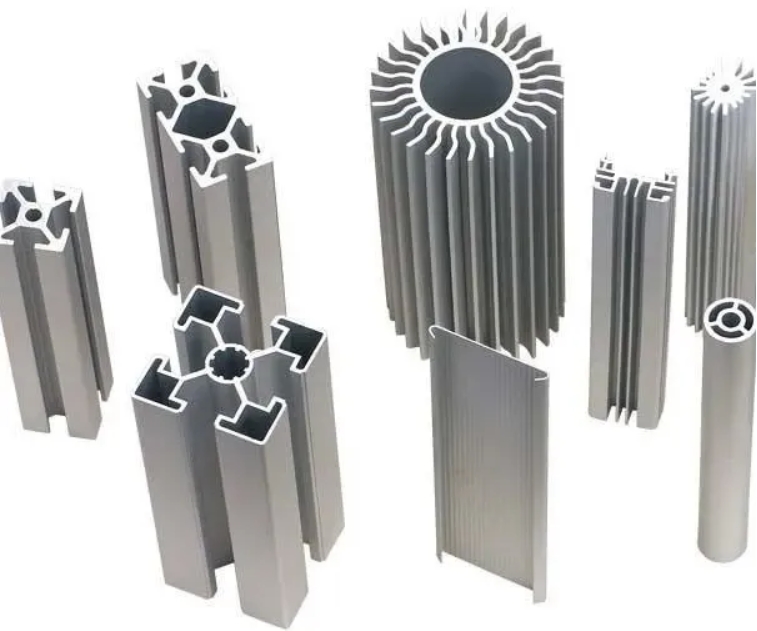

Aluminium chinhu chinowanzo tsanangurwa cheextrusion uye chimiro profiles nekuti ine michina zvimiro zvinoita kuti ive yakanaka yekugadzira uye kuumba simbi kubva mubillet zvikamu. Iyo yakakwira ductility yealuminium inoreva kuti simbi inogona kuumbwa zviri nyore kuita akasiyana-siyana-zvikamu pasina kushandisa simba rakawanda mukugadzira kana kugadzira maitiro, uye aruminiyamu zvakare ine inonyungudika inosvika hafu yesimbi yakajairika. Zvose zviri zviviri izvi zvinoreva kuti extrusion aluminium profile process ishoma simba, izvo zvinoderedza maturusi uye mari yekugadzira. Chekupedzisira, aluminium inewo yakakwira simba kune huremu reshiyo, ichiita sarudzo yakanaka kwazvo yemaindasitiri ekushandisa.

Sechigadzirwa cheiyo extrusion process, yakanaka, inenge isingaonekwe mitsara dzimwe nguva inogona kuoneka pamusoro peiyo mbiri. Izvi zvinokonzerwa nekuumbwa kwezvishandiso zvekubatsira panguva yeextrusion, uye mamwe marapirwo epamusoro anogona kutsanangurwa kubvisa mitsara iyi. Kuti uvandudze kupera kwepamusoro kwechikamu cheprofile, akati wandei echipiri epamusoro ekurapa mashandiro akadai sekugaya kumeso anogona kuitwa mushure meiyo huru extrusion yekugadzira maitiro. Aya machining mashandiro anogona kutsanangurwa kuti avandudze iyo geometry yepasi kuti ivandudze iyo chikamu chimiro nekudzikisa iyo yakazara pamusoro roughness yeiyo extruded profile. Mishonga iyi inowanzo tsanangurwa mumashandisirwo apo panodiwa nzvimbo chaiyo yechikamu kana kuti nzvimbo dzekubatana dzinofanira kudzorwa zvakasimba.

