Kana iyo mechanical properties ye extrusions isingatarisirwi, kutarisa kunowanzotarisana nekutanga kuumbwa kwebillet kana extrusion / kukwegura mamiriro. Vashoma vanhu vanobvunza kana homogenization pachayo inogona kunge iri nyaya. Muchokwadi, iyo homogenization nhanho yakakosha pakugadzira emhando yepamusoro extrusions. Kutadza kunyatso kudzora homogenization nhanho inogona kutungamirira kune:

●Kuwedzera kudzvanya

●Kuwedzera kukanganisa

● Streak textures pashure anodizing

●Lower extrusion speed

●Kushaikwa kwemagetsi

Iyo homogenization nhanho ine zvinangwa zviviri zvikuru: kunatsa iron-ine intermetallic komisheni, uye kugoverazve magnesium (Mg) uye silicon (Si). Nokuongorora iyo microstructure yebillet isati yasvika uye mushure mekuita homogenization, munhu anogona kufanotaura kana billet ichaita zvakanaka panguva ye extrusion.

Mhedzisiro yeBillet Homogenization paKuomesa

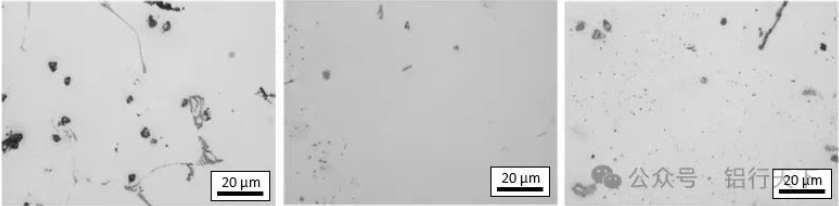

Mu6XXX extrusions, simba rinobva kuMg- uye Si-rich zvikamu zvakaumbwa panguva yekukwegura. Kugona kuumba nhanho idzi kunoenderana nekuisa zvinhu mumhinduro yakasimba kusati kwatanga kuchembera. Kuti Mg neSi zvizopedzisira zvave chikamu chemhinduro yakasimba, simbi inofanirwa kudzimwa nekukurumidza kubva pamusoro pe530 ° C. Patembiricha pamusoro peiyi poindi, Mg uye Si zvinonyungudika kuita aluminium. Zvisinei, panguva yeextrusion, simbi inongoramba iri pamusoro peiyi tembiricha kwenguva pfupi. Kuve nechokwadi chekuti Mg uye Si inonyungudika, iyo Mg uye Si zvidimbu zvinoda kuve zvidiki. Nehurombo, panguva yekukanda, Mg uye Si inonaya seyakakura Mg₂Si blocks (Fig. 1a).

Yakajairika homogenization kutenderera kwe6060 billets ndeye 560 °C kwemaawa maviri. Munguva iyi, sezvo billet inogara pamusoro pe530 ° C kwenguva yakareba, Mg₂Si inonyungudika. Pakutonhora, inonaya zvakare mukugovera kwakanyanya (Fig. 1c). Kana tembiricha yehomogenization isina kukwira zvakakwana, kana kuti nguva ipfupi, mamwe maMg₂Si zvidimbu zvakakura zvinosara. Kana izvi zvikaitika, mhinduro yakasimba mushure me extrusion ine mashoma Mg uye Si, zvichiita kuti zvisaite kuumba yakakwira density yekuomesa precipitates-zvichitungamira kukudzikisira michina zvinhu.

Fig. 1. Optical micrographs of polished and 2% HF-etched 6060 billets: (a) as-cast, (b) partially homogenized, (c) zvizere homogenized.

