1.Introduction

Aluminium alloys ane simba repakati anoratidza maitiro akanaka ekugadzirisa, kudzima kunzwisiswa, kuomarara kwemaitiro, uye kushomeka kwekuora. Vanoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana, akadai semagetsi uye emugungwa, kugadzira pombi, tsvimbo, maprofile, uye waya. Parizvino, pane kuwedzera kuri kuda kwe6082 aluminium alloy bars. Kuti tisangane nemusika zvinodiwa uye zvinodiwa nemushandisi, takaita zviyedzo pane akasiyana extrusion kudziyisa maitiro uye ekupedzisira kupisa kupisa kwe6082-T6 mabara. Chinangwa chedu chaive chekuona chirongwa chekurapa kupisa chinogutsa zvinodiwa zvemakinari zvemabhawa aya.

2.Experimental Materials uye Production Process Flow

2.1 Zvishandiso zvekuedza

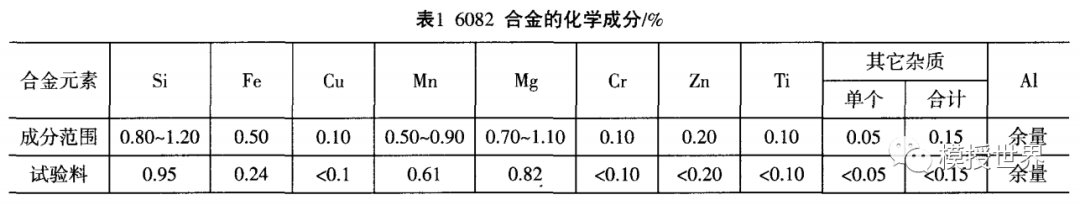

Kukandira ingots yehukuru Ф162 × 500 yakagadzirwa uchishandisa semi-inoenderera mberi yekukanda nzira uye pasi pekurapwa kusina kufanana. Iyo metallurgical quality yeingots yaienderana nekambani yemukati yekutonga tekinoroji zviyero. Iyo kemikari inoumbwa ye6082 alloy inoratidzwa muTafura 1.

2.2 Kuyerera Kwekugadzira

Iwo ekuyedza 6082 mabhawa aive neyakatsanangurwa yeФ14mm. Chigadziko cheextrusion chaive nedhayamita yeF170mm ine 4-hole extrusion design uye extrusion coefficient ye18.5. Iyo chaiyo nzira yekuyerera yaisanganisira kupisa iyo ingot, extrusion, kudzima, kutambanudza kutwasanudza uye sampling, roller kutwasanudza, yekupedzisira kucheka, kuchembera kwekugadzira, kuongororwa kwemhando, uye kuendesa.

3.Kuedza Zvinangwa

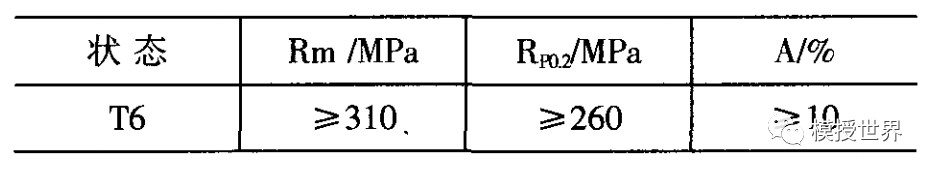

Chinangwa chechidzidzo ichi chaive chekuona iyo extrusion heat treatment process parameters uye ekupedzisira kupisa kupisa parameters inopesvedzera mashandiro e6082-T6 bars, pakupedzisira ichiwana chiyero chekuita zvinodiwa. Zvinoenderana nezviyero, iyo longitudinal mechanical zvivakwa zve6082 alloy inofanirwa kusangana nezvakatsanangurwa muTable 2.