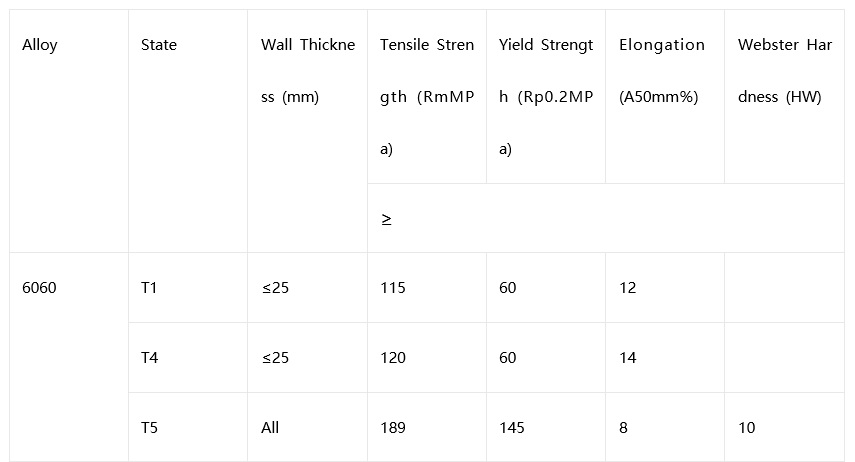

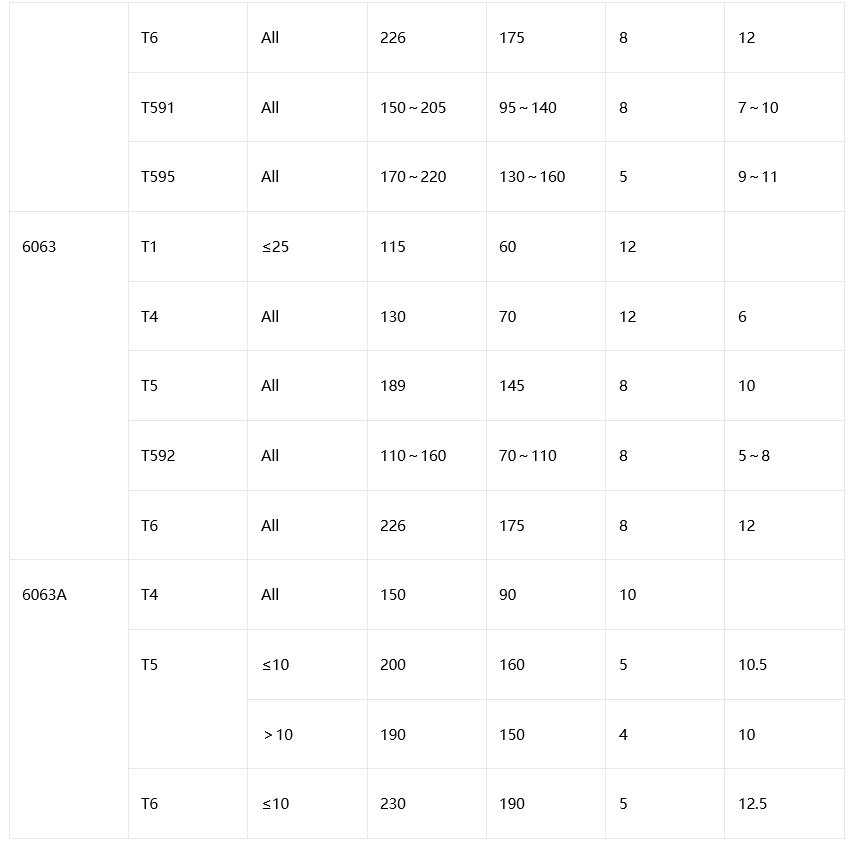

Tinowanzoona mbiru yezvinhu yakanyorwa ne6063-T5/T6 kana 6061-T4, nezvimwewo. Iyo 6063 kana 6061 muchiratidzo ichi ndiyo mhando yealuminium profile, uye T4/T5/T6 ndiyo mamiriro ealuminium profile. Saka musiyano uripo pakati pavo ndeupi?

