Iyo tensile bvunzo yesimba inonyanya kushandiswa kuona kugona kwesimbi zvinhu kuramba kukuvara panguva yekutambanudza maitiro, uye ndeimwe yeakakosha zviratidzo zvekuongorora ma mechanic zvimiro zvezvinhu.

1. Tensile bvunzo

Iyo tensile bvunzo yakavakirwa pamisimboti yekutanga yemidziyo mechanics. Nekuisa mutoro unorema kune sampuli yezvinhu pasi pemamwe mamiriro, zvinokonzeresa deformation kusvika sampu yatyoka. Munguva yekuedzwa, deformation yemuenzaniso wekuedza pasi pemitoro yakasiyana-siyana uye mutoro wepamusoro apo sampuli inoputika yakanyorwa, kuitira kuverenga simba regoho, simba rekusimba uye zvimwe zviratidzo zvekushanda zvezvinhu.

Kushungurudzika σ = F/A

σ ndiyo simba rekusimba (MPa)

F ndiyo inorema mutoro (N)

A ndiyo mhiri-chikamu nzvimbo yemuenzaniso

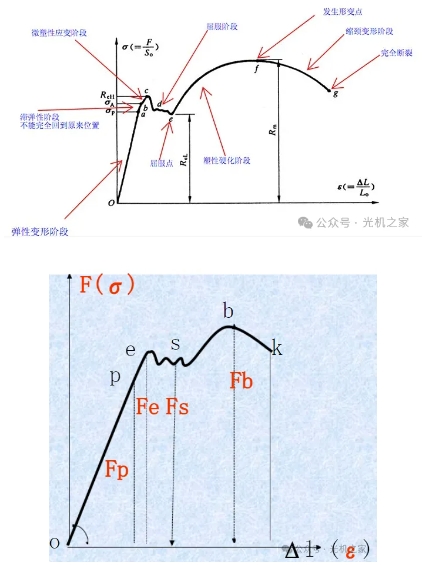

2. Tensile curve

Kuongororwa kwematanho akati wandei ekutambanudza maitiro:

a. Muchikamu cheOP chine mutoro mudiki, kurebesa kuri muhukama hwemutsara nemutoro, uye Fp ndiyo yakanyanya kuremerwa kuchengetedza mutsara wakatwasuka.

b. Mushure mekunge mutoro wapfuura Fp, iyo tensile curve inotanga kutora hukama husina mutsara. Sample inopinda padanho rekutanga deformation, uye mutoro unobviswa, uye sampu inogona kudzokera kune yayo yekutanga uye elastically deform.

c. Mushure mokunge mutoro unopfuura Fe, mutoro wacho unobviswa, chikamu chekugadzirisa chinodzorerwa, uye chikamu chekugadzirisa kwakasara kunochengetwa, iyo inonzi plastiki deformation. Fe inonzi elastic limit.

d. Kana mutoro ukawedzera, iyo tensile curve inoratidza sawtooth. Kana mutoro ukasawedzera kana kuderera, chiitiko chekuenderera mberi kwekuwedzera kwemuenzaniso wekuyedza kunonzi kuburitsa. Mushure mokubereka, sampuli inotanga kupinda pachena plastiki deformation.

e. Mushure mokubereka, muenzaniso unoratidza kuwedzera kwekugadzirisa deformation, kushanda kuoma uye kusimbisa deformation. Kana mutoro uchisvika paFb, chikamu chimwechete chemuenzaniso chinoderera zvakanyanya. Fb ndiyo muganhu wesimba.

f. Iyo shrinkage phenomenon inotungamira mukudzikira kwekutakura kugona kwemuenzaniso. Kana mutoro uchisvika Fk, sampuli inoputsika. Uku kunonzi kutsemuka mutoro.

Goho Simba

Goho simba ndiyo yakanyanya kushushikana kukosha iyo simbi zvinhu inogona kumira kubva pakutanga kwepurasitiki deformation kusvika kupedzisa kuputsika kana ichiiswa kunze kwesimba. Kukosha uku kunoratidza iyo yakakosha poindi iyo zvinhu zvinoshanduka kubva kune elastic deformation nhanho kuenda kune epurasitiki deformation nhanho.

Classification

Upper goho simba: inoreva kunyanya kushushikana kwemuenzaniso simba risati radonha kekutanga kana kubereka kuchiitika.

