Huru rusvingo ukobvu 6061T6 aruminiyamu alloy inoda kudzimwa mushure mekupisa extrusion. Nekuda kwekudzikisira kwekusiya extrusion, chikamu cheprofile chichapinda munzvimbo inotonhorera yemvura nekunonoka. Kana iyo ingot ipfupi inotevera ichienderera mberi ichiwedzeredzwa, chikamu ichi cheprofile chinononoka kudzimwa. Maitiro ekuita nenzvimbo yakanonoka yekudzima inyaya inofanirwa kutariswa nekambani yega yega yekugadzira. Kana iyo extrusion muswe magumo process tsvina ipfupi, masampula ekuita anotorwa dzimwe nguva anokwanisa uye dzimwe nguva haana kukodzera. Paunenge uchidzokorora kubva padivi, mashandiro acho anokodzera zvakare. Ichi chinyorwa chinopa tsananguro inoenderana kuburikidza nekuedza.

1. Test zvinhu uye nzira

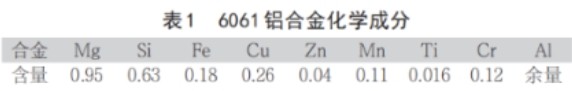

Zvinhu zvakashandiswa mukuyedza iyi 6061 aluminium alloy. Kemikari yaro yakayerwa nekuongororwa kwe spectral ndeyekutevera: Inopindirana neGB/T 3190-1996 yepasi rose 6061 aluminium alloy composition standard.

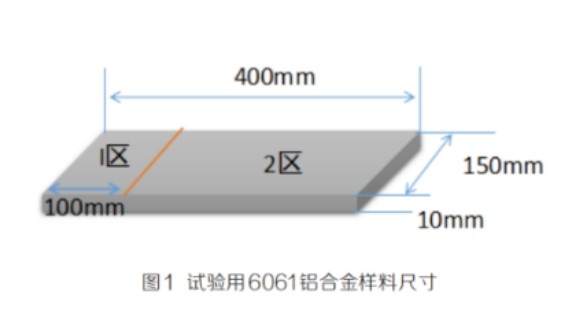

Muchiyedzo ichi, chikamu cheiyo extruded profile yakatorwa kune yakasimba mhinduro kurapwa. Iyo 400mm yakareba mbiri yakakamurwa kuita nzvimbo mbiri. Nzvimbo 1 yakananga mvura-yakatonhodzwa uye yakadzimwa. Nzvimbo 2 yakatonhodzwa mumhepo kwemasekonzi makumi mapfumbamwe uyezve mvura-yatonhodzwa. Iyo dhizaini yekuyedza inoratidzwa muMufananidzo 1.

Iyo 6061 aluminium alloy mbiri yakashandiswa muchiyedzo ichi yakawedzerwa ne4000UST extruder. Iyo tembiricha yekuumbwa ndeye 500 ° C, tembiricha yekukanda tsvimbo ndeye 510 ° C, tembiricha yekubuda kunze i525 ° C, iyo extrusion yekumhanyisa i2.1mm / s, kutonhora kwemvura kwakanyanya kunoshandiswa panguva yekuburitsa, uye 400mm kureba bvunzo chidimbu chinotorwa kubva pakati peiyo extruded yakapera profiles. Muenzaniso wehupamhi ndeye 150mm uye kureba i10.00mm.

Samples dzakatorwa dzakapatsanurwa uye dzakazoiswa kune mhinduro kurapwa zvakare. Iyo tembiricha yemhinduro yaive 530 ° C uye nguva yekugadzirisa yaive maawa mana. Mushure mekuaburitsa, masampuli akaiswa mutangi hombe remvura rine mvura yakadzika 100mm. Iyo tangi yakakura yemvura inogona kuve nechokwadi chekuti tembiricha yemvura mutangi remvura inochinja zvishoma mushure mekunge sampu iri muzone 1 yatonhodzwa nemvura, kudzivirira kuwedzera kwekushisa kwemvura kubva pakukanganisa kutonhora kwemvura. Panguva yekutonhora kwemvura, ita shuwa kuti tembiricha yemvura iri mukati meiyo 20-25 ° C. Masampuli akadzimwa aive akwegura pa165 ° C * 8h.