Basa reHomogenization pane Iron-ine Intermetallics

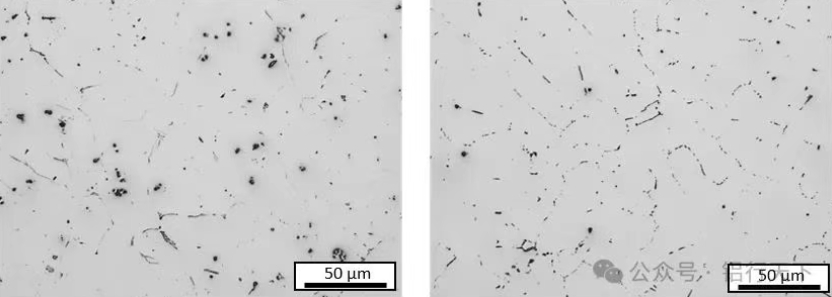

Iron (Fe) ine simba guru pakuputsika kuoma pane simba. Mu6XXX alloys, Fe phases inowanzoita β-phase (Al₅(FeMn)Si kana Al₈.₉(FeMn)₂Si₂) panguva yekukanda. Izvi zvikamu zvakakura, angular, uye zvinokanganisa extrusion (yakasimbiswa muFig. 2a). Munguva yehomogenization, zvinhu zvinorema (Fe, Mn, etc.) zvinopararira, uye zvikamu zvakakura zvemakona zvinova zviduku uye zvakatenderera (Fig. 2b).

Kubva pamifananidzo yemaziso chete, zvakaoma kusiyanisa zvikamu zvakasiyana-siyana, uye hazvibviri kuverengera zvakavimbika. PaInnoval, tinoyera billet homogenization tichishandisa nzira yedu yemukati yekuona uye kupatsanura (FDC), iyo inopa % α kukosha kwemabhiri. Izvi zvinoita kuti tikwanise kuongorora kunaka kwehomogenization.

Fig. 2. Optical micrographs of billets (a) pamberi uye (b) pashure homogenization.

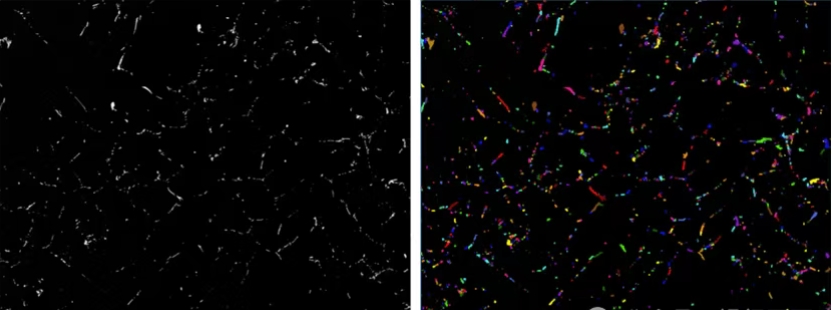

Feature Detection and Classification (FDC) Nzira

Mufananidzo 3a unoratidza sampuli yakakwenenzverwa yakaongororwa nekuongorora electron microscopy (SEM). A greyscale thresholding technique inozoshandiswa kupatsanura uye kuziva intermetallics, inoonekwa yakachena muFig. 3b. Iyi nzira inobvumira kuongororwa kwenzvimbo kusvika 1 mm², zvichireva kuti pamusoro pe1000 maficha emunhu anogona kuongororwa kamwechete.