4.Experimental Approach

4.1 Extrusion Heat Treatment Investigation

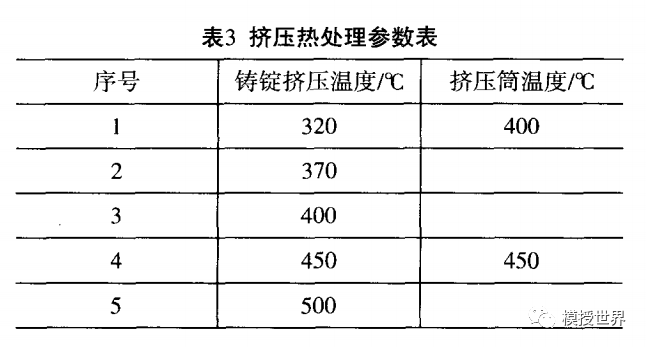

Iyo extrusion kupisa kurapwa kuferefeta kwainyanya kutarisana nemhedzisiro yekukanda ingot extrusion tembiricha uye extrusion mudziyo tembiricha pane mechaniki zvinhu. Iyo chaiyo parameter yakasarudzwa inotsanangurwa muTafura 3.

4.2 Solid Solution uye Kuchembera Heat Treatment Investigation

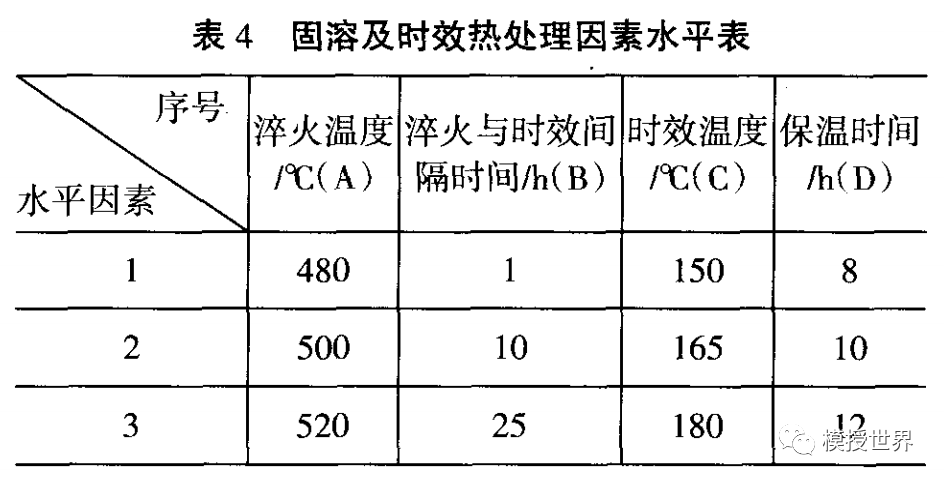

Iyo orthogonal yekuyedza dhizaini yakashandiswa kune yakasimba mhinduro uye kuchembera kupisa kupisa maitiro. Iyo yakasarudzwa factor nhanho inopihwa muTafura 4, ine orthogonal dhizaini tafura inoratidzwa seIJ9(34).

