6063 aruminiyamu alloy ndeye yakaderera-alloyed Al-Mg-Si akatevedzana kupisa-inorapwa aluminium alloy. Iyo ine yakanakisa extrusion molding performance, yakanaka corrosion resistance uye yakazara ma mechanical properties. Iyo zvakare inoshandiswa zvakanyanya muindasitiri yemotokari nekuda kweiyo nyore oxidation coloring. Nekuwedzera kwemaitiro emotokari dzakareruka, kushandiswa kwe6063 aluminium alloy extrusion zvinhu muindasitiri yemotokari kwakawedzera zvakare.

Iyo microstructure uye zvivakwa zve extruded zvinhu zvinokanganiswa neyakasanganiswa mhedzisiro ye extrusion kumhanya, extrusion tembiricha uye extrusion ratio. Pakati pavo, iyo extrusion reshiyo inonyanya kutsanangurwa neiyo extrusion kudzvanywa, kugona kugadzira uye zvigadzirwa zvekugadzira. Kana iyo extrusion reshiyo idiki, iyo alloy deformation idiki uye iyo microstructure kunatswa haisi pachena; kuwedzera iyo extrusion reshiyo inogona kukwenenzvera zviyo, kuputsa chikamu chechipiri chakaomarara, kuwana yunifomu microstructure, uye kugadzirisa michina yealloy.

6061 uye 6063 aruminiyamu alloys anoenda kune simba recrystallization panguva yeextrusion process. Kana tembiricha yeextrusion ichigara, sekuwedzera kwekuwedzera, saizi yezviyo inoderera, chikamu chekusimbisa chinoparadzirwa zvakanaka, uye kusimba kwesimba uye elongation yealloy inowedzera zvinoenderana; zvisinei, sezvo chiyero chekuwedzera chinowedzera, simba rekuwedzera rinodiwa kuti riwedzere kuwedzera, zvichiita kuti kupisa kwakanyanya, zvichiita kuti kupisa kwemukati kwealloy kuwedzere, uye kushanda kwechigadzirwa kuderera. Ichi kuyedza chinoongorora mhedzisiro yeextrusion reshiyo, kunyanya yakakura extrusion reshiyo, pane iyo microstructure uye michina zvimiro zve6063 aluminium alloy.

1 Kuedza zvinhu uye nzira

Nyaya yekuedza ndeye 6063 aluminium alloy, uye chemikemikari inoratidzwa muTebhu 1. Ukuru hwepakutanga hweingot ndeye Φ55 mm × 165 mm, uye inoshandiswa kuva billet extrusion nehukuru hwe Φ50 mm × 150 mm mushure mokurapa homogenization pa 560 ℃ ye6 h. Billet rinopisa kusvika ku470 ℃ uye rinogara richidziya. Preheating tembiricha ye extrusion barrel ndeye 420 ℃, uye preheating tembiricha ye mold i450 ℃. Kana iyo extrusion kumhanya (extrusion tsvimbo inofamba kumhanya) V = 5 mm / s inoramba isina kuchinjika, 5 mapoka eakasiyana extrusion reshiyo bvunzo anoitwa, uye extrusion reshiyo R iri 17 (inoenderana nedhiyabhorosi dhayamita D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), 69 (D = 6 mm).

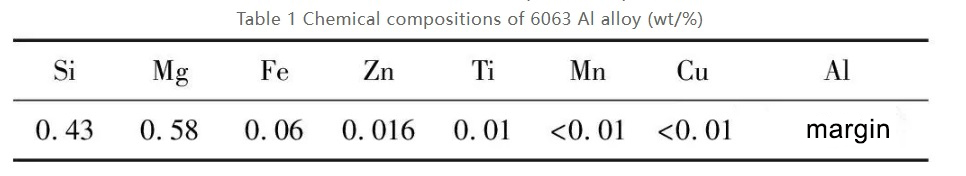

Tafura 1 Kemikari zvinyorwa zve6063 Al alloy (wt/%)

Mushure mekukuya sandpaper uye mechanical polishing, iyo metallographic samples yakaiswa neHF reagent ine vhoriyamu chikamu che40% kweinenge 25 s, uye iyo metallographic chimiro chesamples yakaonekwa pane LEICA-5000 optical microscope. Sampu yekuongorora manyorerwo ane saizi ye10 mm × 10 mm yakachekwa kubva pakati peiyo longitudinal chikamu cheiyo extruded tsvimbo, uye mechanical grinding uye etching yakaitwa kuti ibvise pamusoro pekunetseka kwepamusoro. Nhamba dzisina kukwana dzemapuraneti matatu ekristaro ndege {111}, {200}, uye {220} dzemuenzaniso dzakayerwa neX'Pert Pro MRD X-ray diffraction analyzer yePANalytical Company, uye data yemavara yakagadziriswa nekuongororwa neX'Pert Data View uye X'Pert Texture software.