Kuderera kwegoho simba: zvinoreva kushomeka kwekushushikana muchikamu chegoho kana yekutanga mhedzisiro inoregeredzwa. Sezvo kukosha kweiyo yakaderera goho poindi yakagadzikana, inowanzoshandiswa sechiratidzo chekupokana kwezvinhu, kunonzi goho point kana goho simba.

Calculation formula

Nokuda kwesimba repamusoro regoho: R = F / Sₒ, apo F ndiyo inonyanya kusimba simba risati radonha kekutanga muchikamu chegoho, uye S- ndiyo yepakutanga-chikamu chechikamu chemuenzaniso.

Nekuda kwesimba regoho rakaderera: R = F / Sₒ, uko F iri iyo shoma simba F achiregeredza yekutanga mhedzisiro mhedzisiro, uye Sₒ ndiyo yepakutanga-chikamu chikamu chechikamu chemuenzaniso.

Unit

Chiyero chekusimba kwegoho chinowanzonzi MPa (megapascal) kana N/mm² (Newton per square millimeter).

Muenzaniso

Tora yakaderera kabhoni simbi semuenzaniso, goho rayo rinowanzoita 207MPa. Kana yaiswa pasi pesimba rekunze rakakura kupfuura muganhu uyu, yakaderera kabhoni simbi inoburitsa zvachose deformation uye haigone kudzoserwa; kana yaiswa pasi pesimba rekunze risingasviki muganhu uyu, low carbon steel inogona kudzokera kumamiriro ayo epakutanga.

Kusimba kwegoho chimwe chezviratidzo zvakakosha zvekuongorora michina yemidziyo yesimbi. Inoratidza kugona kwemidziyo kuramba deformation yepurasitiki kana ichiiswa kune ekunze masimba.

Kusimba simba

Kusimba kwesimba ndiko kugona kwechinhu kurwisa kukuvadzwa pasi pemutoro unorema, uyo unonyatso kuratidzwa seyakanyanya kushushikana kukosha iyo chinhu chinogona kumira panguva yekusimba. Kana iyo tensile kushushikana pachinhu ichipfuura simba rayo rekusimba, zvinhu zvacho zvinozoita deformation yepurasitiki kana kutyoka.

Calculation formula

Iyo yekuverenga fomula yekusimba simba (σt) ndeiyi:

σt = F / A

Ipo F ndiyo yakanyanya kusimba simba (Newton, N) iyo sampuli inogona kumira isati yatyoka, uye A ndiyo yepakutanga-yakachinjika nzvimbo yemuenzaniso (square millimeter, mm²).

Unit

Chiyero chekusimba kwesimba kazhinji MPa (megapascal) kana N/mm² (Newton per square millimeter). 1 MPa yakaenzana ne1,000,000 Newtons per square metre, iyo yakaenzana ne1 N/mm².

Kufurira zvinhu

Kusimba kwesimba kunobatwa nezvinhu zvakawanda, zvinosanganisira makemikari anoumbwa, microstructure, kupisa kupisa nzira, nzira yekugadzirisa, etc. Zvinhu zvakasiyana-siyana zvine simba rakasiyana-siyana, saka mukushanda kwekushanda, zvakakosha kusarudza zvinhu zvakakodzera zvichienderana nemagetsi ezvigadzirwa.

Kushanda kunoshanda

Kusimba kwesimba ndiyo yakakosha parameter mumunda wezvekushandisa sainzi uye engineering, uye inowanzoshandiswa kuongorora michina yezvigadzirwa. Panyaya yekugadzirwa kwemaitiro, kusarudzwa kwezvinhu, kuongororwa kwekuchengetedza, nezvimwewo, kusimba kwesimba chinhu chinofanira kutariswa. Semuenzaniso, mukugadzira engineering, kusimba kwekusimba kwesimbi chinhu chakakosha pakuona kana ichigona kumira mitoro; mumunda we aerospace, simba rekusimba rezviyero zvisinganzwisisiki uye yakakwirira-simba ndiyo kiyi yekuvimbisa kuchengetedzwa kwendege.

Kuneta simba:

Metal fatigue inoreva nzira iyo zvinhu uye zvikamu zvishoma nezvishoma zvinogadzira kukuvara kwechigarire kunowedzera munzvimbo imwe kana akati wandei pasi pekunetseka kwecyclic kana cyclic strain, uye kutsemuka kana kungoerekana kutsemuka kwakazara kunoitika mushure meimwe nhamba yekutenderera.