Tora chikamu chemuenzaniso 400mm kureba 30mm yakafara 10mm gobvu, uye ita Brinell kuomarara bvunzo. Ita zviyero zvishanu pa10mm yega yega. Tora avhareji kukosha kwe5 Brinell kuomarara semhedzisiro yekuoma kweBrinell panguva ino, uye tarisa kuoma kwekuchinja maitiro.

Iyo yemagetsi zvimiro zveprofile yakaedzwa, uye iyo tensile parallel chikamu 60mm yaidzorwa munzvimbo dzakasiyana dze400mm sampuli kuti itarise kusimba kwezvivakwa uye nzvimbo yekutsemuka.

Nzvimbo yekushisa yemvura-yakatonhodzwa kudzima kwemuenzaniso uye kudzima mushure mekunonoka kwe90s yakafananidzwa kuburikidza ne ANSYS software, uye kutonhora kwemazinga ezvinyorwa panzvimbo dzakasiyana kwakaongororwa.

2. Migumisiro yekuedza uye kuongorora

2.1 Kuoma bvunzo mhinduro

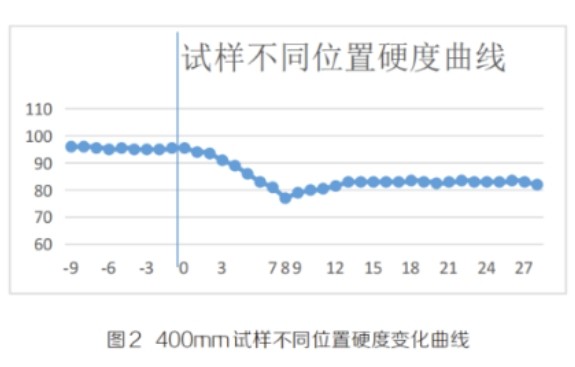

Mufananidzo 2 unoratidza kuoma kwekuchinja curve ye400mm kureba sampuli yakayerwa neBrinell hardness tester (iyo unit urefu hweabscissa inomiririra 10mm, uye 0 chiyero mutsara unopatsanura pakati penguva dzose quenching uye kunonoka kudzima). Zvinogona kuwanikwa kuti kuoma pamagumo emvura-yakatonhodzwa yakagadzikana pakutenderera 95HB. Mushure memutsara wekuparadzanisa pakati pemvura-kutonhora kudzima uye kunonoka 90s mvura-kutonhora kudzima, kuoma kunotanga kuderera, asi kuderera kunonoka mukutanga. Mushure me40mm (89HB), kuoma kunodonha zvakanyanya, uye kudonha kusvika kune yakaderera kukosha (77HB) pa80mm. Mushure me80mm, kuoma hakuna kuramba kuderera, asi kwakawedzera kune imwe nhanho. Wedzero yacho yakanga iri duku zvikuru. Mushure me130mm, kuomarara kwakaramba kusina kuchinjika pakutenderedza 83HB. Zvinogona kufungidzira kuti nekuda kwekuita kwekupisa conduction, kutonhora kwechikamu chakanonoka chekudzima chakachinja.

2.2 Performance bvunzo mhinduro uye ongororo

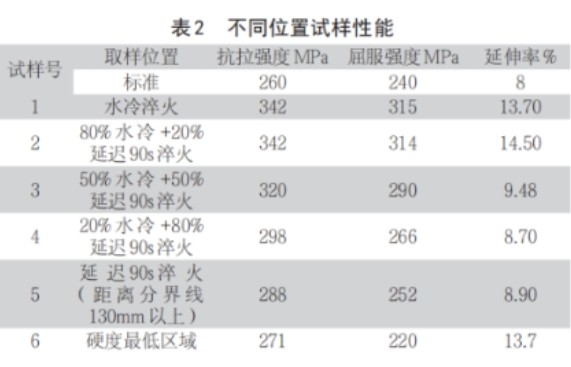

Tafura 2 inoratidza mibairo yekuedza kusimba kwakaitwa pamasampuli akatorwa kubva munzvimbo dzakasiyana dzechikamu chakafanana. Inogona kuwanikwa kuti kusimba kwesimba uye kubereka simba reNo. 1 uye Nha. Sezvo chikamu chekunonoka kudzima magumo chinowedzera, kusimba kwesimba uye goho reiyo alloy inoratidza yakakosha kudzika maitiro. Nekudaro, iyo simba rekusimba panzvimbo yega yega sampling iri pamusoro pesimba rakajairwa. Chete munzvimbo ine kuoma kwakaderera, simba regoho rakaderera pane chiyero chemuenzaniso, kushanda kwemuenzaniso hauna kukodzera.