Iyo yekumisikidza yekumisikidza yeakakandirwa alloy yakatorwa kubva pakati peingot, uye iyo tensile specimen yakatemwa pamwe neiyo extrusion nzira mushure me extrusion. Saizi yenzvimbo yegeji yaive Φ4 mm×28 mm. Muedzo wekusimba wakaitwa pachishandiswa SANS CMT5105 universal material test machine ine tensile rate ye2 mm/min. Avhareji kukosha kweatatu akajairwa emuenzaniso akaverengerwa seyakagadzirwa data data. Kutyoka morphology yezviyero zvekusimba kwakaonekwa pachishandiswa yakaderera-magnification scanning electron microscope (Quanta 2000, FEI, USA).

2 Migumisiro uye nhaurirano

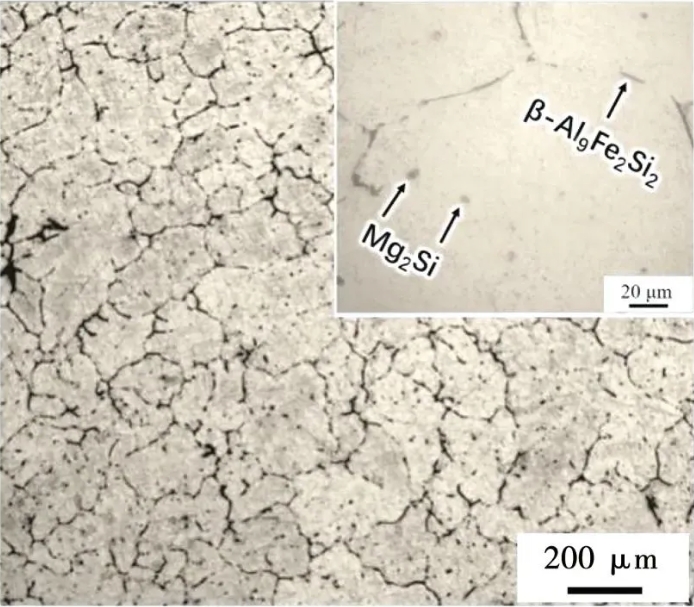

Mufananidzo 1 unoratidza iyo metallographic microstructure yeas-cast 6063 aluminium alloy isati yasvika uye mushure mekuita homogenization kurapwa. Sezvinoratidzwa muMufananidzo 1a, iyo α-Al mbeu mu-as-cast microstructure inosiyana muhukuru, nhamba huru yezvikamu zve reticular β-Al9Fe2Si2 inoungana pamiganhu yezviyo, uye nhamba huru yezvikamu zvegranular Mg2Si zviripo mukati mezviyo. Mushure mekunge ingot yaitwa homogenized pa560 ℃ ye6 h, iyo isiri-equilibrium eutectic phase pakati pealloy dendrites yakanyungudika zvishoma nezvishoma, alloy element yakanyungudika mumatrix, microstructure yaive yunifomu, uye avhareji saizi yezviyo yaive ingangoita 125 μm (Mufananidzo 1b).

Pamberi pehomogenization

Mushure mekuita uniformizing kurapwa pa600 ° C kwemaawa matanhatu

Fig.1 Metallographic chimiro che6063 aruminiyamu alloy pamberi uye mushure mehomogenization kurapwa.