3

Particle Kuumbwa

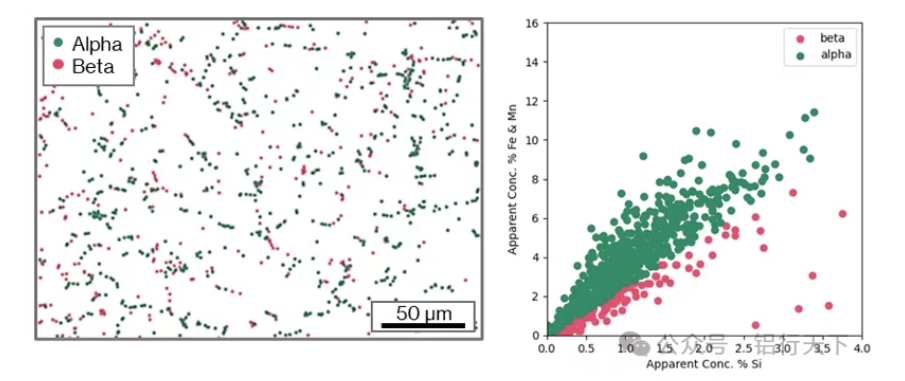

Iyo Innoval system yakashongedzerwa neOxford Instruments Xplore 30 simba-dispersive X-ray (EDX) detector. Izvi zvinobvumira kukurumidza otomatiki kuunganidzwa kweEDX spectra kubva kune yega yega yakacherechedzwa nzvimbo. Kubva pane aya ma spectra, iyo particle inoumbwa inogona kutsanangurwa, uye hukama Fe: Si ratio inferred.

Zvichienderana neMn kana Cr zvemukati meiyo alloy, zvimwe zvinorema zvinhu zvinogona zvakare kuverengerwa. Kune mamwe 6XXX alloys (dzimwe nguva ane akakosha Mn), iyo (Fe + Mn): Si reshiyo inoshandiswa sereferensi. Aya mareshiyo anogona kuenzaniswa neaya anozivikanwa Fe-containing intermetallics.

β-phase (Al₅(FeMn)Si kana Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si ratio ≈ 2. α-phase (Al₁₂(FeMn)₃Si kana Al₈.₃(FeMn) ₉ chiyero zvichienderana ne.Si): Yedu yetsika software inotibvumira kuseta chikumbaridzo uye kuronga chidimbu chimwe nechimwe se α kana β, tobva tapa zvinzvimbo zvavo mukati meiyo microstructure (Fig. 4). Izvi zvinopa inofungidzirwa muzana yekushandurwa α mune homogenized billet.

Fig. 4. (a) Mepu inoratidza α- ne β-classified particles, (b) scatter plot ye (Fe+Mn):Si ratios.

Zvatingaudzwa neData

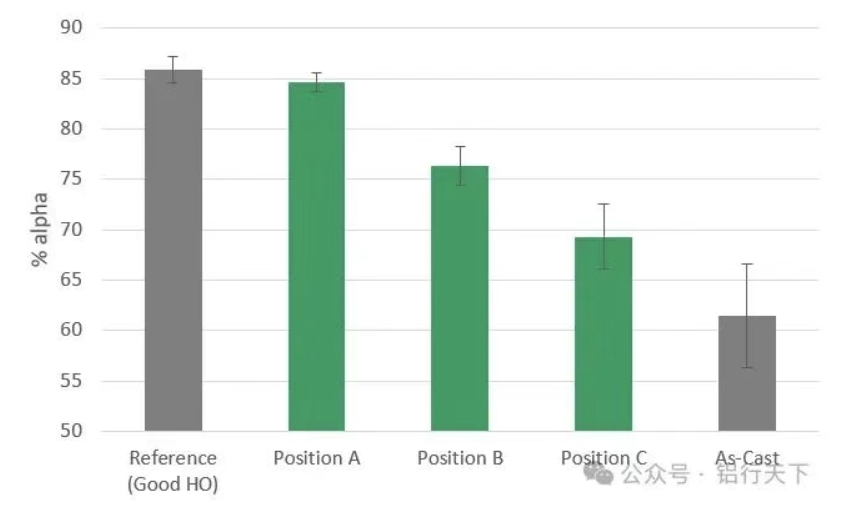

Mufananidzo 5 unoratidza muenzaniso wekuti ruzivo urwu runoshandiswa sei. Muchiitiko ichi, zvigumisiro zvinoratidza kupisa kusina kufanana mukati mechoto chaiyo, kana kuti pamwe tembiricha yekuisa haina kusvika. Kuti unyatso ongorora nyaya dzakadai, zvese zviri zviviri test billet uye referensi mabheti emhando inozivikanwa inodiwa. Pasina izvi, iyo inotarisirwa % α mutsara weiyo alloy kuumbwa hakugone kusimbiswa.

Fig. 5. Kuenzanisa kwe% α muzvikamu zvakasiyana-siyana zvehuto husina kunaka hunoita homogenization.

Nguva yekutumira: Aug-30-2025