Features

Kamwe kamwe munguva: Metal kuneta kukundikana kunowanzoitika kamwe kamwe munguva pfupi pasina zviratidzo zviri pachena.

Locality in position: Kuneta kukundikana kunowanzoitika munzvimbo dzemunharaunda umo kushushikana kwakanyanya.

Sensitivity kune zvakatipoteredza uye hurema: Metal kuneta inotarisisa zvakanyanya kune zvakatipoteredza uye zvidiki zvirema mukati mechinhu, izvo zvinogona kukurumidza kuita kuneta.

Kufurira zvinhu

Stress amplitude: Hukuru hwekushushikana hunokanganisa zvakananga hupenyu hwekuneta kwesimbi.

Avhareji yekushungurudzika ukuru: Kunyanya kushushikana kweavhareji, kupfupika kwehupenyu hwekuneta kwesimbi.

Huwandu hwematenderedzwa: Iyo nguva zhinji iyo simbi iri pasi pe cyclic kushushikana kana kuomerwa, zvakanyanya kukomba kuunganidzwa kwekukuvara kwekuneta.

Kudzivirira matanho

Natsiridza kusarudzwa kwezvinhu: Sarudza zvinhu zvine mwero wekuneta zvakanyanya.

Kuderedza kushushikana mupfungwa: Deredza kushushikana mupfungwa kuburikidza nemagadzirirwo emagadzirirwo kana nzira dzekugadzirisa, sekushandisa yakatenderedzwa makona shanduko, kuwedzera kuyambuka-chikamu mativi, nezvimwe.

Kurapa kwepamusoro: Kupukuta, kupfapfaidza, nezvimwewo pamusoro pesimbi kuti kuderedze kuremara kwepamusoro uye kuvandudza simba rekuneta.

Kuongorora uye kugadzirisa: Gara uchiongorora zvikamu zvesimbi kuti uone nekukurumidza uye kugadzirisa kukanganisa kwakadai sekutsemuka; chengetedza mativi anowanzoita kuneta, sekutsiva zvidimbu zvakasakara uye kusimbisa zvinongedzo zvisina simba.

Metal fatigue yakajairika simbi kukundikana modhi, iyo inoratidzirwa nekukasira, nzvimbo uye kunzwa kune zvakatipoteredza. Stress amplitude, avhareji yekushushikana ukuru uye huwandu hwematenderedzwa ndizvo zvinhu zvikuru zvinokanganisa kuneta kwesimbi.

SN curve: inotsanangura hupenyu hwekuneta kwezvinhu zviri pasi pemazinga akasiyana ekushushikana, apo S inomiririra kushushikana uye N inomiririra nhamba yekutenderera kwekunetseka.

Kuneta simba coefficient formula:

(Kf = Ka \cdot Kb \cdot Kc \cdot Kd \cdot Ke)

Ipo (Ka) ndiyo inotakura zvinhu, (Kb) ndiyo saizi factor, (Kc) ndiyo tembiricha chinhu, (Kd) ndiyo yemhando yepamusoro, uye (Ke) ndiyo yakavimbika chinhu.

SN curve mathematical expression:

(\ sigma^m N = C)

Iko (\ sigma) kune kushushikana, N ndiyo nhamba yekutenderera kwekushushikana, uye m uye C zvinhu zvinogara zviripo.

Matanho ekuverenga

Sarudza zvinhu zvinoramba zviripo:

Sarudza kukosha kwem uye C kuburikidza nekuedza kana nekutaura kune akakodzera mabhuku.

Sarudza iyo inokonzera kushungurudzika: Funga nezvechimiro chaicho uye ukuru hwechikamu, pamwe chete nekushungurudzika kunokonzerwa nemafillet, keyways, nezvimwewo, kuti uone kushushikana kwekunetseka K. Verenga kuneta simba: Maererano neSN curve uye kushushikana kwepfungwa, kusanganiswa nehupenyu hwekugadzira uye kushanda kwekunetseka kwechikamu chechikamu, kuverenga simba rekuneta.

2. Plasticity:

Plasticity (Plasticity) zvinoreva pfuma yechinhu chinoti kana chaiswa pasimba rekunze, chinoburitsa deformation yekusingaperi pasina kutyoka kana simba rekunze richidarika muganhu wayo. Iyi deformation haidzokerike, uye zvinhu hazvidzoke kune chimiro chayo chepakutanga kunyangwe simba rekunze rikabviswa.