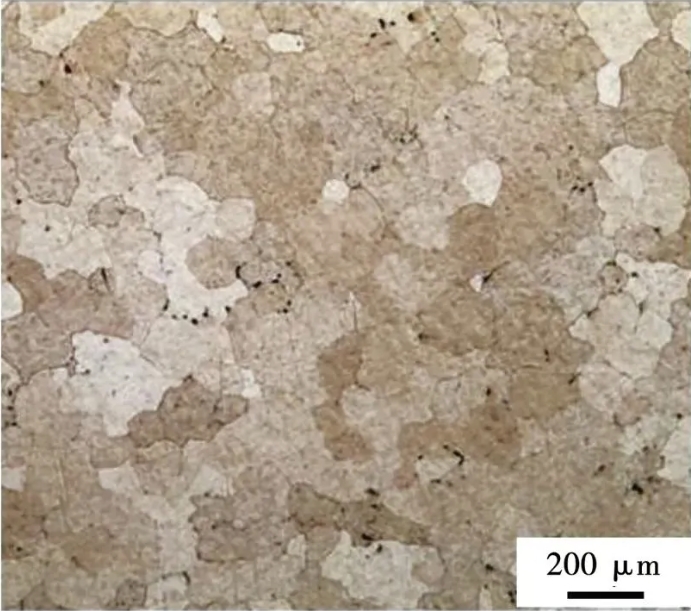

Mufananidzo 2 unoratidza kutaridzika kwe6063 aluminium alloy bars ine akasiyana extrusion ratios. Sezvinoratidzwa mumufananidzo 2, kunaka kwepamusoro kwe6063 aluminium alloy bars yakasimudzwa nemhando dzakasiyana dzeextrusion yakanaka, kunyanya kana iyo extrusion ratio yawedzerwa kusvika 156 (inoenderana nebhawa extrusion outlet yekumhanya ye48 m/min), hapasati pave nekusakwana kwekubuda senge makatsemuka uye kusvuura, mukati meiyo 60 aluminium alloidhi ine yakanaka 60 pfumbu. inopisa extrusion kugadzira kuita pasi pekumhanya kukuru uye yakakura extrusion reshiyo.

Fig.2 Kuonekwa kwe6063 aluminium alloy rods ine akasiyana extrusion ratios.

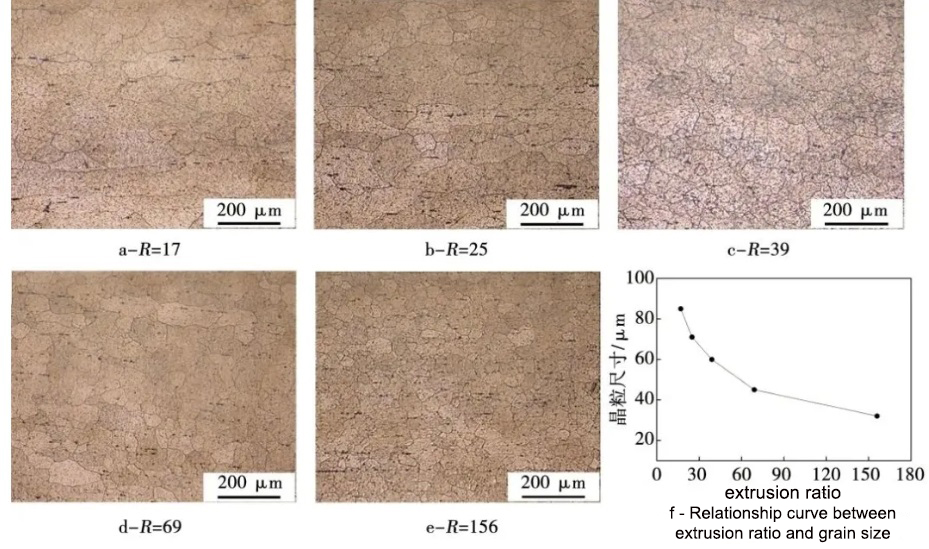

Mufananidzo 3 unoratidza iyo metallographic microstructure yelongitudinal chikamu che6063 aluminium alloy bar ine akasiyana extrusion ratios. Chimiro chezviyo chebhari ine akasiyana extrusion ratios inoratidza madhigirii akasiyana ekurebesa kana kunatsa. Kana iyo extrusion reshiyo iri 17, tsanga dzepakutanga dzakarebeswa pamwe negwara rekuwedzera, richiperekedzwa nekuumbwa kwenhamba shoma yezviyo zvakadzokororwa, asi zviyo zvichiri zvakakora, neavhareji saizi yezviyo inosvika 85 μm (Mufananidzo 3a); apo iyo extrusion reshiyo iri 25, zviyo zvinodhonzwa zvakanyanya kutetepa, nhamba yezviyo zvakadzokororwa inowedzera, uye avhareji saizi yezviyo inoderera kusvika anenge 71 μm (Mufananidzo 3b); apo extrusion reshiyo iri 39, kunze kwenhamba shoma yezviyo zvakaremara, iyo microstructure inonyanya kuumbwa ne equiaxed recrystallized tsanga dze saizi isina kuenzana, ine avhareji yezviyo saizi ye60 μm (Mufananidzo 3c); apo iyo extrusion reshiyo iri 69, iyo dynamic recrystallization process inopedzwa, iyo coarse yepakutanga tsanga yakashandurwa zvachose kuita yakafanana yakarongeka yakagadziridzwa tsanga, uye avhareji saizi yezviyo inonatswa kusvika 41 μm (Mufananidzo 3d); apo chiyero che extrusion chiri 156, nekufambira mberi kwakazara kwesimba recrystallization process, microstructure inowedzera yunifomu, uye saizi yezviyo inonatswa zvakanyanya kusvika 32 μm (Mufananidzo 3e). Nekuwedzera kweyero ye extrusion, iyo dynamic recrystallization process inoenderera zvakanyanya, iyo alloy microstructure inowedzera yunifomu, uye saizi yezviyo inonatswa zvakanyanya (Mufananidzo 3f).