Semuyenzaniso: Zvichitaurwa zviri nyore, 6061 aruminiyamu mbiri ine simba riri nani uye kucheka kuita, nekuomarara kwepamusoro, zvakanaka weldability uye kushomeka kwekudzivirira; 6063 aluminiyamu mbiri ine purasitiki iri nani, iyo inogona kuita kuti zvinhu zvibudirire zvakanyanya, uye panguva imwe chete zvine simba repamusoro rekusimba uye kusimba kwegoho, inoratidza zviri nani kutyoka kuomarara, uye ine simba rakawanda, kusapfeka, kusagadzikana uye kupisa kwakanyanya.

T4 inoti:

mhinduro kurapwa + kuchembera kwechisikigo, ndiko kuti, iyo aluminiyamu mbiri yakatonhodzwa mushure mekuburitswa kubva kune extruder, asi isina kuchembera muchoto chekuchembera. Iyo aluminiyamu mbiri isati yachembera ine yakaderera kuomarara uye yakanaka deformability, iyo yakakodzera kune gare gare kukotama uye kumwe kugadzirisa deformation.

T5 nyika:

mhinduro kurapwa + isina kukwana chakagadzirwa kuchembera, ndiko kuti, pashure mhepo kutonhora quenching pashure extrusion, uye ipapo akatamisirwa kuchembera choto kuramba ichidziya anenge 200 madhigirii kwemaawa 2-3. Iyo aruminiyamu mune ino nyika ine kuoma kwakanyanya uye imwe dhigirii yekuremara. Ndiyo inonyanya kushandiswa mumadziro emaketeni.

T6 nyika:

mhinduro kurapwa + kuchembera kwakakwana kwekugadzira, ndiko kuti, mushure mekutonhora kwemvura kudzima mushure meextrusion, kuchembera kwekugadzira mushure mekudzima kwakakwira kupfuura tembiricha yeT5, uye nguva yekuvharira zvakare yakareba, kuitira kuti uwane yakakwirira kuoma mamiriro, ayo akakodzera kune dzimwe nguva dzinenge dzakakwirira zvinodiwa zvekuoma kwezvinhu.