Plasticity index uye maitiro ayo ekuverenga

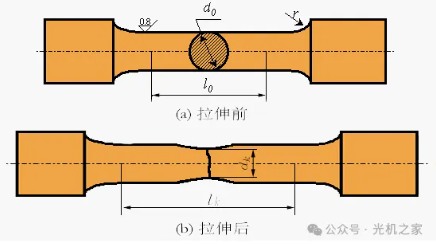

Elongation (δ)

Tsanangudzo: Elongation iperesenti yehuwandu hwekuchinja kwegeji chikamu mushure memuenzaniso wakaputsika kusvika pakureba kwekutanga kwegeji.

Fomula: δ = (L1 – L0) / L0 × 100%

Iko L0 ndiyo yepakutanga geji kureba kwemuenzaniso;

L1 ndiyo urefu hwejeji mushure mekunge muenzaniso waputswa.

Segmental kuderedza (Ψ)

Tsanangudzo: The segmental reduction ndiyo yeperesenti yekuderedzwa kwepamusoro-soro munzvimbo yekuchinjika pamutsipa wemutsipa mushure mekunge muenzaniso wacho waputsika kune yepakutanga-chikamu chechikamu.

Fomula: Ψ = (F0 – F1) / F0 × 100%

Iko F0 ndiyo yepakutanga-chikamu-chikamu nzvimbo yemuenzaniso;

F1 inzvimbo yakachinjika pamutsipa mushure mekunge muenzaniso waputswa.

3. Kuoma

Metal kuomarara indekisi yemidziyo yekuyera kuoma kwezvinhu zvesimbi. Inoratidza kukwanisa kupikisa deformation muhuwandu hwemunharaunda panzvimbo yesimbi.

Kuronga uye kumiririra kwesimbi yakaoma

Metal kuomarara ine akasiyana siyana ekuisa uye nzira dzekumiririra zvinoenderana neakasiyana nzira dzekuedza. Zvikuru zvinosanganisira zvinotevera:

Brinell kuoma (HB):

Chiyero chekushandisa: Inowanzo shandiswa kana zvinhu zvakapfava, senge asiri-ferrous simbi, simbi isati yaitwa kupisa kana mushure mekuvhara.

Test musimboti: Nehumwe saizi yemuyedzo wemuyedzo, bhora rakaoma resimbi kana carbide bhora reimwe dhayamita rinotsikirirwa mukati mesimbi kuti iedzwe, uye mutoro unoburutswa mushure menguva yakatarwa, uye dhayamita yeiyo indentation pamusoro pekuedzwa kunoyerwa.

Calculation formula: Iyo Brinell kuomarara kukosha ndiyo quotient inowanikwa nekupatsanura mutoro nedenderedzwa repamusoro penzvimbo yekumisikidza.

Rockwell kuoma (HR):

Chiyero chekushandisa: Inowanzo shandiswa kune zvigadzirwa zvine kuomarara kwepamusoro, sekuoma mushure mekupisa kupisa.

Test musimboti: Zvakafanana Brinell kuoma, asi kushandisa akasiyana probes (dhaimondi) uye akasiyana maverengero nzira.

Mhando: Zvichienderana nekushandiswa, kune HRC (yepamusoro kuomarara zvinhu), HRA, HRB nemamwe marudzi.

Vickers kuoma (HV):

Chiyero chekushandisa: Inokodzera kuongororwa kwemicroscope.

Test musimboti: Dzvanya pamusoro pezvinhu zvine mutoro usingasviki 120kg uye dhaimondi square cone indenter ine vertex angle ye136 °, uye patsanura iyo nzvimbo yepasi pegomba remukati nekukosha kwemutoro kuti uwane kukosha kweVickers.

Leeb kuoma (HL):

Zvimiro: Inotakurika kuomarara tester, iri nyore kuyera.

Test musimboti: Shandisa kubhuroka kunogadzirwa neanokanganisa bhora musoro mushure mekukanganisa kuoma kwepasi, uye verenga kuomarara nereshiyo yekumhanya kwepanch pa 1mm kubva kumuenzaniso wepasi kusvika pakumhanyisa kumhanya.

Nguva yekutumira: Sep-25-2024