5.Zvigumisiro uye Analysis

5.1 Extrusion Heat Treatment Experiment Results uye Analysis

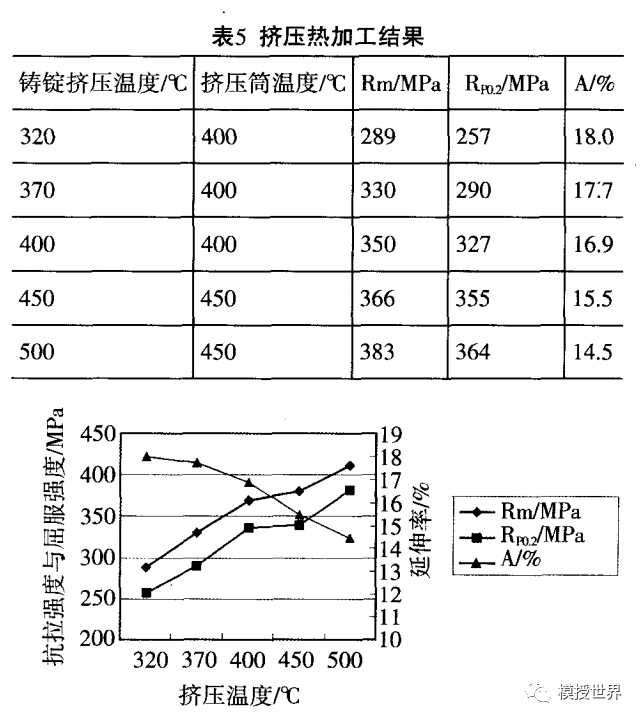

Migumisiro yeextrusion heat treatment experiments inoratidzwa muTebhu 5 uye Mufananidzo 1. Zvipfumbamwe zvienzaniso zvakatorwa kune rimwe boka rimwe nerimwe, uye maitiro avo ekugadzirisa maitiro akatemwa. Kubva pakuongorora metallographic uye kuumbwa kwemakemikari, chirongwa chekurapa kwekupisa chakasimbiswa: kudzima pa 520 ° C kwemaminitsi makumi mana uye kukwegura pa165 ° C kwemaawa gumi nemaviri. Kubva Tafura 5 uye Figure 1, zvinogona kucherechedzwa kuti sezvo kukanda ingot extrusion tembiricha uye extrusion mudziyo tembiricha yakawedzera, zvose tensile simba uye goho simba zvishoma nezvishoma. Mhedzisiro yakanakisa yakawanikwa pakupisa kwe450-500 ° C uye tembiricha yekupisa ye450 ° C, iyo yakasangana nezvinodiwa. Izvi zvakakonzerwa nemhedzisiro yekushanda kunotonhora kuomarara pakudzikira kwakadzikira, zvichikonzera kutsemuka kwemuganho wezviyo uye kuwedzera kuomarara kwekugadzirisa pakati peA1 neMn panguva yekupisa kusati kwadzima, zvichikonzera kudzoreredza. Sezvo tembiricha yeextrusion yakawedzera, iyo yekupedzisira simba Rm yechigadzirwa yakavandudzwa zvakanyanya. Kana tembiricha yemidziyo yeextrusion yaswedera kana kupfuura tembiricha yeingot, deformation isina kuenzana yakadzikira, ichidzikisa kudzika kwemhete dzezviyo uye kuwedzera simba regoho Rm. Saka, inonzwisisika parameters ye extrusion kupisa kurapwa ndeiyi: ingot extrusion tembiricha ye450-500 ° C uye extrusion mudziyo tembiricha ye430-450 ° C.

