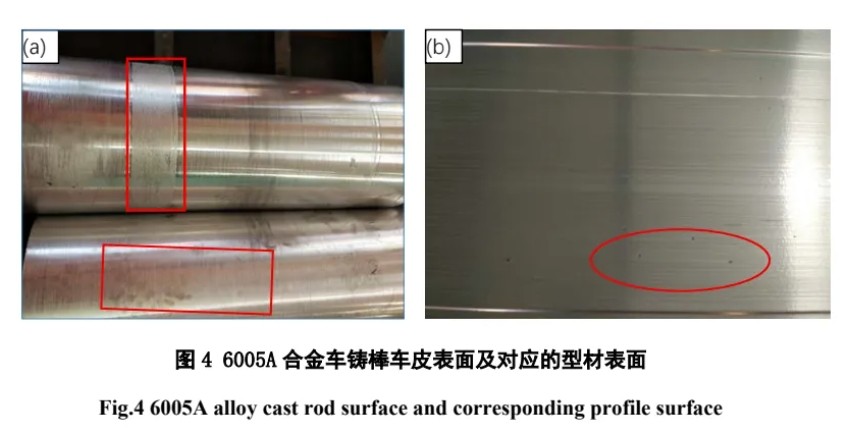

Munguva yekuedzwa, zvakaonekwa kuti kumashure kwe6005A cast rod lathe yakanga yakaoma uye yakasvibiswa neguruva. Paive nematanda maviri ekukanda ane akadzika maturusi ekushandisa mamaki munzvimbo dzenzvimbo, ayo aienderana nekuwedzera kukuru kwenhamba yekudhonza mushure mekuwedzera, uye saizi yekudhonza kamwe chete yaive yakakura, sezvakaratidzwa mumufananidzo 7.

Iyo 6005A yakakandwa tsvimbo haina lathe, saka kushata kwepamusoro kwakadzikira uye huwandu hwekudhonza hushoma. Uye zvakare, sezvo pasina yakawandisa yekucheka mvura yakasungirirwa kune lathe mamaki edanda rakakandwa, iyo C yemukati muzvikamu zvinoenderana inoderedzwa. Zvinoratidzwa kuti kutendeuka mamaki pamusoro petsvimbo yakakandwa anowedzera kudhonza uye kuumbwa kwechikamu kune imwe nhanho.

3 Kukurukurirana

(1) Izvo zvikamu zvekudhonza zvirema zvakangofanana neizvo zvematrix. Ndiyo zvidimbu zvekune imwe nyika, ganda rekare pamusoro pe ingot uye mamwe matsvina akaunganidzirwa mu extrusion barrel wall kana nzvimbo yakafa ye mold panguva ye extrusion process, iyo inounzwa kune simbi pamusoro kana aluminium layer ye mold inoshanda bhandi. Sezvo chigadzirwa chichiyerera mberi, kukwenya kwepamusoro kunokonzerwa, uye kana chigadzirwa chacho chichiunganidza kune imwe saizi, chinotorwa kunze nechigadzirwa kuti chigadzire kudhonza. Mushure me oxidation, kudhonza kwakasvibiswa, uye nekuda kwehukuru hwayo, pakanga paine hurema hwakaita segomba ipapo.

(2) Zvimedu zvepamusoro dzimwe nguva zvinoonekwa sezvimedu zvidiki, uye dzimwe nguva zviripo muchimiro chakaunganidzwa. Kuumbwa kwavo sezviri pachena kwakasiyana neiyo yematrix, uye kunyanya ine O, C, Fe, uye Si zvinhu. Zvimwe zvezvimedu zvinotongwa neO neC zvinhu, uye zvimwe zvimedu zvinotongwa neO, C, Fe, uye Si. Nokudaro, zvinofungidzirwa kuti zvimedu zvepamusoro zvinobva kune maviri: imwe inoputika yakadai seAlFeSi uye elemental Si, uye tsvina yakadai seO uye C inonamatira kumusoro; Imwe ndeye adherent foreign matter. Izvo zvimedu zvinosvibiswa kure mushure mekuita oxidation. Nekuda kwehukuru hwavo hudiki, ivo havana kana zvishoma zvinokanganisa pamusoro.

(3) Zvimedu zvakapfuma muC uye O zvinhu zvinonyanya kubva kumafuta ekuzora, guruva, ivhu, mweya, nezvimwe zvakanamatira pamusoro peingot. Izvo zvikamu zvikuru zvemafuta ekuzora ndeye C, O, H, S, nezvimwewo, uye chikamu chikuru cheguruva nevhu iSiO2. Iyo O yemukati yepasi particles inowanzokwira. Nekuti zvimedu zviri mumamiriro ekupisa kwepamusoro pakarepo mushure mekusiya bhandi rekushanda, uye nekuda kwenzvimbo yakakura chaiyo yezvimedu, zviri nyore adsorb O maatomu mumhepo uye kukonzera oxidation mushure mekusangana nemhepo, zvichikonzera O content yakakwira kupfuura matrix.