Fig.3 Metallographic chimiro uye saizi yezviyo zvelongitudinal chikamu che6063 aluminium alloy rods ine akasiyana extrusion ratios.

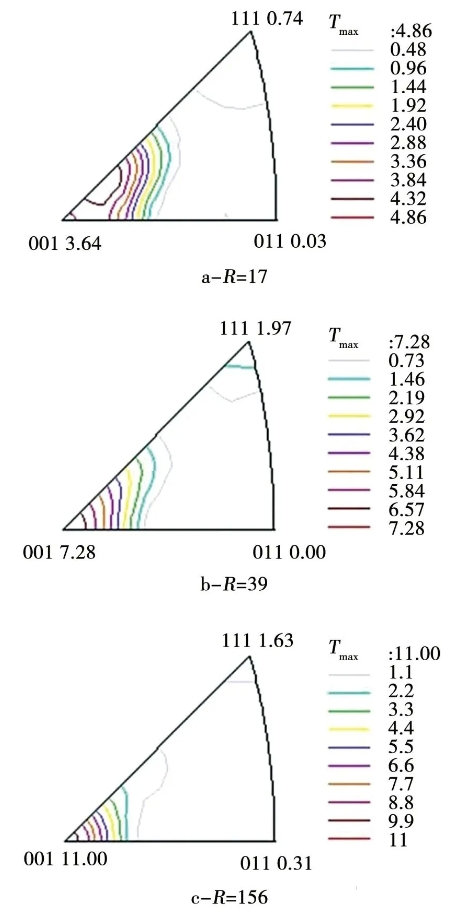

Mufananidzo 4 unoratidza inverse pole manhamba e6063 aluminium alloy bars ane akasiyana extrusion ratios pamwe neextrusion direction. Zvinogona kuoneka kuti mamicrostructures emabhawa alloy ane akasiyana extrusion ratios ese anoburitsa pachena akasarudzika kutaridzika. Kana iyo extrusion ratio iri 17, isina simba <115>+<100> inoumbwa inoumbwa (Mufananidzo 4a); apo chiyero che extrusion chiri 39, zvinyorwa zvinyorwa zvinonyanya kusimba <100> zvinyorwa uye zvishoma zvishoma zvisina simba <115> zvinyorwa (Mufananidzo 4b); kana extrusion reshiyo iri 156, maumbirwo components ari <100> magadzirirwo ane zvikuru akawedzera simba, nepo <115> texture inonyangarika (Figure 4c). Zvidzidzo zvakaratidza kuti face-centered cubic metals inonyanya kuumba <111> uye <100> waya textures panguva extrusion uye kudhirowa. Kamwe maumbirwo akagadzirwa, tembiricha yekamuri yemagetsi zvimiro zvealloy inoratidza pachena anisotropy. Simba rekugadzira rinowedzera nekuwedzera kweyero ye extrusion, zvichiratidza kuti nhamba yezviyo mune imwe crystal direction inofananidzwa ne extrusion direction mu alloy zvishoma nezvishoma inowedzera, uye longitudinal tensile simba re alloy rinowedzera. Nzira dzekusimbisa dze6063 aluminium alloy inopisa extrusion zvinhu zvinosanganisira kusimba kwezviyo zvakanaka, kuparadzanisa kusimba, kusimbiswa kwemavara, etc. Mukati mehutano hwemagadzirirwo emagetsi anoshandiswa muchidzidzo ichi chekuedza, kuwedzera chiyero che extrusion chine simba rinokurudzira pamusoro pemaitiro ekusimbisa pamusoro apa.