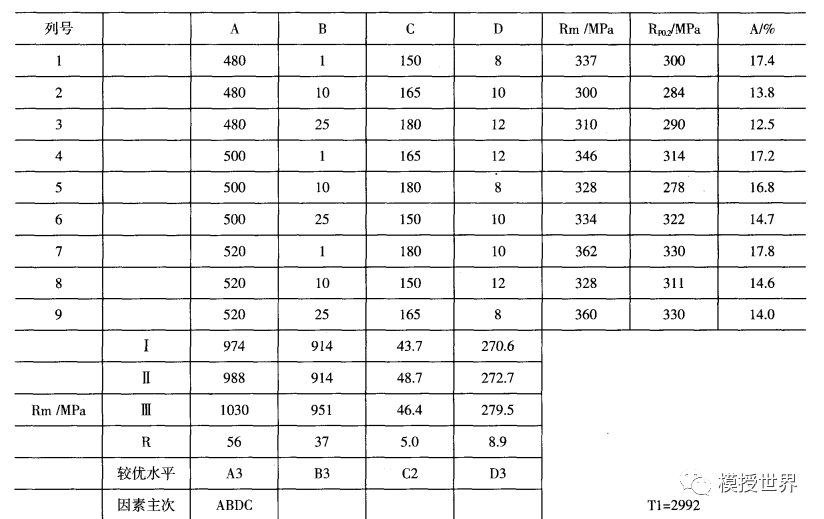

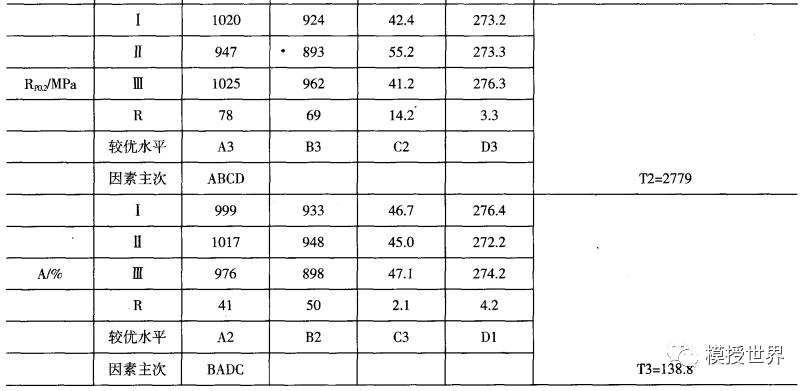

5.2 Solid Solution uye Kuchembera Orthogonal Kuedza Migumisiro uye Analysis

Tafura 6 inoratidza kuti mazinga akakwana ndeaya A3B1C2D3, nekudzima pa520 ° C, tembiricha yekuchembera iri pakati pe165-170 ° C, uye nguva yekuchembera kwemaawa gumi nemaviri, zvichikonzera kusimba kwepamusoro uye plastiki yemabhawa. Iyo yekudzima nzira inoumba supersaturated solid solution. Pakudzika kwekupisa tembiricha, kuwanda kweiyo supersaturated yakasimba mhinduro inoderera, inokanganisa simba. Kudzima tembiricha inotenderedza 520 ° C inosimudzira zvakanyanya mhedzisiro yekudzima-induced yakasimba mhinduro yekusimbisa. Iyo nguva pakati pekudzima uye kuchembera kwekugadzira, kureva, kuchengetedza tembiricha yekamuri, inokanganisa zvakanyanya ma mechanical properties. Izvi zvinonyanya kutaurwa kune tsvimbo dzisina kutambanudzwa mushure mekudzima. Kana nguva iri pakati pekudzima nekuchembera inopfuura 1 awa, simba, kunyanya kusimba kwegoho, rinoderera zvakanyanya.

5.3 Metallographic Microstructure Analysis

High-magnification uye polarized ongororo yakaitwa pamabhawa 6082-T6 patembiricha yakasimba ye520°C uye 530°C. Mapikicha epamusoro-soro anoratidza kunaya kwakafanana kwemukomboni ine mvura zhinji yepasi pechikamu chezvikamu zvakagoverwa zvakaenzana. Polarized light analysis uchishandisa Axiovert200 midziyo yakaratidza mutsauko wakasiyana mumapikicha ezviyo. Nzvimbo yepakati yairatidza zviyo zvidiki uye yunifomu, nepo mipendero yairatidzira imwe recrystallization ine tsanga dzakarebesa. Izvi zvinokonzerwa nekukura kwekristaro nuclei pakupisa kwepamusoro, kuumba hutsinye hwetsono-semvura inonaya.