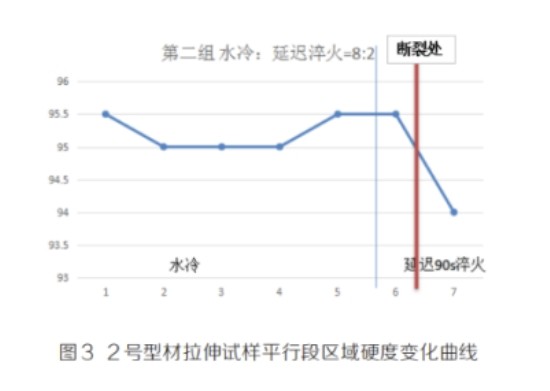

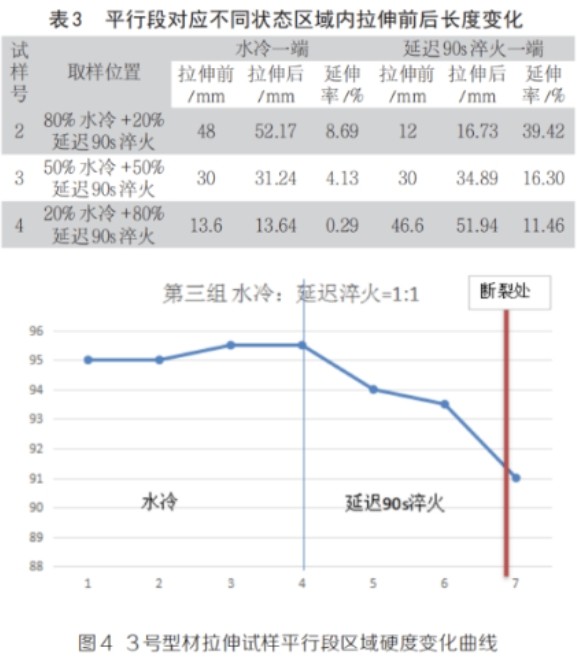

Mufananidzo 4 unoratidza maitiro ekugadzirisa migumisiro yemuenzaniso Nhamba 3. Inogona kuwanikwa kubva kuMufananidzo 4 kuti kure kure nemutsara wekuparadzanisa, kuderera kwekuoma kwekunonoka kwekudzima kuguma. Kuderera kwekuoma kunoratidza kuti kushanda kwemuenzaniso kwakaderedzwa, asi kuoma kunoderera zvishoma nezvishoma, kungoderera kubva ku95HB kusvika kune 91HB pakuguma kwechikamu chakafanana. Sezvinoonekwa kubva pamhedzisiro yekuita muTafura 1, simba rekusimba rakadzikira kubva pa342MPa kuenda pa320MPa yekutonhodza mvura. Panguva imwecheteyo, zvakaonekwa kuti nzvimbo yekuputsika yemuenzaniso wetensile iriwo pamagumo echikamu chakafanana nekuoma kwakaderera. Izvi zvinodaro nekuti iri kure nekutonhora kwemvura, kuita kwealloy kunoderedzwa, uye magumo anosvika padanho resimba rekutanga kugadzira mutsipa pasi. Chekupedzisira, pwanya kubva padanho repasi rekuita, uye nzvimbo yekuzorora inoenderana nemhedzisiro yebvunzo dzekuita.