Fig.4 Reverse pole dhayagiramu ye6063 aluminium alloy rods ine akasiyana extrusion ratios pamwe neextrusion direction.

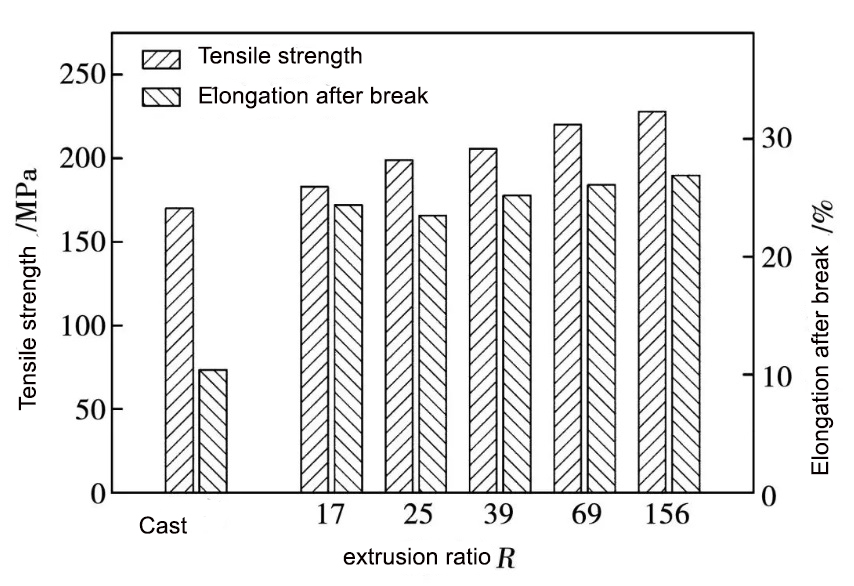

Figure 5 ihistogram yematensile ehupfumi e6063 aruminiyamu alloy mushure mekushanduka kune akasiyana extrusion ratios. Kusimba kwesimba reiyo cast alloy ndeye 170 MPa uye kureba i10.4%. Iko kusimba kwesimba uye kurebesa kweiyo alloy mushure meextrusion inovandudzwa zvakanyanya, uye kusimba kwesimba uye kureba zvishoma nezvishoma kunowedzera nekuwedzera kweiyo extrusion ratio. Kana iyo extrusion reshiyo iri 156, kusimba kwesimba uye kurebesa kwealloy kunosvika pakukosha kwepamusoro, iyo 228 MPa uye 26.9%, zvichiteerana, iyo inenge 34% yakakwirira kudarika simba rekukanda kwekandira uye inenge 158% yakakwirira kudarika kureba. Kusimba kwekusimba kwe6063 aruminiyamu alloy inowanikwa nehombe extrusion reshiyo iri padyo neiyo tensile simba kukosha (240 MPa) yakawanikwa ne4-pass yakaenzana chiteshi angular extrusion (ECAP), iyo yakanyanya kukwirira kupfuura kukosha kwesimba simba (171.1 MPa) inowanikwa ne1-pass ECAP extrusion ye6063 aruminiyamu alloy. Zvinogona kuoneka kuti yakakura extrusion ratio inogona kuvandudza ma mechanical properties yealloy kune imwe nhanho.

Kukwidziridzwa kwema mechanical properties yealloy neextrusion ratio kunonyanya kunobva pakusimbaradza zviyo. Sezvo chiyero che extrusion chinowedzera, zviyo zvinonatswa uye density dislocation inowedzera. Mimwe miganho yezviyo pane imwe nzvimbo inogona kuvhiringidza zvinobudirira kufamba kwekusagadzikana, kusanganiswa nekufamba pamwe chete uye kusungirirwa kwekukanganisa, nekudaro kuvandudza simba reiyo alloy. Iyo yakanakisa zviyo, iyo yakanyanya tortuous miganhu yezviyo, uye deformation yepurasitiki inogona kuparadzirwa mune zvakawanda zviyo, izvo zvisingakodzeri kuumbwa kwekutsemuka, rega kungoita kupararira kwekuputika. Simba rakawanda rinogona kutorwa panguva yekutyoka, nekudaro kuvandudza plastiki yealloy.