6.Production Practice Assessment

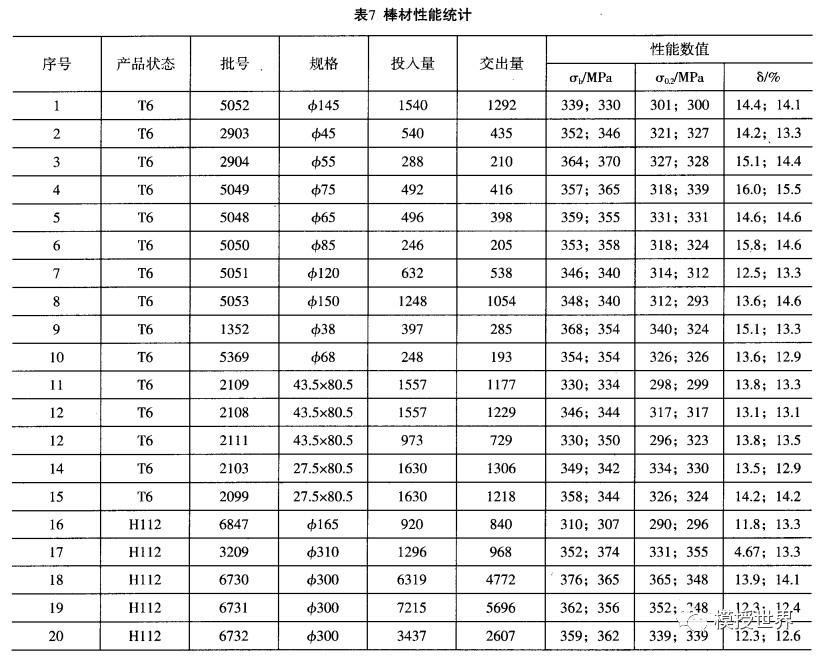

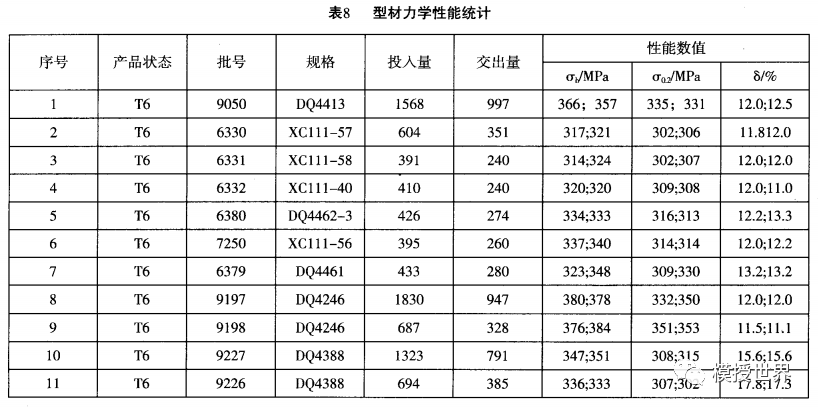

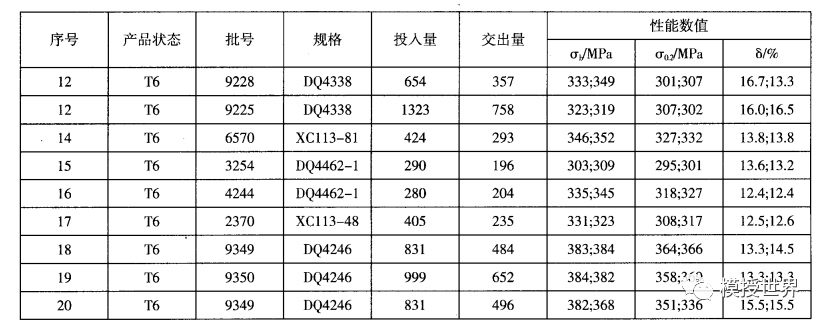

Mukugadzirwa chaiko, manhamba ekuita kwemuchina akaitwa pamabhechi makumi maviri emabhawa uye makumi maviri mabheti emaprofile. Zvigumisiro zvinoratidzwa muTables 7 uye 8. Mukugadzirwa kwechokwadi, nzira yedu ye extrusion yakaitwa pakupisa kunoguma neT6 state samples, uye kushandiswa kwemagetsi kwakasangana nezvinangwa zvinotarisirwa.

7. Mhedziso

(1) Extrusion heat treatment parameters: Ingots extrusion tembiricha ye450-500 ° C; extrusion mudziyo tembiricha ye430-450°C.

(2) Mhedzisiro yekupedzisira yekupisa kupisa: Optimal solid solid solution tembiricha ye520-530 ° C; kuchembera tembiricha pa 165 ± 5 ° C, nguva yekuchembera kwemaawa gumi nemaviri; nguva pakati pekudzima nekuchembera haifanire kudarika 1 awa.

(3) Kubva pakuongorora kunoshanda, iyo inoshanda yekupisa kupisa kunosanganisira: extrusion tembiricha ye450-530 ° C, extrusion mudziyo tembiricha ye400-450 ° C; yakasimba mhinduro tembiricha ye510-520 ° C; chirongwa chekukwegura che 155-170 ° C kwemaawa gumi nemaviri; hapana muganhu chaiwo wepakati pakati pekudzima nekukwegura. Izvi zvinogona kuiswa mumitemo yekushanda kwemaitiro.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Mar-15-2024