Chikamu.1 dhizaini inonzwisisika

Iyo mold inonyanya kugadzirwa maererano nezvinodiwa zvekushandisa, uye chimiro chayo dzimwe nguva hachigone kuve chakakwana uye chakaenzana symmetrical.Izvi zvinoda kuti mugadziri atore matanho anobudirira paanenge achigadzira mold pasina kukanganisa kushanda kwechigadziro, uye edza kubhadhara maitiro ekugadzira, kunzwisisika kwechimiro uye symmetry ye geometric shape.

(1) Edza kudzivirira makona akapinza uye zvikamu zvine misiyano yakakura mukukora

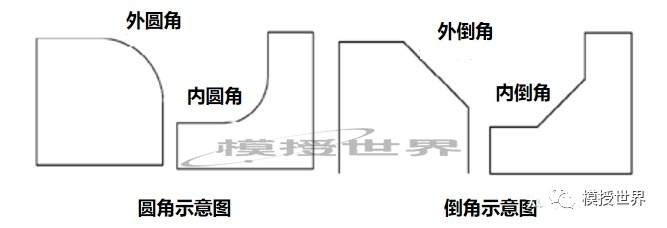

Panofanira kuva neshanduko yakatsetseka pakusangana kwezvikamu zvakakora uye zvitete zve mold.Izvi zvinogona kunyatsogadzirisa kusiyana kwekushisa kwepamuchinjikwa-chikamu che mold, kuderedza kushushikana kwekushisa, uye panguva imwechete kuderedza kusapindirana kwekushanduka kwemavara pamuchinjikwa, uye kuderedza kushushikana kwemuviri.Mufananidzo 1 unoratidza kuti mold inotora shanduko fillet uye shanduko cone.

(2) Zvakakodzera kuwedzera maitiro maburi

Kune dzimwe molds dzisingakwanisi kuvimbisa yunifomu uye symmetrical cross chikamu, zvakakosha kushandura iyo isiri-kuburikidza negomba kuita gomba kana kuwedzera mamwe maitiro maburi zvakakodzera pasina kukanganisa kushanda.

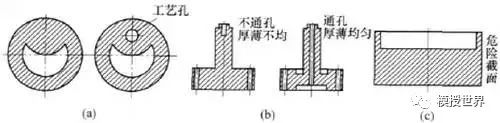

Mufananidzo 2a unoratidza kufa negomba rakamanikana, iro rinozoremara sekuratidzwa nemutsara une doti mushure mekudzima.Kana maburi maviri ekugadzirisa anogona kuwedzerwa mukugadzirwa (sezvinoratidzwa mumufananidzo 2b), kusiyana kwekushisa kwepamuchinjikwa panguva yekudzima kunoderedzwa, kushushikana kwekushisa kunoderedzwa, uye deformation inovandudzwa zvakanyanya.

(3) Shandisa zvakavharwa uye symmetrical zvimiro zvakanyanya sezvinobvira

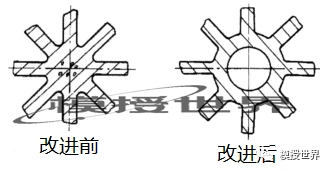

Kana chimiro che mold chakavhurika kana asymmetrical, kugovaniswa kwekunetseka mushure mekudzima hakuna kuenzana uye zviri nyore kukanganisa.Naizvozvo, kune zvakajairika deformable trough molds, kusimbiswa kunofanirwa kuitwa kusati kwadzima, uyezve kugurwa mushure mekudzima.The chidyiro workpiece inoratidzwa Figure 3 pakutanga akaremara paR pashure quenching, uye akasimbisa (yakachochonywa chikamu Figure 3), anogona zvinobudirira kudzivirira quenching deformation.

(4) Gamuchira chimiro chakasanganiswa, ndiko kuti, kugadzira mold yekutsaudzira, patsanura epamusoro uye yepasi molds emhando yekutsaudzira, uye patsanura iyo inofa uye punch.

Kune hombe inofa ine chimiro chakaoma uye saizi> 400mm uye zvibhakera zvine ukobvu diki uye kureba kureba, zviri nani kutora yakasanganiswa chimiro, kurerutsa iyo yakaoma, kuderedza hombe kusvika kudiki, uye kushandura mukati mukati me mold kusvika kunze. , iyo isiri nyore chete kupisa uye kutonhora kugadzirisa.

Paunenge uchigadzira chimiro chakasanganiswa, chinofanirwa kuomeswa zvinoenderana neinotevera misimboti pasina kukanganisa kurongeka kwakaringana:

- Gadzirisa ukobvu kuitira kuti muchinjiko-chikamu che mold ine zvakasiyana-siyana-zvikamu zvakachinjika zviri yunifomu mushure mekuora.

- Kuora munzvimbo umo kushushikana kuri nyore kugadzira, paradzira kushushikana kwayo, uye kudzivirira kutsemuka.

- Batira pamwe neburi rekuita kuti chimiro chienzane.

- Zviri nyore kutonhora uye kupisa kugadzirisa uye nyore kuunganidza.

- Chinhu chinonyanya kukosha ndechekuvimbisa usability.