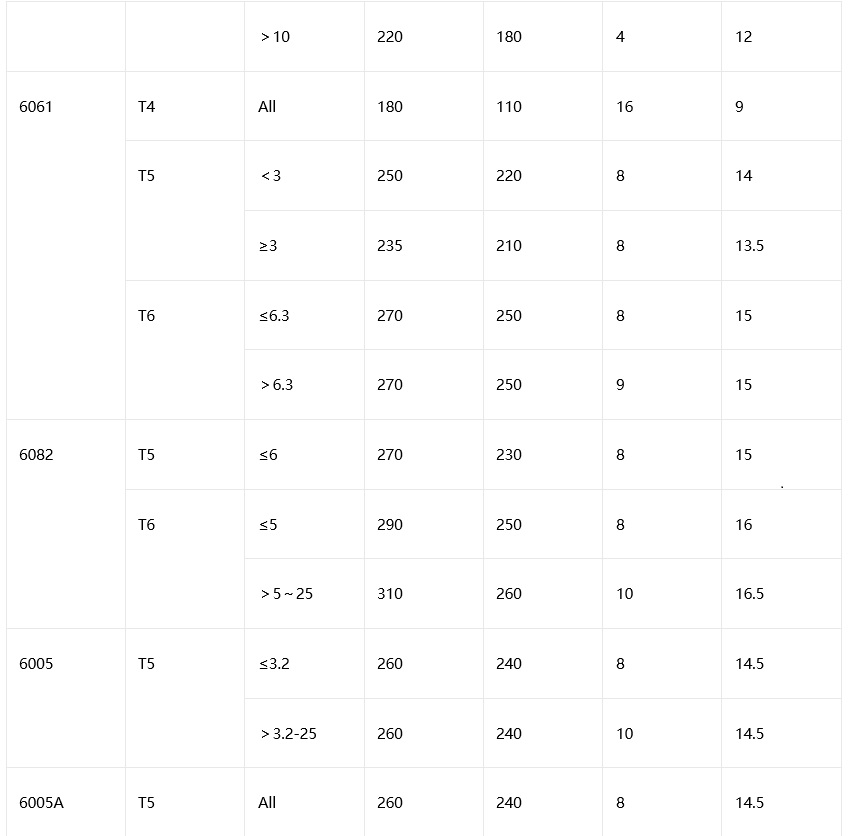

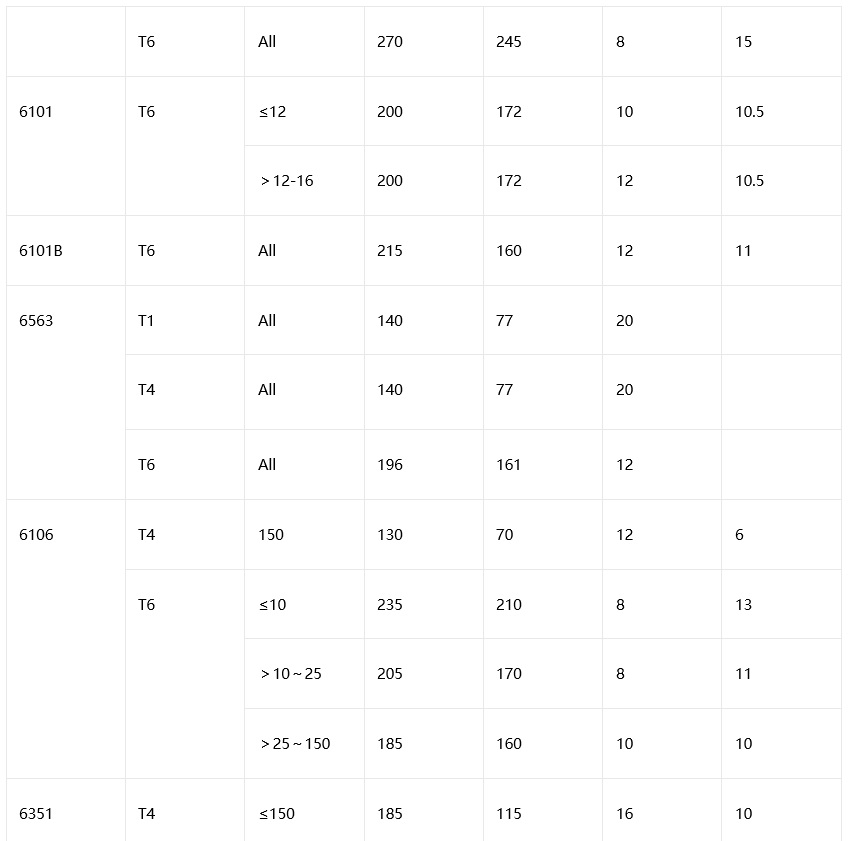

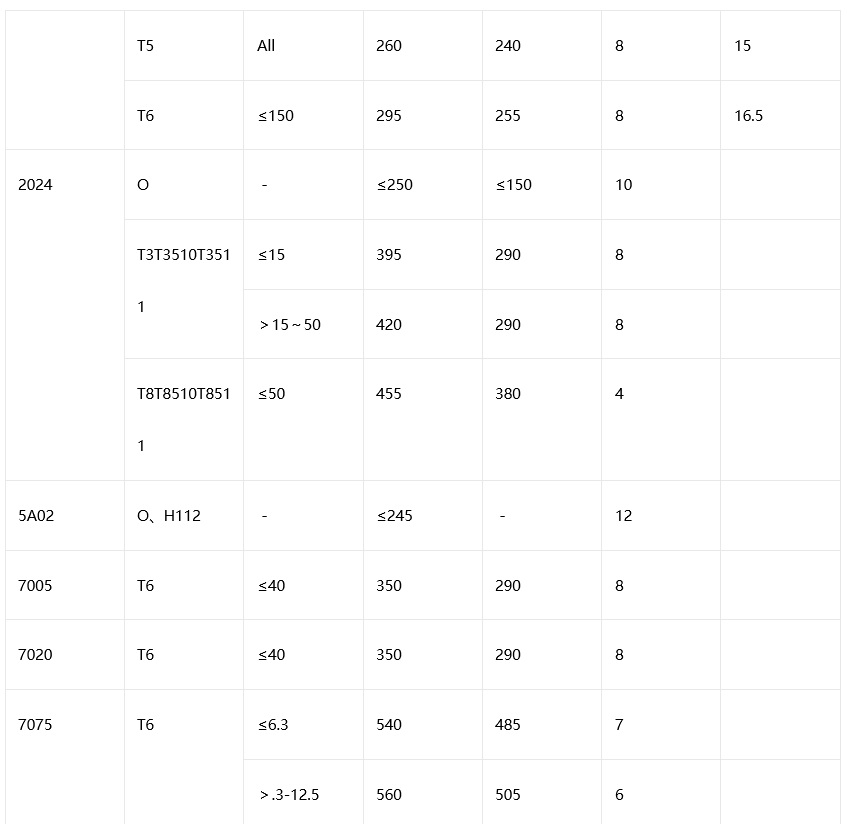

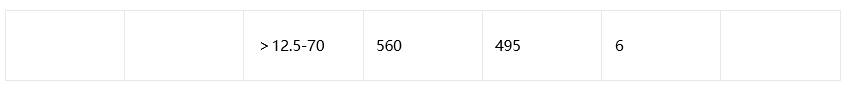

Iwo emakanika zvimiro zvealuminium profiles ezvakasiyana zvinhu uye nyika dzakasiyana zvinotsanangurwa mutafura pazasi:

Goho simba:

Ndiyo muganho wegoho wemidziyo yesimbi kana ichibereka, ndiko kuti, kushushikana kunopesana ne micro plastic deformation. Kune zvigadzirwa zvesimbi zvisina goho riri pachena, kukosha kwekunetseka kunoburitsa 0.2% yakasara deformation inotarwa seyegoho muganhu, iyo inonzi inogadziriswa goho muganhu kana simba regoho. Masimba ekunze makuru kupfuura muganhu uyu achaita kuti zvikamu zvikundikane zvachose uye hazvigone kudzoserwa.

Tensile simba:

Kana aruminiyamu ichibereka kune imwe nhanho, kugona kwayo kuramba deformation kunowedzera zvakare nekuda kwekugadziriswa kwemukati zviyo. Kunyange zvazvo deformation inokura nokukurumidza panguva ino, inogona kuwedzera chete nekuwedzera kwekunetseka kusvikira kushungurudzika