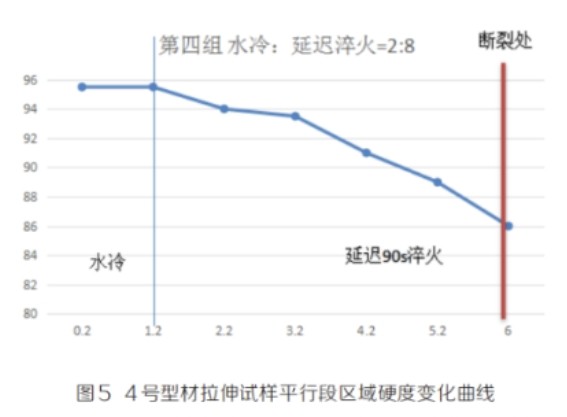

Mufananidzo 5 unoratidza kuoma kwakaoma kwechikamu chakafanana chemuenzaniso Nhamba 4 uye nzvimbo yekuputsika. Inogona kuwanikwa kuti kure kure nemvura-inotonhorera kupatsanura mutsara, yakaderera kuoma kunonoka quenching kuguma. Panguva imwecheteyo, nzvimbo yekuputsika iri zvakare kumagumo uko kuomarara kwakadzikira, 86HB kuputsika. Kubva paTafura 2, inowanikwa kuti pane inenge isina deformation yepurasitiki pamagumo emvura-yakanyorova. Kubva paTafura 1, inowanikwa kuti sampuli yekuita (tensile simba 298MPa, goho 266MPa) yakaderedzwa zvakanyanya. Kusimba kwesimba kunongova 298MPa, iyo isingasviki simba regoho rekupera kwemvura-yakatonhorera (315MPa). Mhedziso yakagadzira mutsipa pasi kana yakadzikira pane 315MPa. Pamberi pekutsemuka, chete elastic deformation yakaitika munzvimbo yakanyoroveswa nemvura. Sezvo kushushikana kwakanyangarika, kunetseka pamagumo emvura-yakanyoroveswa yakanyangarika. Nekuda kweizvozvo, iyo deformation huwandu munzvimbo inotonhorera yemvura muTafura 2 inenge isina shanduko. Muenzaniso unoputsika pakupera kwekunonoka chiyero chemoto, nzvimbo yakakanganiswa inoderedzwa, uye iyo yekupedzisira kuomarara ndiyo yakaderera, zvichikonzera kuderera kukuru kwemhedzisiro yekushanda.

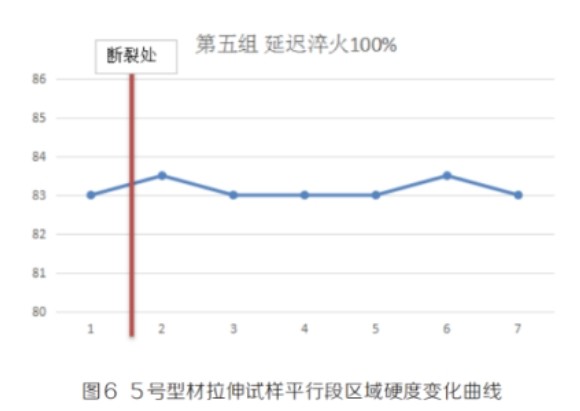

Tora sampuli kubva ku100% yakanonoka kudzima nzvimbo pakupera kwe400mm specimen. Mufananidzo 6 unoratidza kuomarara curve. Kuoma kwechikamu chakafanana kunoderedzwa kusvika pa83-84HB uye yakanyatsogadzikana. Nekuda kwekuita kwakafanana, kuita kwakafanana. Hapana chimiro chakajeka chinowanikwa munzvimbo yekuputsika. Iyo alloy performance yakaderera pane iyo yemvura-yakadzimwa sampuli.

Kuti uwedzere kuongorora kugarisa kwekuita uye kutsemuka, chikamu chakafanana cheiyo tensile specimen yakasarudzwa padyo nenzvimbo yakaderera yekuoma (77HB). Kubva paTafura 1, zvakaonekwa kuti kushanda kwakaderedzwa zvakanyanya, uye nzvimbo yakaputsika yakaonekwa panzvimbo yakaderera yekuoma muMufananidzo 2.