Fig.5 Tensile zvimiro zve6063 aluminium alloy mushure mekukanda uye extrusion

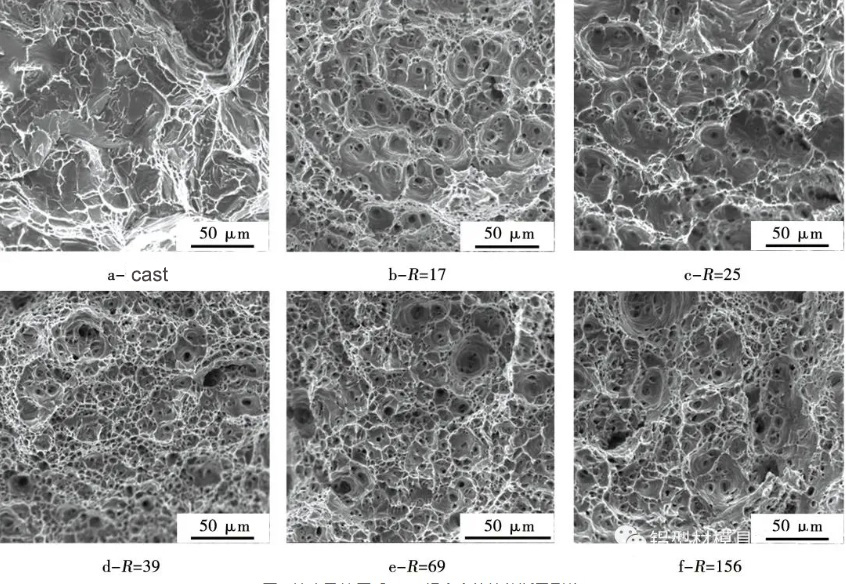

The tensile fracture morphology of the alloy after deformation with different extrusion ratios inoratidzwa muFigure 6. Hapana dimples akawanikwa mune fracture morphology ye-as-cast sample (Mufananidzo 6a), uye kuputsika kwainyanya kuumbwa nenzvimbo dzakadzika uye dzakaputika kumativi, zvichiratidza kuti kuputika kwemaitiro e-tensi fracturettle ye-main fracture yainyanya kuparara. Kuputsika morphology yealloy mushure mokunge extrusion yakashanduka zvikuru, uye kuputsika kunoumbwa nenhamba yakawanda ye equiaxed dimples, zvichiratidza kuti nzira yekuputsika yealloy mushure mokunge extrusion yakashanduka kubva kune brittle fracture kusvika kune ductile fracture. Kana iyo extrusion reshiyo iri diki, ma dimples haana kudzika uye saizi ye dimple yakakura, uye kugovera hakuna kuenzana; sezvo kuwedzera kwekuwedzera kunowedzera, nhamba ye dimples inowedzera, dimple size idiki uye kugoverwa kwakafanana (Mufananidzo 6b ~ f), izvo zvinoreva kuti alloy ine plastiki iri nani, iyo inopindirana ne mechanical properties test results above.

3 Mhedziso

Muchiyedzo ichi, mhedzisiro yeakasiyana extrusion ratios pane microstructure uye zvivakwa zve6063 aruminiyamu alloy zvakaongororwa pasi pemamiriro ekuti saizi yebillet, ingot yekupisa tembiricha uye extrusion kumhanya yakaramba isina kuchinjika. Mhedziso ndeiyi inotevera:

1) Dynamic recrystallization inoitika mu6063 aluminium alloy panguva inopisa extrusion. Nekuwedzera kweyero ye extrusion, zviyo zvinoramba zvichinatswa, uye zviyo zvakatambanudzwa zvichitevedza extrusion direction inoshandurwa kuita equiaxed recrystallized grains, uye simba re <100> wire texture rinoramba richiwedzerwa.

2) Nekuda kwekuita kwekusimbisa zviyo zvakanaka, iyo mechanical properties yealloy inovandudzwa nekuwedzera kweextrusion ratio. Mukati meiyo chiyero cheyedzo paramita, kana extrusion reshiyo iri 156, iyo tensile simba uye elongation yealloy inosvika pahupamhi hwepamusoro hwe228 MPa uye 26.9% zvichiteerana.

Fig.6 Tensile fracture morphologies ye6063 aluminium alloy mushure mekukanda uye extrusion

3) Iyo yekutyoka morphology yeiyo as-cast specimen inoumbwa nenzvimbo dzakati sandara uye kubvarura mipendero. Mushure mekuputika, kuputsika kunoumbwa nenhamba yakawanda ye equiaxed dimples, uye nzira yekuputsika inoshandurwa kubva kune brittle fracture kusvika kune ductile fracture.

Nguva yekutumira: Nov-30-2024