kwasvika pakukosha kwepamusoro. Mushure meizvozvo, kugona kweiyo profil kuramba deformation kwakadzikira zvakanyanya, uye hombe yepurasitiki deformation inoitika panzvimbo isina simba. Muchinjikwa-chikamu chemuenzaniso pano unoderera nekukurumidza, uye mitsipa inoitika kusvikira yaputsika.

Webster kuomarara:

Nheyo yekutanga yekuomarara kweWebster ndeye kushandisa inodzimwa yekumanikidza tsono yeimwe chimiro kudzvanya mukati meiyo sampuli pasi pesimba rechitubu chakajairwa, uye kutsanangura kudzika kwe0.01MM seWebster kuomarara unit. Kuoma kwezvinhu kunopesana nehupamhi hwekupinda. Kudzika kudzika kwekupinda, kunowedzera kuoma, uye zvakasiyana.

Plastic deformation:

Iyi imhando ye deformation isingagoni kuzvigadzirisa. Kana zvigadzirwa zveinjiniya uye zvikamu zvinoremerwa kupfuura elastic deformation renji, deformation yekusingaperi ichaitika, ndiko kuti, mushure mekubviswa kwemutoro, deformation isingadzokeri kana yasara deformation ichaitika, inova plastiki deformation.

Nguva yekutumira: Oct-09-2024