2.3 ANSYS yekuongorora zvabuda

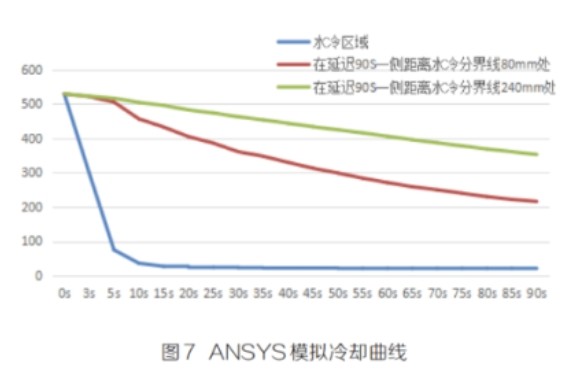

Mufananidzo 7 unoratidza mhedzisiro yeANSYS simulation yekutonhora macurves panzvimbo dzakasiyana. Zvinogona kuonekwa kuti kutonhora kwemuenzaniso munzvimbo yemvura-inotonhorera yakadonha nokukurumidza. Mushure me5s, tembiricha yakadonha kusvika pasi pe100 ° C, uye pa80mm kubva pamutsetse wekuparadzanisa, tembiricha yakadonha kusvika pa210 ° C pa90s. Avhareji yetembiricha inodonha i3.5°C/s. Mushure memasekonzi makumi mapfumbamwe munzvimbo yekutonhodza mhepo, tembiricha inodzika kusvika pa360°C, neavhareji yekudonha kwe1.9°C/s.

Kuburikidza nekuongorora kwekuita uye mhedzisiro yekuenzanisa, inowanikwa kuti kushanda kwenzvimbo yekutonhora kwemvura uye kunonoka kudzima nzvimbo inzira yekuchinja inotanga kuderera uye yobva yawedzera zvishoma. Inokonzerwa nekutonhodza kwemvura pedyo nemutsara wekuparadzanisa, kupisa kwekushisa kunoita kuti sampu mune imwe nzvimbo idonhe pamwero wekutonhodza zvishoma pane wekutonhora kwemvura (3.5 ° C / s). Nekuda kweizvozvo, Mg2Si, iyo yakaomeswa mumatrix, yakanaya muhuwandu hukuru munzvimbo iyi, uye tembiricha yakadzika kusvika pa210 ° C mushure memasekondi makumi mapfumbamwe. Huwandu hukuru hweMg2Si hwakanaya hwakatungamira kune diki mhedzisiro yekutonhora kwemvura mushure me90 s. Huwandu hweMg2Si yekusimbisa chikamu chakadzikiswa mushure mekuchembera kurapwa kwakaderedzwa zvakanyanya, uye semuenzaniso wekuita wakazoderedzwa. Zvisinei, iyo inononoka yekudzima nzvimbo iri kure nemutsara wekuparadzanisa hainyanyi kukanganiswa nemvura inotonhora kupisa conduction, uye alloy inotonhora zvishoma nezvishoma pasi pemamiriro ekutonhora kwemhepo (kutonhora kwe1.9 ° C / s). Chikamu chidiki chete cheMg2Si chikamu chinonaya zvishoma nezvishoma, uye tembiricha i360C mushure me90s. Mushure mekutonhora kwemvura, yakawanda yeMg2Si chikamu ichiri mumatrix, uye inopararira uye inonaya mushure mekukwegura, iyo inoita basa rekusimbisa.

3. Mhedziso

Zvakawanikwa kuburikidza nemiedzo kuti kunonoka kudzima kuchakonzera kuoma kwenzvimbo yekudzimisa yakanonoka pamharadzano yenguva dzose yekudzima uye kunonoka kudzima kusvika pekutanga kudzikira uyezve kuwedzera zvishoma kusvika yadzikama.

Kune 6061 aruminiyamu alloy, masimba ekusimba mushure menguva dzose kudzima uye kunonoka kudzima kwe90s i342MPa uye 288MPa zvakateerana, uye simba regoho i315MPa uye 252MPa, ese ari maviri anosangana nesample performance standard.

Kune dunhu rine kuomarara kwakadzikira, kunoderedzwa kubva pa95HB kuenda pa77HB mushure menguva dzose kudzima. Kuita pano zvakare kwakadzikira, kuine simba rekusimba re271MPa uye goho resimba re220MPa.

Kuburikidza nekuongorora kweANSYS, zvakaonekwa kuti chiyero chekutonhodza panzvimbo yakaderera yekushanda mu90s yakanonoka kudzima nzvimbo yakaderera neanenge 3.5 ° C pasekondi, zvichikonzera kusakwana kwakasimba mhinduro yechikamu chekusimbisa Mg2Si chikamu. Zvinoenderana nechinyorwa ichi, zvinogona kuoneka kuti mashandiro engozi nzvimbo inoonekwa munzvimbo yakanonoka yekudzima panosangana nhanho yekudzima uye kunonoka kudzima, uye haisi kure nekusangana, iyo ine yakakosha inotungamira kukosha kwekuchengetwa kunonzwisisika kweextrusion muswe kupera muitiro tsvina.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Aug-28-2024