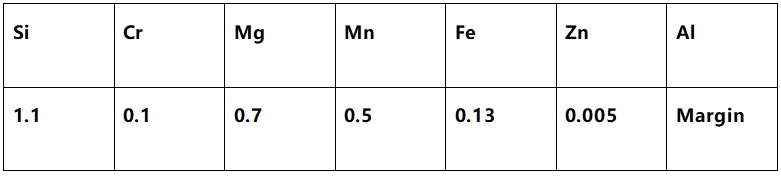

1. Alloy kuumbwa

2. Homogenization Process

390 ℃ x insulation ye 1.0h + 575℃ x insulation ye8h, mhepo ine simba inotonhora kusvika 200℃ uyezve kutonhora kwemvura.

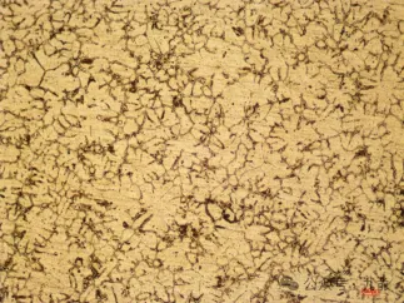

3. Metallographic Structure

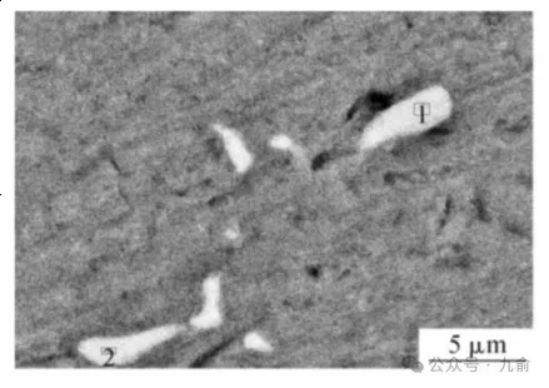

Mufananidzo 1 Metallographic chimiro chepakati che6082 alloy ingot, yakamiswa naKeller reagent, ine dendrites akagadzirwa zvakanaka.

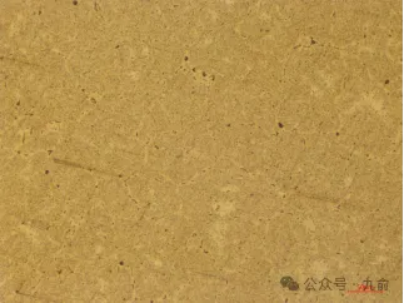

Mufananidzo 2 Metallographic chimiro chepakati che6082 alloy ingot, yakamiswa neKeller reagent, uye chimiro mushure memhinduro yakasimba.

4. Mhedzisiro ye homogenization kupisa kurapwa pane alloy chimiro

4.1 Sezvinoratidzwa muMufananidzo 1, iyo alloy ine dendrites yakanyatsogadzirwa munzvimbo yakakandwa, uye kune nhamba huru ye network non-equilibrium precipitation phases pamiganhu yezviyo.

4.2 Sezvo kunyunguduka kwezvinhu zvakasiyana-siyana zvakasiyana kana alloy ichisimbisa, iyi sequential solidification phenomenon inotungamirira kusaenzana solute kuumbwa mukati mekristaro, iyo inonyatsoratidzwa mukugadzirwa kwenhamba yakawanda yezvikamu zvekunaya kwetiweki pamiganhu yezviyo.

4.3 Mu microstructure mushure mekurapa homogenization (Mufananidzo 2), chiyero chezvikamu zvemvura pamiganhu yezviyo zvakaderedzwa zvikuru, uye kukura kwezviyo kunowedzera synchronously. Izvi zvinodaro nekuti kupararira kwemaatomu kunokwidziridzwa pasi pekupisa kwakanyanya, kubviswa kwekusarura uye kusaenzana kwechikamu chekuparara kunoitika muingot, uye mambure etiweki pamiganhu yezviyo anonyungudika zvishoma.

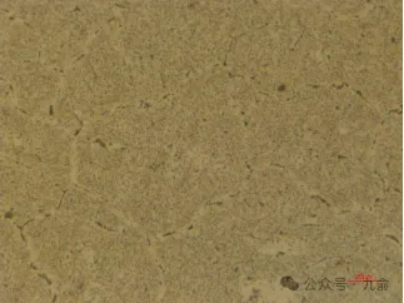

4.4 Kuburikidza neSEM kuongororwa, sezvakaratidzwa muFIG3, zvikamu zvakasiyana-siyana zvechikamu chakakonzerwa zvakasarudzwa kuti zviongorore EDS, zvichisimbisa kuti chikamu chakakonzerwa chaiva Al (MnFe) Si phase.

4.5 Munguva yekukanda alloy, huwandu hukuru hweMn-ine mvura inonaya inoumbwa, uye chikamu chayo chinochengetwa mune supersaturated yakasimba mhinduro. Mushure mekupisa kwepamusoro uye kwenguva yakareba homogenization kurapwa, Mn supersaturated mu matrix precipitates nenzira yeMn-containing compounds, iyo inoratidzwa senhamba yakawanda yakapararira Mn-ine makemikari ekuparara kwezvikamu zvakakonzerwa mukristaro (Mufananidzo 2).

4.6 Sezvo chikamu chemvura chine Mn element, ine kugadzikana kwakanaka kwekupisa. Nekuwedzera kweatomic diffusion, iyo Al (MnFe) Si chikamu zvidimbu zvishoma nezvishoma zvinoratidza spheroidization maitiro.

Fig.3 Al(MnFe)Si chikamu mu6082 alloy

5. Mhedzisiro yemhinduro yekuchembera system pane mechanical properties

Mushure mekuita homogenization, iyo network yakawedzera chikamu chepakutanga pamuganho wezviyo we6082 alloy inonyungudika, iyo inogona kuvandudza yakazara ma mechanical zvimiro zvesample. Panguva imwecheteyo, iyo yakagadzikana inodzivirira kupisa chikamu cheAl(MnFe)Si chikamu chinowedzerwa spheroidized, iyo inogona kuita zvirinani kutsemuka. Izvi zvinoratidza kuti kushanda kwakazara kwezvinhu kuchavandudzwa mushure mekuita homogenization kupisa kurapwa.

6. Mhedziso

6.1 Iyo 6082 aluminium alloy ingot ine dendrites yakanyatsogadzirwa uye nhamba huru yetiweki isina-equilibrium precipitation phases pamiganhu yezviyo.

6.2 Mushure mokurapa homogenization, microscopic yekucherechedza yakaratidza kuti huwandu hwezvikamu zvemvura zvakaderedzwa zvakanyanya, uye kukura kwezviyo kwakawedzera synchronously. Kubviswa kwekusarura uye kusaenzana kwechikamu chekuparara kwakaitika muingot, uye mambure emagetsi pamiganhu yezviyo akanyungudika zvishoma.

6.3 Kana uchikanda 6082 alloy, Al(MnFe)Si nhanho yekunaya inogadzirwa. Ichi chikamu chekunaya chine Mn element uye ine yakanaka kugadzikana kwekupisa. Sezvo iyo homogenization inoenderera mberi, iyo precipitation phase particles zvishoma nezvishoma inoratidza spheroidization maitiro. Iyi Mn-ine makomisheni zvimedu zvakaparadzirwa zvakafanana uye zvinonaya mukristaro.

6.4 Mushure mokurapa homogenization, kuparara kweiyo network precipitated phase kunoratidza kuti kushanda kwese kweingot yose kunovandudzwa mushure mekuita homogenization kupisa kupisa.

Nguva yekutumira: Jun-08-2025