(4) Fe, Si, nezvimwewo zvinonyanya kubva kune oxides, chiyero chekare uye kusachena kwezvikamu mu ingot (high melting point kana chikamu chechipiri chisina kubviswa zvakakwana ne homogenization). Iyo Fe element inotangira kubva kuFe mualuminium ingots, ichigadzira yakakwira melting point kusachena nhanho senge FeAl3 kana AlFeSi (Mn), iyo isingagone kunyungudika mune yakasimba mhinduro panguva yehomogenization process, kana isina kushandurwa zvizere; Si iripo mune aluminium matrix muchimiro cheMg2Si kana supersaturated yakasimba mhinduro yeSi panguva yekukanda maitiro. Munguva yekupisa extrusion process yedanda rakakandwa, yakawandisa Si inogona kudonha. Kunyungudika kweSi mualuminium i0.48% pa450°C uye 0.8% (wt%) pa500°C. Iyo yakawandisa yeSi yemukati mu6005 ingangoita 0.41%, uye iyo yakawedzera Si inogona kunge iri kuunganidzwa uye kunaya kwemvura kunokonzerwa nekuchinja kwekutarisa.

(5) Aluminium inonamatira kune mold inoshanda bhandi ndiyo inonyanya kukonzera kudhonza. Iyo extrusion die inzvimbo yakakwirira-yekupisa uye yakakwirira-kumanikidza nharaunda. Metal flow friction inowedzera tembiricha yebhandi rekushanda re mold, ichigadzira "sticky aluminium layer" pamucheto wekucheka wekupinda bhandi rekushanda.

Panguva imwecheteyo, yakawandisa Si uye zvimwe zvinhu zvakaita seMn naCr mualuminium alloy zviri nyore kugadzira mhinduro yakasimba neFe, iyo inosimudzira kuumbwa kwe "sticky aluminium layer" pamusuwo wemold working zone. Simbi inoyerera ne "sticky aluminium layer" ndeyekukweshana kwemukati (sliding shear mukati mesimbi). Iyo simbi inoremara uye inoomesa nekuda kwekukweshana kwemukati, izvo zvinosimudzira simbi yepasi uye mold kuti ibatane pamwechete. Panguva imwecheteyo, bhandi rekushanda kwe mold rakakanganiswa kuita chimiro chehwamanda nekuda kwekumanikidzwa, uye iyo inonamira aluminium inogadzirwa nekucheka kumucheto chikamu chebhandi rinoshanda rinosangana neprofile rakafanana nekucheka kwechishandiso chekutendeuka.

Kuumbwa kwealuminium inonamira inzira ine simba yekukura nekudurura. Zvimedu zvinogara zvichibudiswa kunze neprofile.Kunamatira kumusoro kwechimiro, kuumba kukanganisa kudhonza. Kana iyo inoyerera yakananga kunze kwebhandi rebasa uye pakarepo yakashambadzirwa pamusoro peiyo profil, zvidimbu zvidiki zvakanamirwa nekushisa kumusoro zvinonzi "adsorption particles". Kana zvimwe zvimedu zvichaputswa neiyo extruded aluminium alloy, zvimwe zvimedu zvinonamatira kumusoro kwebhandi rebasa kana uchipfuura nepakati pebhandi rebasa, zvichikonzera kukwenya pamusoro peiyo profil. Muswe wekupedzisira ndiyo yakaturikidzana aluminium matrix. Kana paine aruminiyamu yakawanda yakanamatira pakati pebhandi rebasa (chisungo chakasimba), chinowedzera kukwenya kwepamusoro.

(6) The extrusion speed ine simba guru pakudhonza. Kufurira kweextrusion speed. Nezve iyo yakateedzerwa 6005 alloy ine chekuita, iyo extrusion yekumhanyisa inowedzera mukati meyedzo renji, tembiricha yekubuda inowedzera, uye huwandu hwepamusoro hwekudhonza zvidimbu hunowedzera uye hunowedzera huremu sezvo mitsara yemagetsi inowedzera. Iyo extrusion yekumhanyisa inofanirwa kuchengetwa yakatsiga sezvinobvira kudzivirira kamwe kamwe shanduko mukumhanya. Yakawandisa extrusion kumhanya uye yakakwirira yekubuda tembiricha inotungamira kune yakawedzera kukweshera uye yakakomba particle kudhonza. Iyo chaiyo nzira yekukanganisa kweextrusion kumhanya pane inodhonza phenomenon inoda kunotevera kutevedzera uye kuongororwa.

(7) Hunhu hwepamusoro hwetsvimbo yakakandwa zvakare chinhu chakakosha chinokanganisa kudhonza zvidimbu. Pamusoro petsvimbo yakakandwa yakaoma, ine sawing burrs, mavara emafuta, guruva, corrosion, nezvimwewo, izvo zvose zvinowedzera tsika yekudhonza zvidimbu.

4 Mhedziso

(1) Kuumbwa kwekudhonza kukanganisa kunopindirana neiyo yematrix; kuumbwa kwechikamu chechikamu chiri pachena chakasiyana neiyo yematrix, kunyanya ine O, C, Fe, uye Si zvinhu.

(2) Kudhonza chidimbu kukanganisa kunonyanya kukonzerwa nealuminium inonamatira kune mold inoshanda bhandi. Chero zvinhu zvinosimudzira aluminium kunamatira kune mold inoshanda bhandi zvinokonzeresa kudhonza hurema. Pamusoro pemamiriro ekuvimbisa kunaka kwetsvimbo yakakandwa, chizvarwa chekudhonza zvimedu hazvina kukanganisa zvakananga pakuumbwa kwealloy.

(3) Yakakodzera yunifomu moto kurapwa kunobatsira kuderedza kudhonzwa kwepamusoro.

Nguva yekutumira: Sep-10-2024