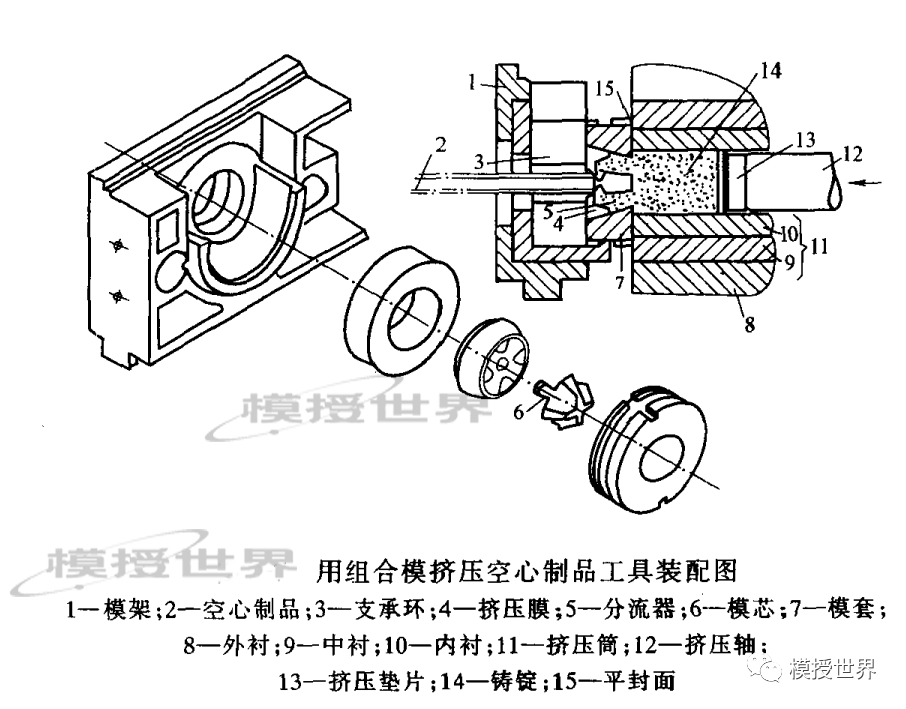

Sezvinoratidzwa mumufananidzo 4, ifa huru.Kana iyo yakabatanidzwa chimiro yakagamuchirwa, kwete chete kupisa kwekupisa kuchava kwakaoma, asiwo mhango ichaderera zvisinganzwisisiki mushure mekudzima, uye kunyange kukonzera kusaenzana uye kukanganisa kwendege yekucheka, izvo zvichange zvakaoma kugadzirisa mukugadzirisa kunotevera., saka, chimiro chakabatanidzwa chinogona kugamuchirwa.Maererano nemutsara wakatsetseka muMufananidzo 4, wakakamurwa kuita zvikamu zvina, uye mushure mekurapa kwekupisa, vanounganidzwa uye vanoumbwa, uye vobva vavhuniwa uye vanofananidzwa.Izvi hazvisi kungorerutsa kurapwa kwekupisa, asi zvakare kugadzirisa dambudziko re deformation.

Chikamu.2 kusarudzwa kwezvinhu zvakarurama

Kupisa kurapwa deformation uye kuputika kunoenderana zvakanyanya nesimbi inoshandiswa uye hunhu hwayo, saka inofanirwa kuve yakavakirwa pakuita zvinodiwa zve mold.Kusarudzwa kunonzwisisika kwesimbi kunofanira kufunga nezve kurongeka, chimiro uye ukuru hwe mold, pamwe chete nemasikirwo, huwandu uye nzira dzekugadzirisa zvinhu zvakagadziriswa.Kana iyo yakawanda mold isina deformation uye chaiyo zvinodiwa, carbon tool steel inogona kushandiswa maererano nekuderedza mari;nokuda kwezvikamu zviri nyore kuremara uye zvakatsemuka, alloy tool simbi ine simba rakakwirira uye inononoka kudzika midzi uye kutonhora kumhanya kunogona kushandiswa;Semuenzaniso, chinhu chemagetsi chinofa pakutanga chakashandiswa T10A simbi, deformation yakakura uye nyore kutsemuka mushure mekudzima kwemvura uye kutonhora kwemafuta, uye alkali bhati yekudzima mhango haisi nyore kuomesa.Ikozvino shandisa 9Mn2V simbi kana CrWMn simbi, iyo yekudzima kuomarara uye deformation inogona kusangana nezvinodiwa.

Zvinogona kuonekwa kuti kana deformation ye mold yakagadzirwa nekabhoni simbi isingasviki zvinodiwa, ichiri mari-inoshanda kushandisa alloy simbi yakadai se9Mn2V simbi kana CrWMn simbi.Kunyangwe mutengo wezvinhu wakakwira zvishoma, dambudziko re deformation uye kupaza rinogadziriswa.

Paunenge uchisarudza zvinhu nemazvo, zvinodikanwa zvakare kusimbisa kuongororwa uye manejimendi ezvigadzirwa zvekudzivirira mold kupisa kurapwa kuparuka nekuda kwekuremara kwezvinhu.

Yakarongedzwa naMay Jiang kubva kuMAT Aluminium

Nguva yekutumira: Sep-16-2023